Preparation method of breathable artificial leather product with moisture absorption and sweat releasing effects

A technology for moisture absorption and perspiration, artificial leather, applied in the field of synthetic leather, can solve the problems of no DMF removal, DMF residues, product safety issues, etc., to achieve the effect of improving product safety factor and reducing DMF residues

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

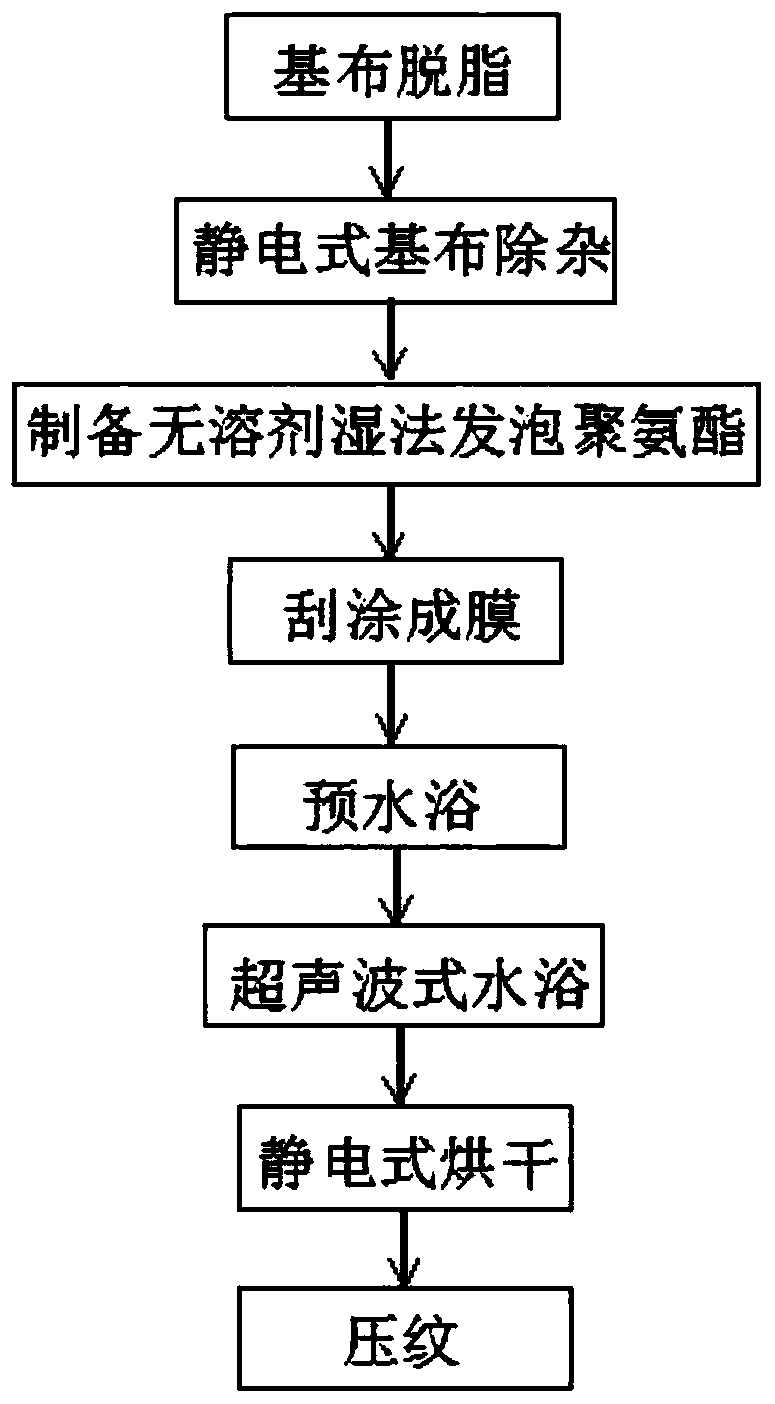

[0047] see figure 1 , a method for preparing a moisture-absorbing and sweat-wicking breathing artificial leather product, the preparation steps of which are:

[0048] Step 1, the base cloth is degreased, and the base cloth is placed in the degreasing equipment for degreasing operation;

