Fiber filter membrane preparation device and preparation method thereof

A technology of fiber filtration membrane and preparation device, which is used in fiber processing, textiles and papermaking, non-woven fabrics, etc., can solve the problems of low filtration resistance, inability to directly produce porous structure fibers, and low mass production, and achieve low filtration resistance. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

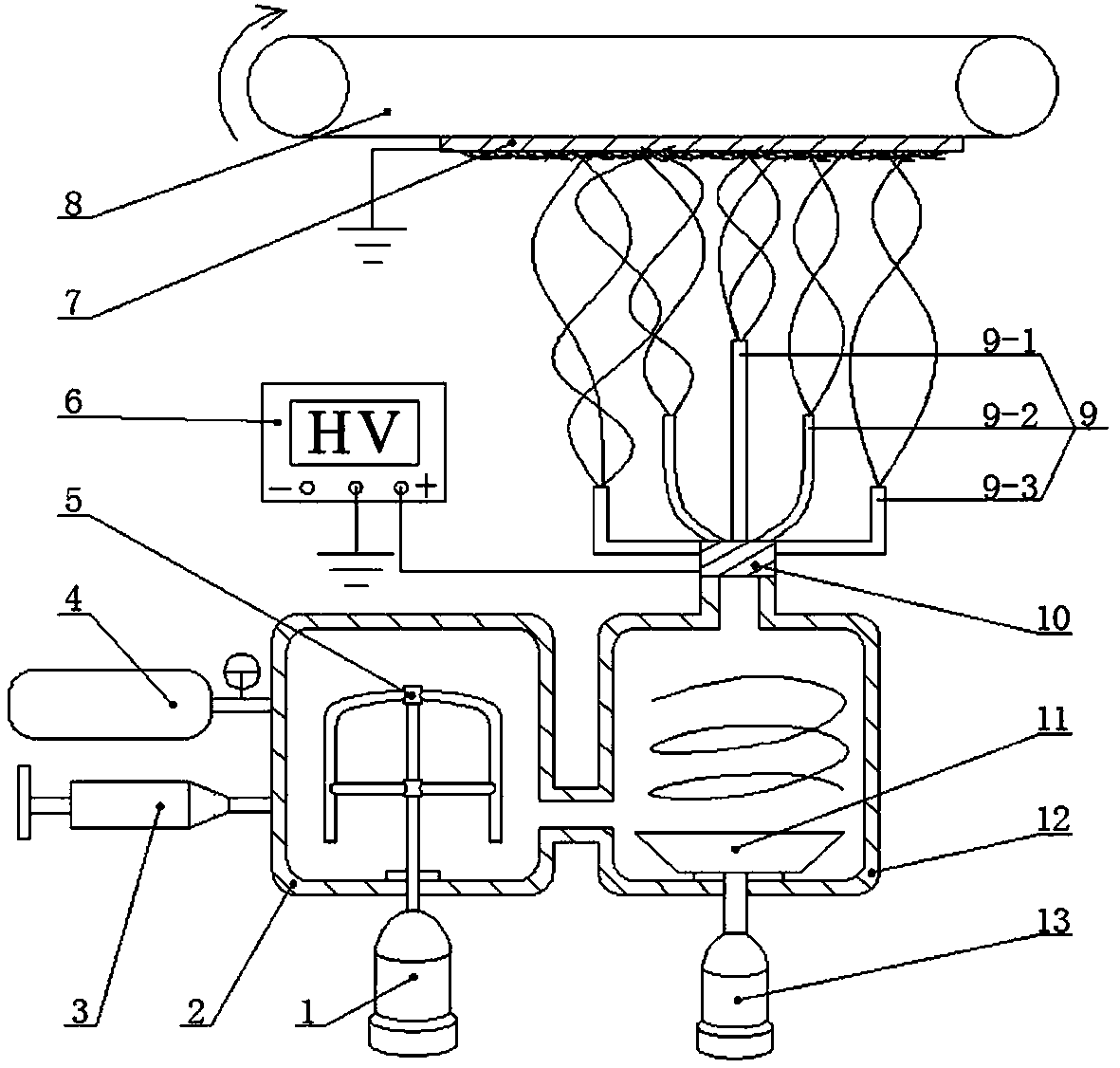

[0039] In conjunction with the preparation device provided above, the preparation method for preparing the fiber filter membrane is set forth:

[0040] The solution used is PEO solution with a concentration of 15%, the solute is PEO, and the solvent is alcohol and distilled water (volume ratio is 1:1).

[0041] Step 1. Press figure 1 Build a preparation device, the inner diameter of the nozzle is 350 μm, the distance between the first nozzle 9-1 and the substrate 7 is 20 cm, the distance between the second nozzle 9-2 and the substrate 7 is 35 cm, and the distance between the third nozzle 9-3 and the substrate 7 is 45 cm;

[0042] Step 2. Fill the stirring chamber 2 and the mixing chamber 12 with the solution;

[0043] Step 3. Set the flow rate of the solution pumped by the liquid supply device 3 to 35ml / hr, and the solution starts to be pumped to the stirring chamber 2;

[0044] Step 4. Set the flow rate of the gas pumped by the gas supply device 4 to 4ml / hr, the frequency t...

Embodiment 2

[0052] In conjunction with the preparation device provided above, the preparation method for preparing the fiber filter membrane is set forth:

[0053] The solution used is PVDF solution with a concentration of 20%, the solute is PVDF, and the solvent is DMF and acetone (volume ratio is 1:1).

[0054] Step 1. Press figure 1 Build a preparation device, the inner diameter of the nozzle is 210 μm, the distance between the first nozzle 9-1 and the substrate 7 is 15 cm, the distance between the second nozzle 9-2 and the substrate 7 is 25 cm, and the distance between the third nozzle 9-3 and the substrate 7 is 30 cm;

[0055] Step 2. Fill the stirring chamber 2 and the mixing chamber 12 with the solution;

[0056] Step 3. Set the flow rate of the solution pumped by the liquid supply device 3 to 25ml / hr, and the solution starts to be pumped to the stirring chamber 2;

[0057] Step 4. Set the flow rate of the gas pumped by the gas supply device 4 to 3.5ml / hr, the frequency to 3Hz, a...

Embodiment 3

[0065] In conjunction with the preparation device provided above, the preparation method for preparing the fiber filter membrane is set forth:

[0066] The solution used is PVDF solution with a concentration of 16%, the solute is PVDF, and the solvent is DMF and acetone (volume ratio is 1:1).

[0067] Step 1. Press figure 1 Build a preparation device, the inner diameter of the nozzle is 210 μm, the distance between the first nozzle 9-1 and the substrate 7 is 10 cm, the distance between the second nozzle 9-2 and the substrate 7 is 20 cm, and the distance between the third nozzle 9-3 and the substrate 7 is 30 cm;

[0068] Step 2. Fill the stirring chamber 2 and the mixing chamber 12 with the solution;

[0069] Step 3. Set the flow rate of the solution pumped by the liquid supply device 3 to 20ml / hr, and the solution starts to be pumped to the stirring chamber 2;

[0070] Step 4. Set the flow rate of the gas pumped by the gas supply device 4 to 4ml / hr, and the frequency to 3Hz,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com