Liquid crystal Fabry-Perot resonant cavity-based optical fiber hydrophone and manufacturing method thereof

A Poirot resonator and optical fiber hydrophone technology, applied in instruments, measuring devices, and measuring ultrasonic/sonic/infrasonic waves, etc., can solve the problem of low sensitivity and achieve the effects of increased acoustic sensitivity, easy structure, and loud sensitivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

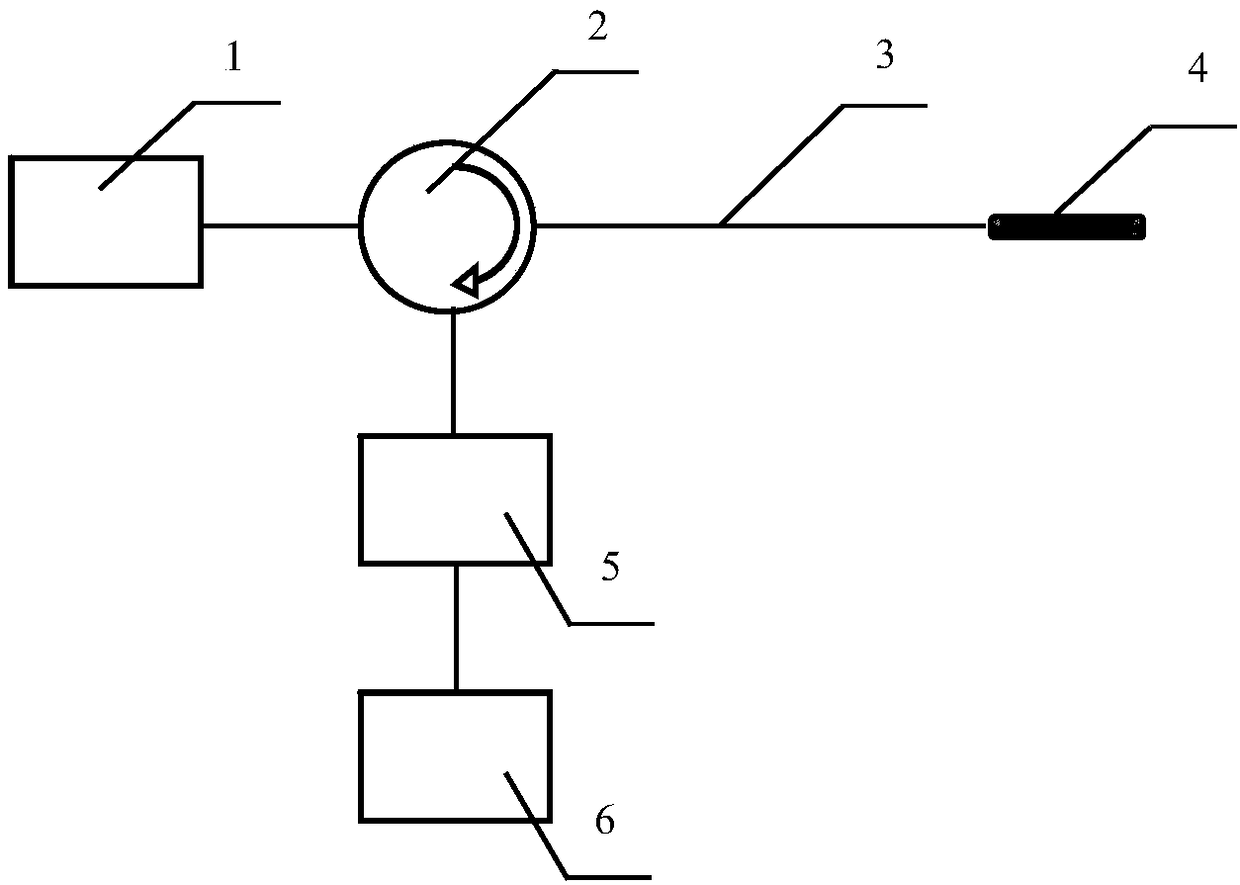

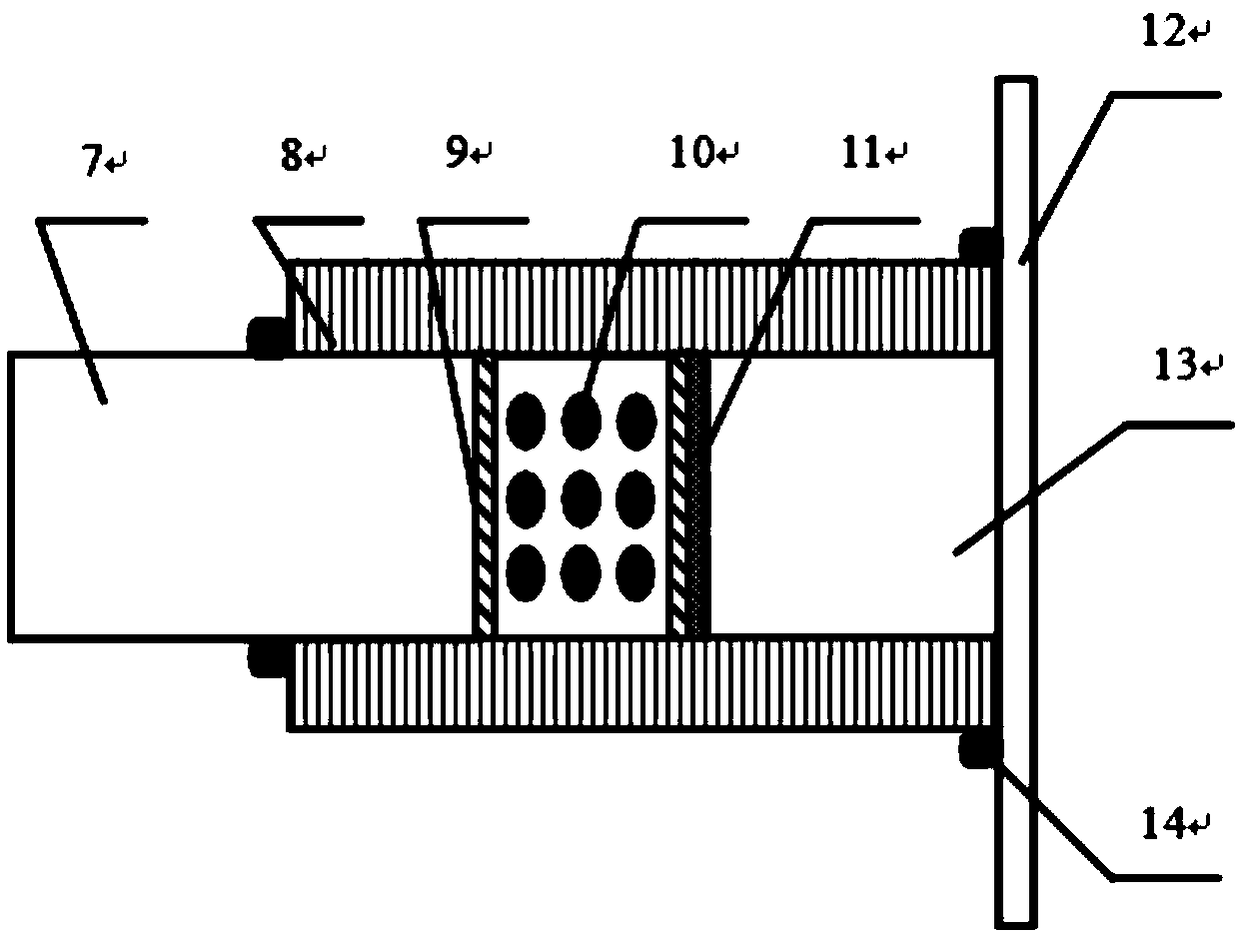

[0027] The present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments.

[0028] A kind of optical fiber hydrophone based on the liquid crystal Fabry-Perot resonator of the present invention and preparation method thereof, comprise: design liquid crystal 10 to be filled between the end faces of two optical fibers, use the polydimethylsiloxane of making (PDMS) sleeve 8 and epoxy glue 14 for encapsulation. One of the optical fibers is coated with a high-reflection film, thereby forming a Fabry-Perot cavity on the end faces of the two optical fibers, and both end faces of the two optical fibers are subjected to light-controlled orientation treatment. The acoustic vibration signal is pressed onto the PDMS sleeve 8 through the polymethyl methacrylate (PMMA) sheet on the rear end surface of the reflective fiber, and the sleeve 8 is deformed laterally under the pressure, so that the length of the Fabry-Perot cavit...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Length | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap