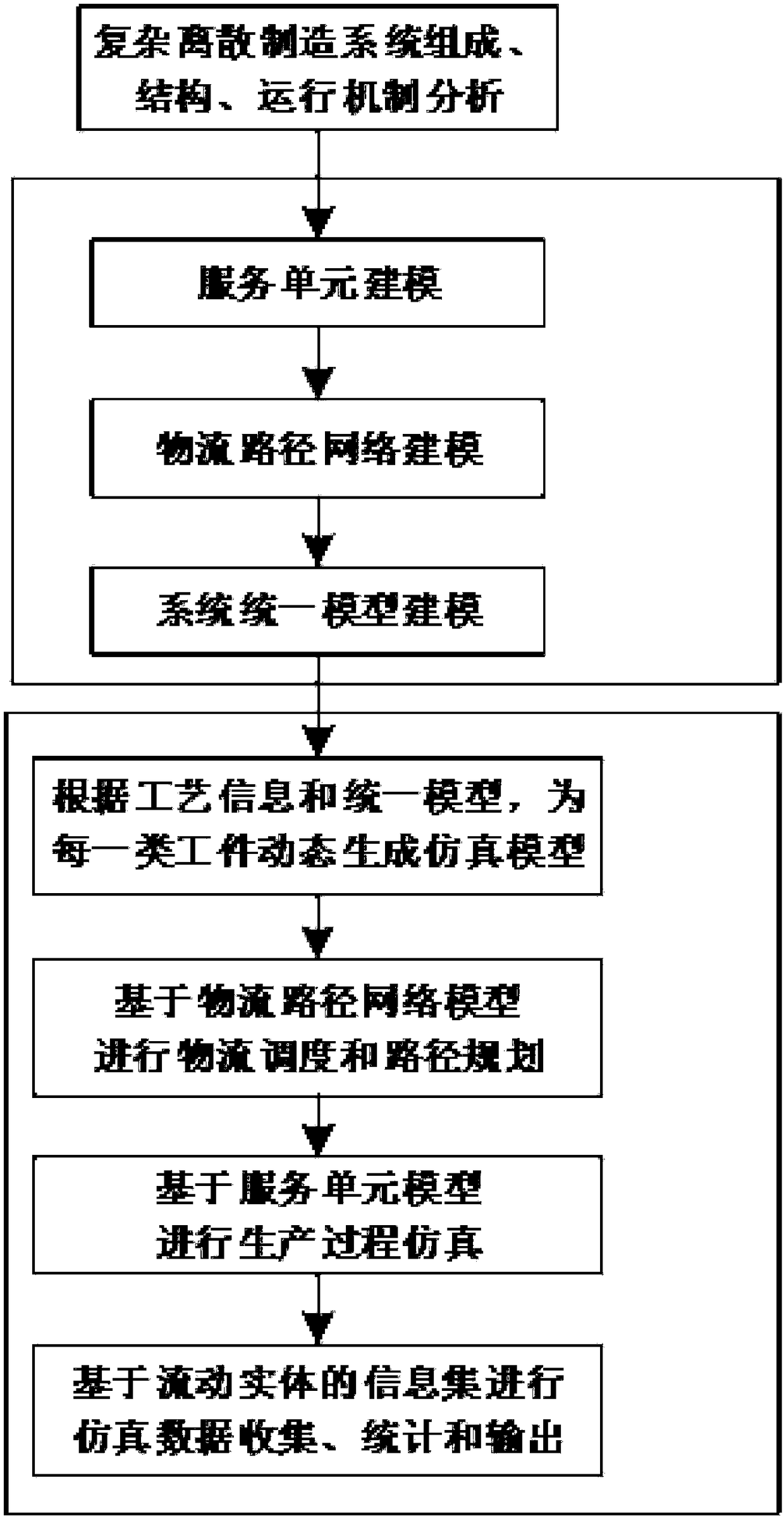

Unified modeling method and simulation method for multiple virtual service nodes

A virtual service and node technology, applied in control/regulation systems, simulators, general control systems, etc., can solve the problem of reducing system complexity, lack of strict graphics and algebraic definitions, difficult to deal with flexible manufacturing systems and reconfigurable manufacturing system problems

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0034] The present invention will be further described below through the accompanying drawings and specific embodiments.

