Desulfurization and dust removal purification device for circulatory flue gas of dry quenching pre-storage section

A technology of circulating flue gas and purification equipment, applied in coke ovens, coke cooling, chemical instruments and methods, etc., can solve the problem of less development of CDQ pre-storage section, and achieve stable and normal production, simple desulfurization system, The effect of convenient operation and maintenance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] The present invention will be described in detail below in conjunction with the accompanying drawings, but it should be pointed out that the implementation of the present invention is not limited to the following embodiments.

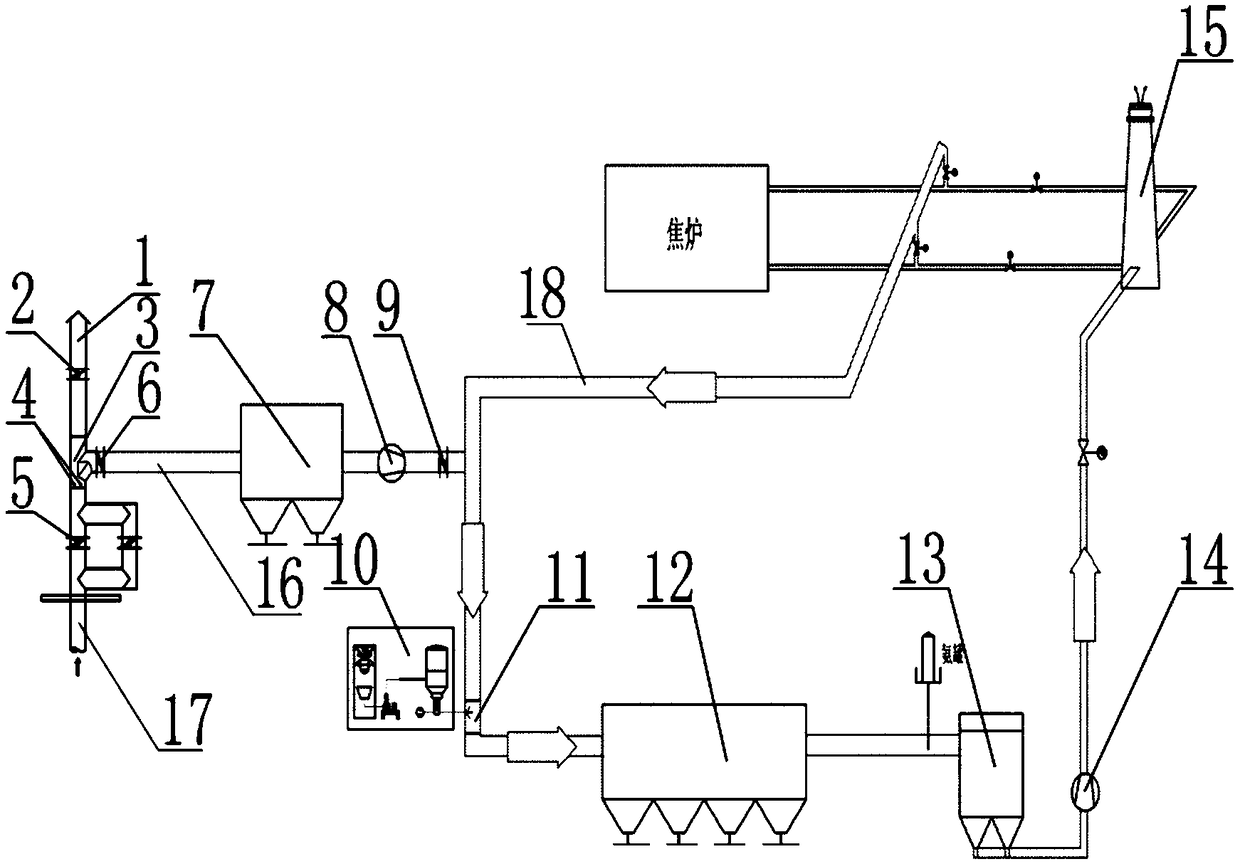

[0031] See figure 1 A CDQ pre-storage section circulating flue gas desulfurization and dust removal purification device includes a coke oven flue gas desulfurization and denitrification system and a CDQ pre-storage section circulating flue gas dust removal purification and dispersal system. Coke oven flue gas desulfurization and denitrification system includes coke oven flue gas pipeline 18, desulfurization agent preparation and injection device 10, desulfurization reaction flue 11, bag filter 12, SCR denitrification reactor 13, coke oven booster fan 14, coke Furnace chimney 15 and coke oven flue gas pipeline 18 are connected in turn with desulfurization reaction flue 11, bag filter 12, SCR denitrification reactor 13, coke oven booster fan 14, co...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com