Industrial boiler system and method for clean combustion of carbon particles

An industrial boiler and clean combustion technology, which is applied in the fields of coal clean combustion, carbon particle clean combustion, and carbon particle clean combustion industrial boiler system, can solve the problem of high labor intensity for operators, difficulty in pollutant discharge, and low utilization rate of coal such as lignite and other issues, to achieve the effect of saving equipment investment, reducing NOX, and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

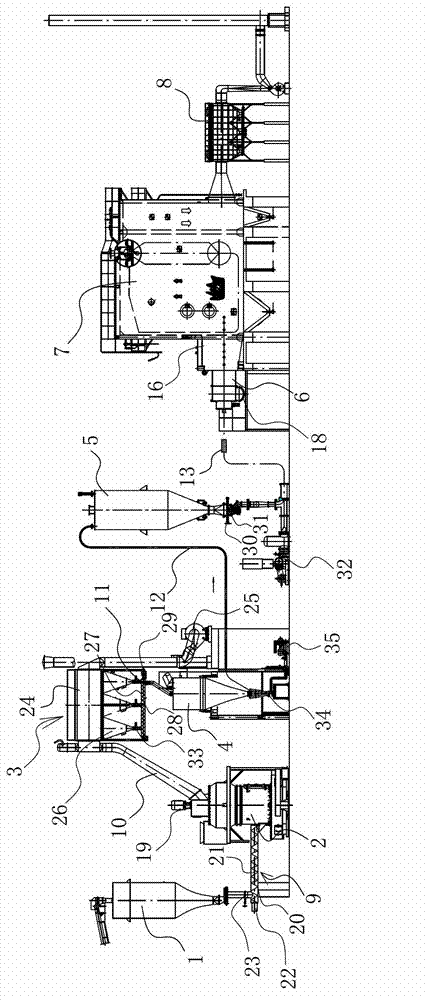

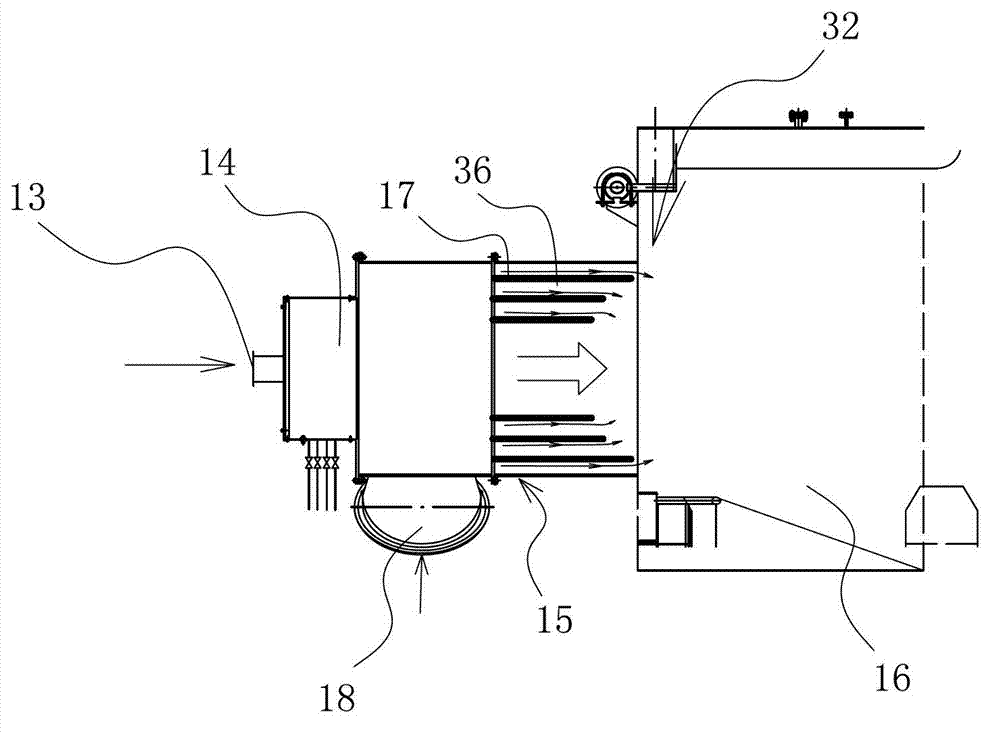

[0022] like figure 1As shown, the carbon particle clean combustion industrial boiler system includes a raw coal bunker 1 connected in sequence, a clean carbon particle pulverizer 2, a powder collection device 3, a first clean carbon particle storage tower 4, a second clean carbon particle storage tower 5, High-efficiency carbon particle burner 6, low-temperature combustion industrial boiler 7 and dust removal equipment 8. The raw coal bunker 1 is connected to the clean carbon particle pulverizer 2 through the first conveying mechanism 9, and the clean carbon particle pulverizer 2 is connected to the powder collecting equipment 3 through the conveying pipeline 10, and the described powder collecting equipment 3 passes through the second The conveying mechanism 11 is connected to the first clean carbon particle storage tower 4, and the first clean carbon particle storage tower 4 is connected to the second clean carbon particle storage tower 5 through the pulverized coal delivery...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com