Ignition gun capable of detecting ignition flame

A technology for ignition guns and flames, which is applied in the field of ignition guns, and can solve problems such as no flame monitoring, threats to the personal safety of operators, and impact on accuracy, so as to avoid hidden dangers of safety accidents, simple detection structure, and prolong service life.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

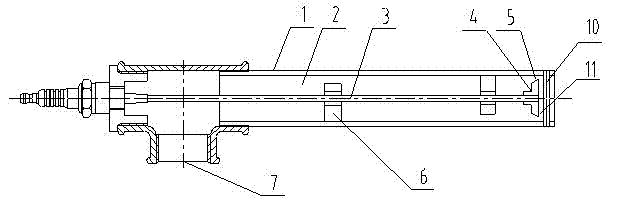

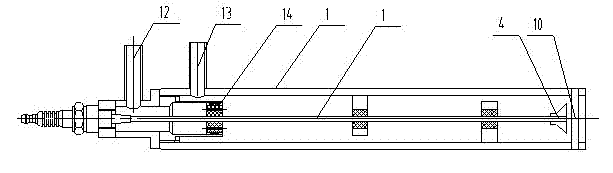

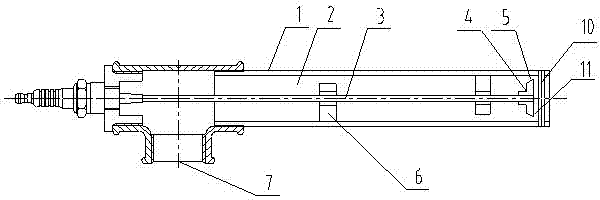

[0014] The ignition gun that can detect ignition flame of the present invention comprises ignition power supply and gun barrel 1, and the surface layer of gun barrel 1 or whole is the metal gun barrel that conductive metal material is made of, and the inside of gun barrel 1 is cavity 2, and The ignition needle 3 connected to the ignition power supply is arranged in the cavity 2, one end of the ignition needle 3 is connected to the ignition power supply, and the other end is provided with an ignition electrode 4, and a certain width dimension is formed between the side of the ignition electrode 4 and the inner wall of the gun barrel 1. The ignition chamber 5, the width of the ignition chamber 5 is about 3mm, after the ignition power supply (high voltage) is communicated with the ignition needle 3 and the ignition electrode 4 through the corresponding control switch, the side of the ignition electrode 4 and the inner wall of the gun barrel 1 are in the ignition chamber. Discharge...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com