A transcritical CO with precooler 2 Heat pump system and water circuit two-way valve control method

A heat pump system and control method technology, applied in heat pumps, evaporators/condensers, refrigerators, etc., can solve problems such as reducing system efficiency, and achieve the effect of ensuring rigorous, stable and efficient operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

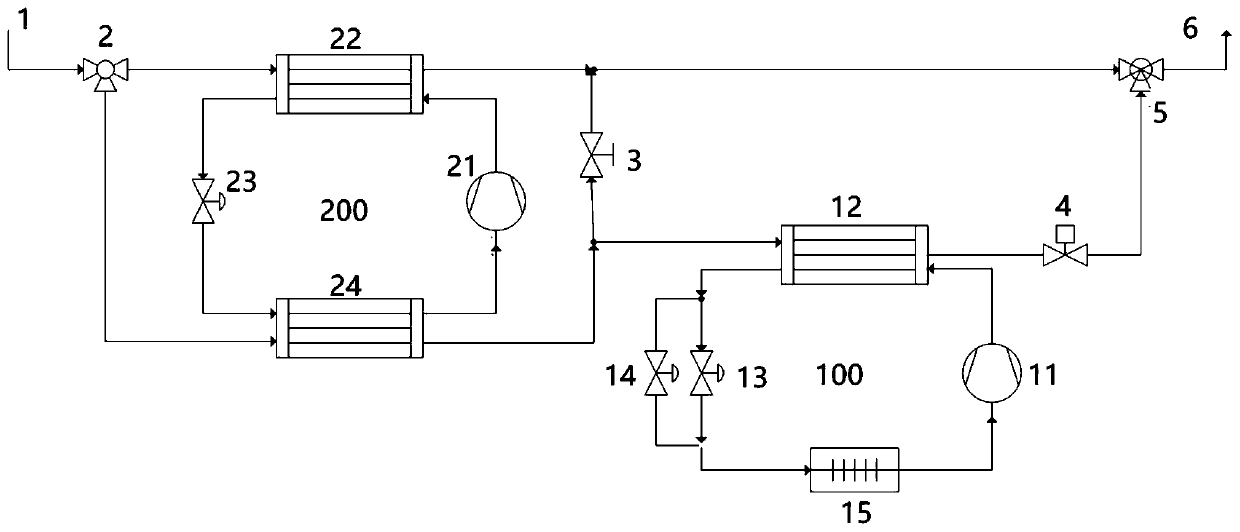

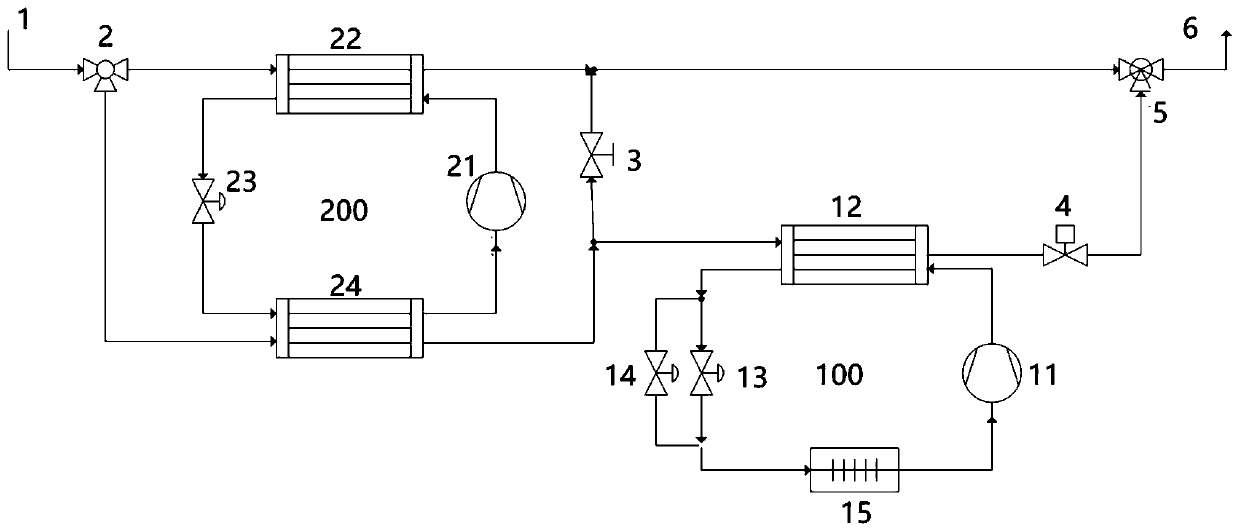

[0045] See figure 1 As shown, the present invention is based on a transcritical CO with a precooler 2 Heat pump system, including circulating water system, CO 2 Heat pump system 100 and pre-cooler system 200.

[0046] The circulating water system includes a system water inlet 1, a three-way water divider valve 2, a waterway bypass valve 3, a waterway two-way regulating valve 4, a three-way water collection valve 5 and a system water outlet 6.

[0047] CO 2 Heat pump system includes CO 2 Compressor 11, CO 2 Gas cooler 12, electronic expansion valve 13, defrost solenoid valve 14, CO 2 Evaporator 15, ambient temperature sensor, evaporation pressure sensor, evaporation fin temperature sensor.

[0048] The pre-cooler system includes a pre-cooling system compressor 21, a pre-cooling system condenser 22, a thermal expansion valve 23, and a pre-cooling system evaporator 24.

[0049] In the present invention, all collection signals and control logic are collected and executed uniformly by the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com