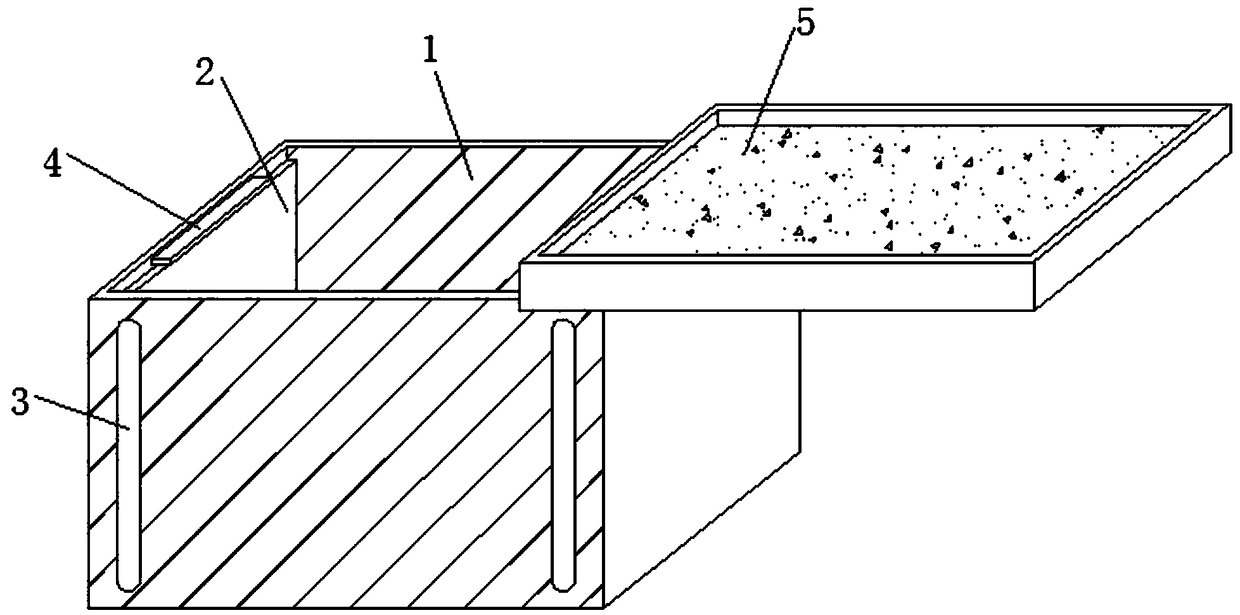

[0049] Step 2, electrostatic base cloth removal, clamping the degreased base cloth with clamps and hanging it in the electrostatic adsorption box 1 for removal of impurities, and performing electrostatic adsorption treatment on the front and back sides of the base cloth;

[0050] Step 3. Prepare solvent-free wet-process foaming polyurethane. In parts by mass, 60 parts of polyols are added to the reaction kettle, then the polyols are dehydrated, and 90 parts of isocyanate, 15 parts of treatment agent and 0.2 parts of catalyst, then reacted at 65°C for 3 hours to obtain solvent-free wet-process foamed polyurethane;

[0051] Step 4: Scrape coating to form a film, using a precision scraper knife...

Embodiment 2

[0067] A method for preparing a moisture-absorbing and sweat-wicking breathing artificial leather product, the preparation steps of which are:

[0068] Step 1, the base cloth is degreased, and the base cloth is placed in the degreasing equipment for degreasing operation;

[0069] Step 2, electrostatic base cloth removal, clamping the degreased base cloth with clamps and hanging it in the electrostatic adsorption box 1 for removal of impurities, and performing electrostatic adsorption treatment on the front and back sides of the base cloth;

[0070] Step 3. Prepare solvent-free wet-process foaming polyurethane. Add 30 parts of polyol to the reaction kettle in parts by mass, then dehydrate the polyol, add 40 parts of isocyanate, 12 parts of treatment agent and 0.1 part of catalyst, the molar ratio of the isocyanate group in the isocyanate to the hydroxyl group in the polyol is 1.5, the treatment agent includes nanoporous moisture-absorbing and sweat-wicking organic polymer powde...

Embodiment 3

[0077] A method for preparing a moisture-absorbing and sweat-wicking breathing artificial leather product, the preparation steps of which are:

[0078] Step 1, the base cloth is degreased, and the base cloth is placed in the degreasing equipment for degreasing operation;

[0079] Step 2, electrostatic base cloth removal, clamping the degreased base cloth with clamps and hanging it in the electrostatic adsorption box 1 for removal of impurities, and performing electrostatic adsorption treatment on the front and back sides of the base cloth;

[0080] Step 3. Prepare solvent-free wet-process foaming polyurethane. Add 40 parts of polyol to the reaction kettle in parts by mass, then dehydrate the polyol, add 50 parts of isocyanate, 14 parts of treatment agent and 0.15 parts of the catalyst, the molar ratio of the isocyanate group in the isocyanate to the hydroxyl group in the polyol is 2.2, the treatment agent includes nanoporous moisture-absorbing and sweat-absorbing organic polym...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com