[0035] The terms used in this article are explained as follows:

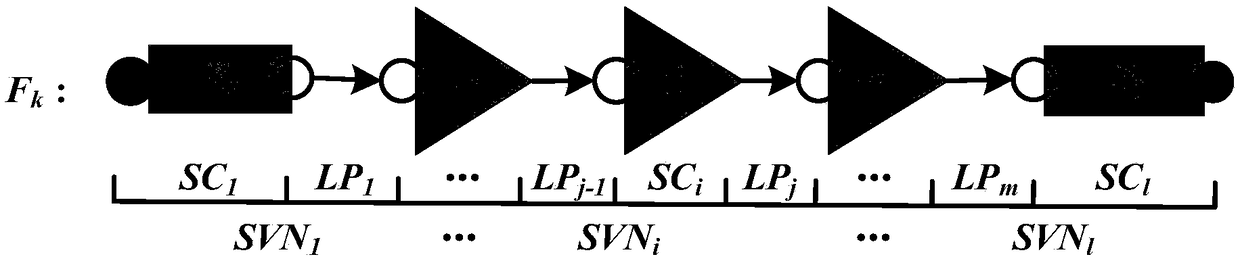

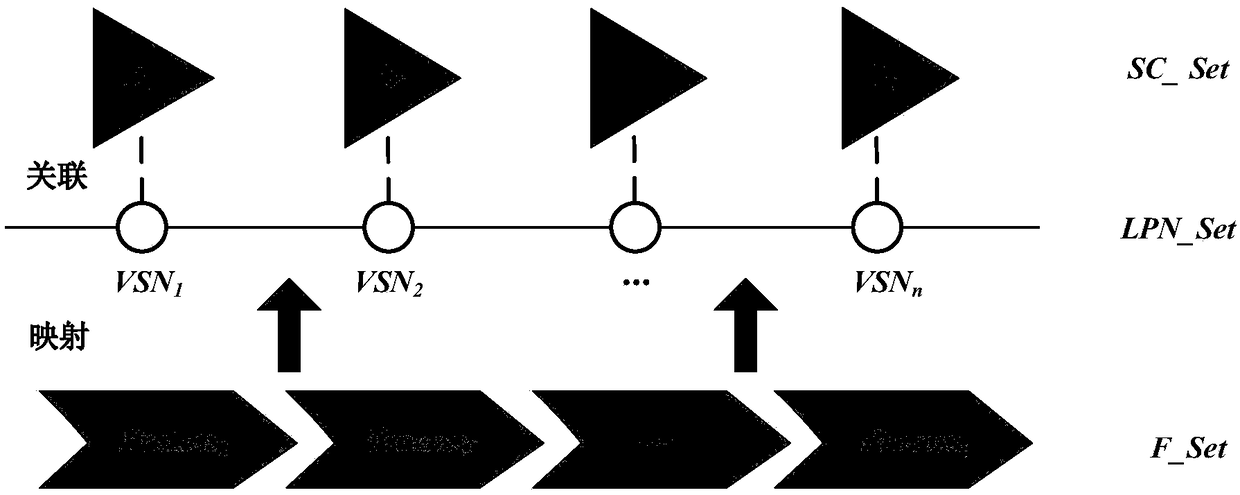

[0036] Virtual Service Node (VSN) is a high-level abstraction and mapping of complex system production organization relations, logistics control logic, and production procedures; its main connotations include the following three:

[0037] (1) The virtual service node is the abstraction and mapping of the production organization relationship; VSN associates a group of objects related to a specific service to form a service cell (Service Cell, SC), and defines the composition of the service cell, service content and external communication. Interface; through the virtual service node, you can traverse to each component of the service unit and obtain information such as the location and status of related objects.

[0038] (2) The virtual service node is the abstraction and mapping of logistics ...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap