Optimal clean combustion process and system of coal washing slime compound circulating fluidized bed

A combined cycle and clean combustion technology, applied in fluidized bed combustion equipment, fuels burned in molten state, combustion methods, etc., can solve problems such as inability to meet low calorific value combustion requirements, inability to increase fuel combustion efficiency, inability to meet combustion requirements, etc. , to achieve the effect of good load regulation characteristics, low cost, and solve the problem of recycling

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

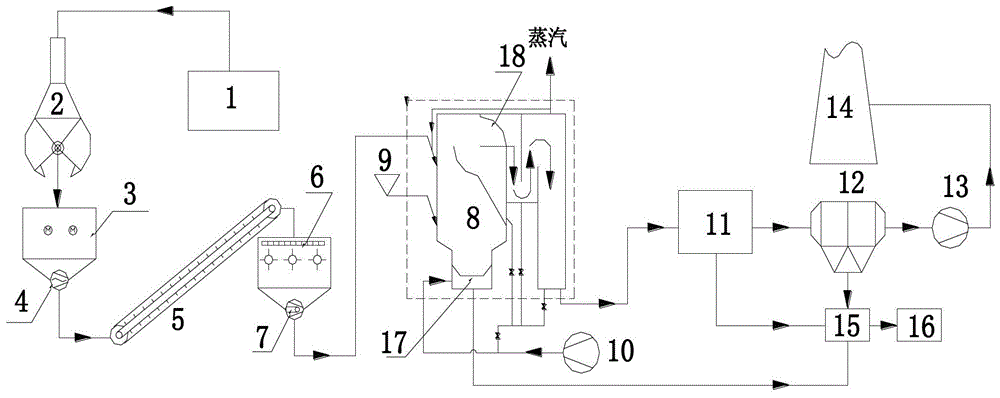

[0030] Such as figure 1 As shown, the combustion system of this embodiment includes: a compound circulating fluidized bed 8, a coal slime storage tank 1, a coal slime feeding bin 3, a double screw feeder 4, a scraper conveyor 5, a mixer 6 and a double Coal washing slime supply source composed of cylinder slime plunger pump 7, secondary combustion loop composed of sequentially connected blower 10, inertial separator 11, dust collector 12 and ash bin 15, wherein: coal washing slime supply source The output end of the compound circulating fluidized bed is connected to the input end of the compound circulating fluidized bed 8, and the output end of the compound circulating fluidized bed 8 is connected to the inertia separator 11 and the ash bin 15 in the secondary combustion loop respectively, and the compound circulating fluidized bed 8 The recovery end is connected with the inertial separator 11 and the air blower 10 in the secondary combustion loop, and the lower ash falling po...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com