Method for oil shale integral utilization

A technology for oil shale and oil shale semi-coke, which is applied in the field of comprehensive utilization of oil shale, can solve the problem of failure to optimize, rationally, economically and efficiently utilize oil shale resources, difficult to burn oil shale with low calorific value, and mechanical incompleteness. Combustion heat loss and other problems, to avoid the increase of water content, low cost, high economic effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

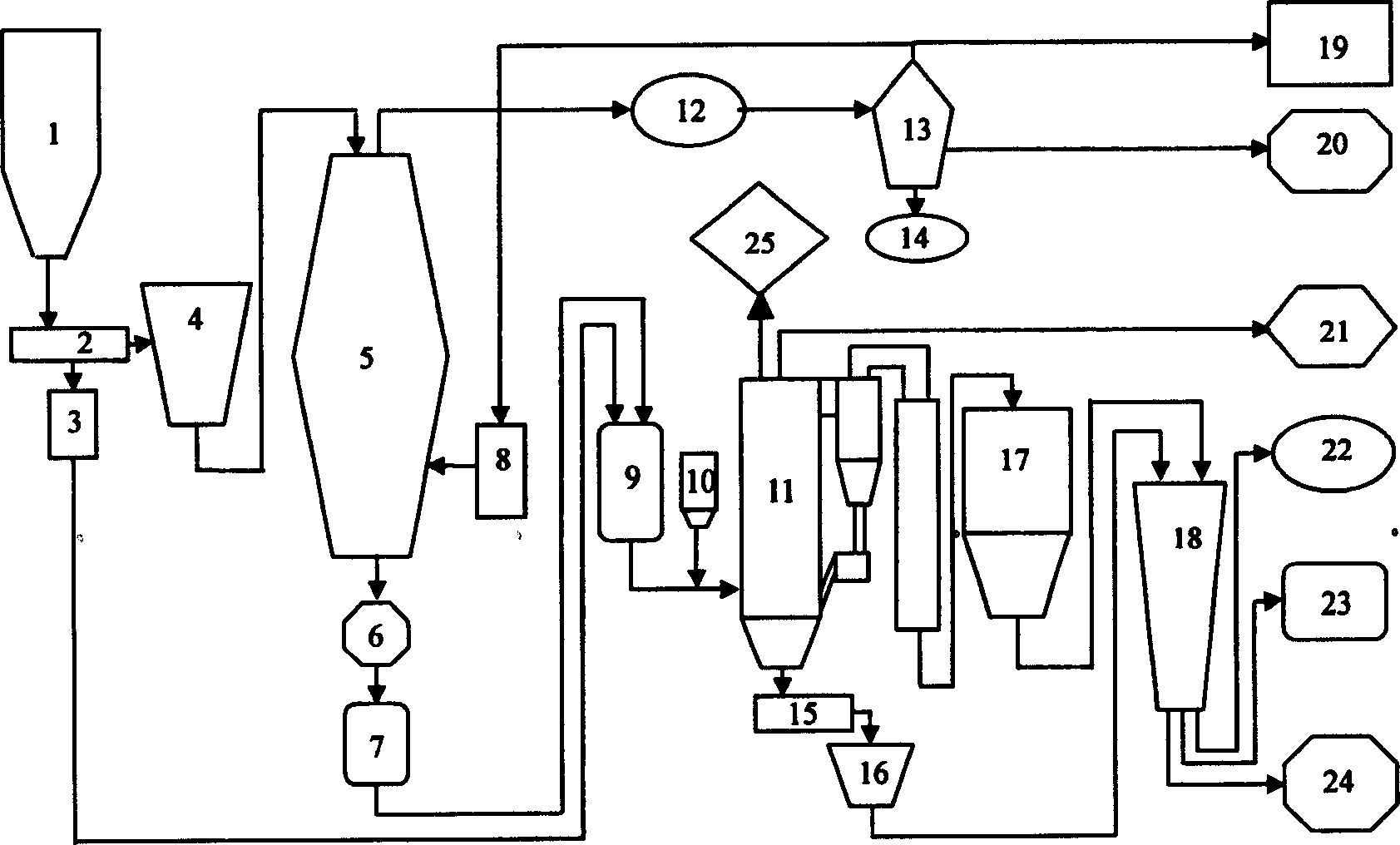

[0010] The technical process of the present invention will be further described below in conjunction with the accompanying drawings.

[0011] figure 1 It is technical process of the present invention. Such as figure 1As shown, the oil shale used for refining shale oil with a particle size of 0-80mm is sent into the oil shale hopper 1, and the oil shale fine slag with a particle size of less than 8mm is sent into the oil shale hopper through the crushing and screening machine 2. Shale fine slag waste material hopper 3, the oil shale with a particle size greater than 8mm is sent into the oil shale hopper 4, and the conveyor sends the oil shale with a particle size greater than 8mm from the top to the vertical oil shale retort furnace 5 for carbonization , the carbonization temperature of the oil shale carbonization furnace is preferably 450-550°C, the heat required for the carbonization comes from the heating furnace 8, the gas required for the heating furnace comes from the s...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com