Spraying type enhanced heat exchange flue gas heat exchange device

A technology to enhance heat exchange and flue gas heat exchange, which is applied in the direction of reducing greenhouse gases, climate sustainability, lighting and heating equipment, etc., and can solve the problem of inability to adjust the heat transfer distribution of the flue gas heat exchanger and the large volume of the heat exchanger , poor heat transfer efficiency, etc., to avoid pulsation noise, save resources, and reduce costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 2

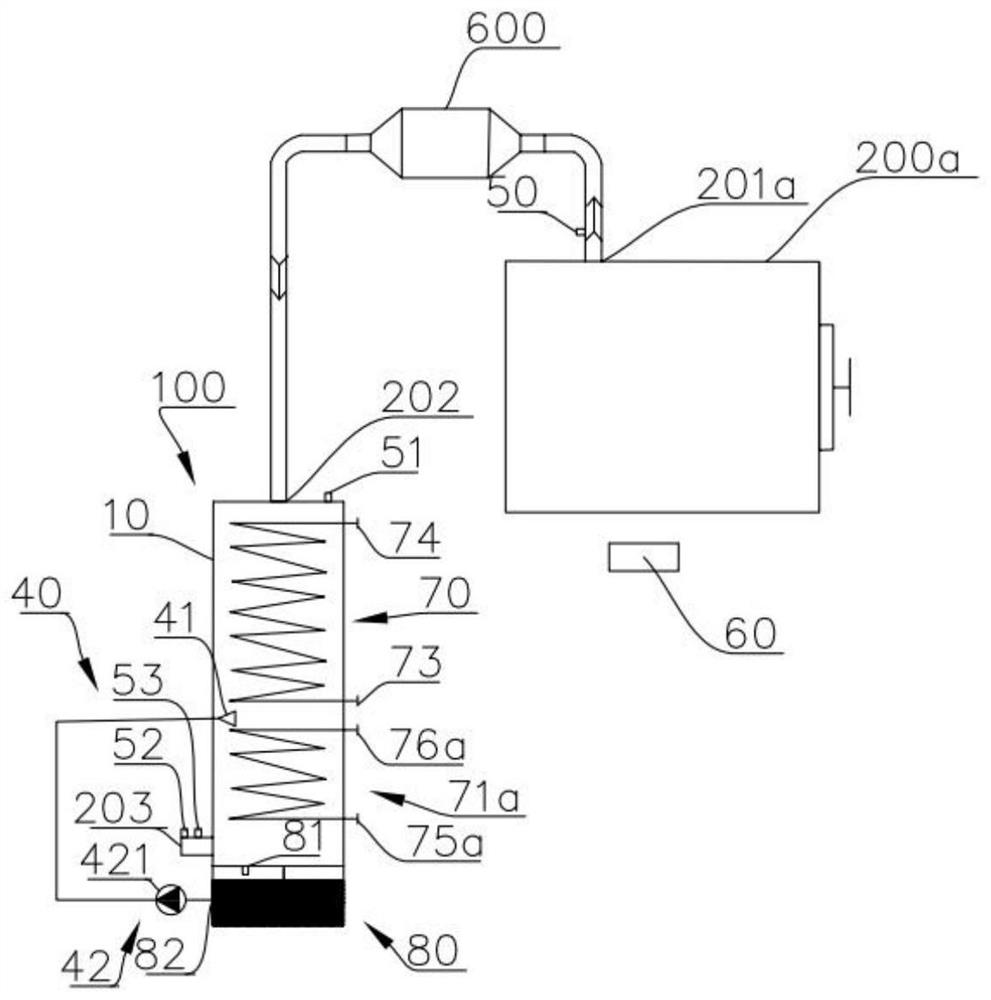

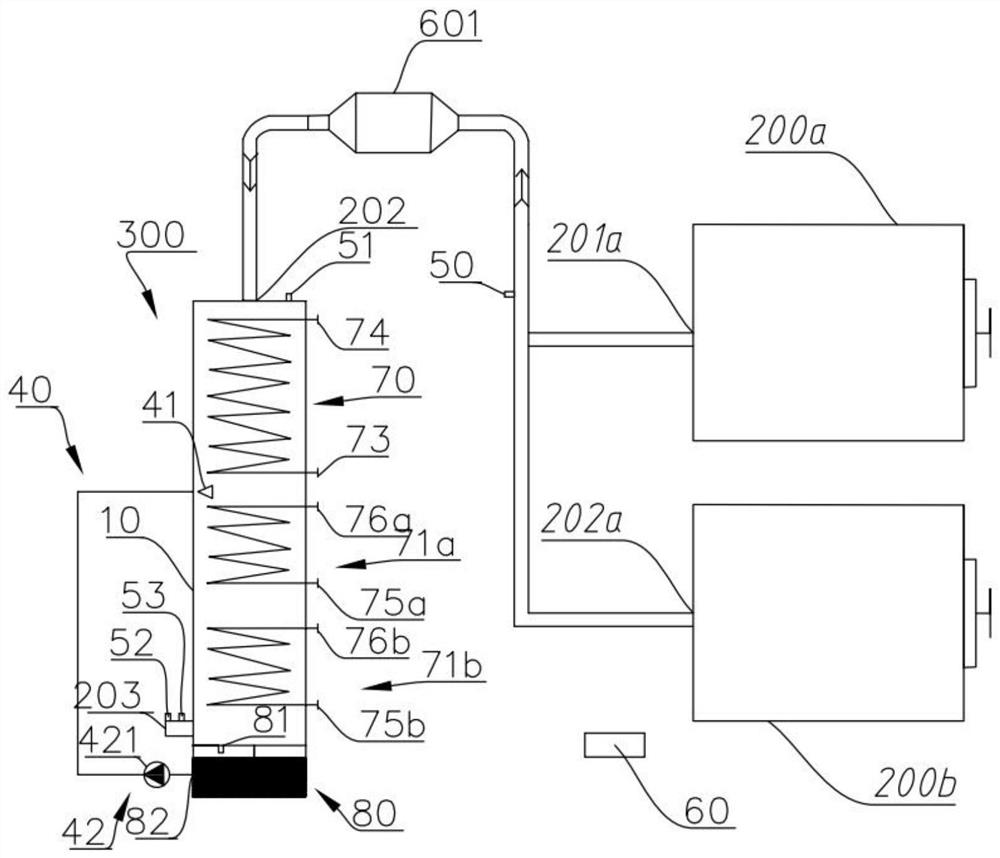

[0054] image 3 It is a structural schematic diagram of a flue gas heat exchange device for spraying enhanced heat exchange in Embodiment 2 of the present invention.

[0055] Such as image 3 As shown, the difference between the present embodiment and the first embodiment is that the spray-type enhanced heat exchange flue gas heat exchange device 200 also has a second refrigerant flue gas heat exchanger 71b. In addition, the gas-air source heat pump unit matched with the spray flue gas heat exchange device 200 also includes an engine 200b.

[0056] The second refrigerant flue gas heat exchanger 71b is installed below the first refrigerant flue gas heat exchanger and between the smoke outlet 203, and has a second refrigerant inlet 75b and a second refrigerant outlet 76b. After the flue gas and condensed water flow through the first refrigerant flue gas heat exchanger 71a, they continue to flow through the second refrigerant flue gas heat exchanger 71b to further cool down and...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com