Intelligent balancing lever compensation method and balancing lever machining process using same

A compensation method and processing technology, applied in the field of auto parts processing, can solve problems such as the inability to output the parameters of the end hole of the balance rod in time, the inability to accurately adjust the processing technology in time, the influence of processing accuracy and efficiency, etc., so as to improve the purchasing experience and avoid Large batches of substandard products or scrap, the effect of improving processing accuracy and efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

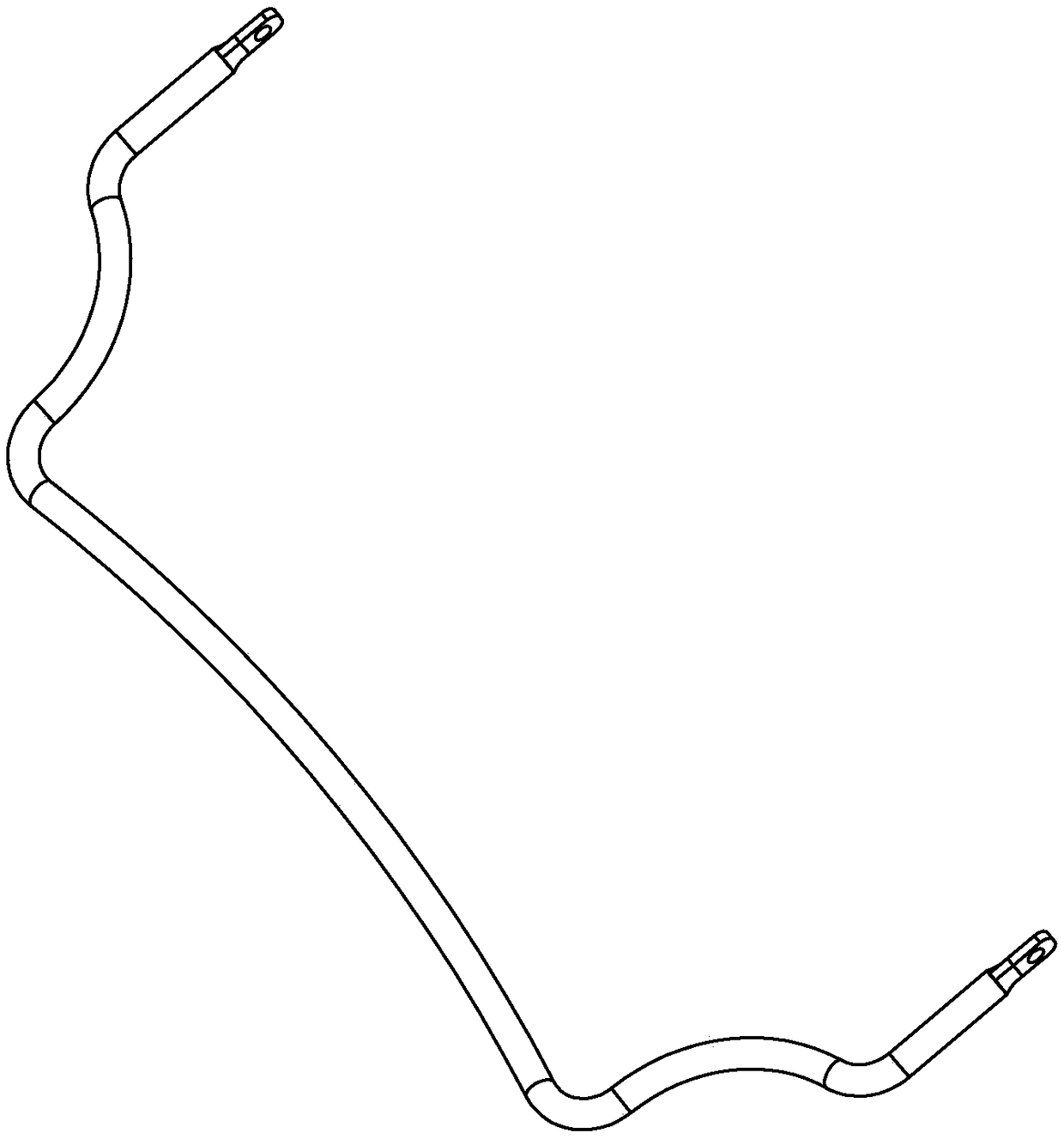

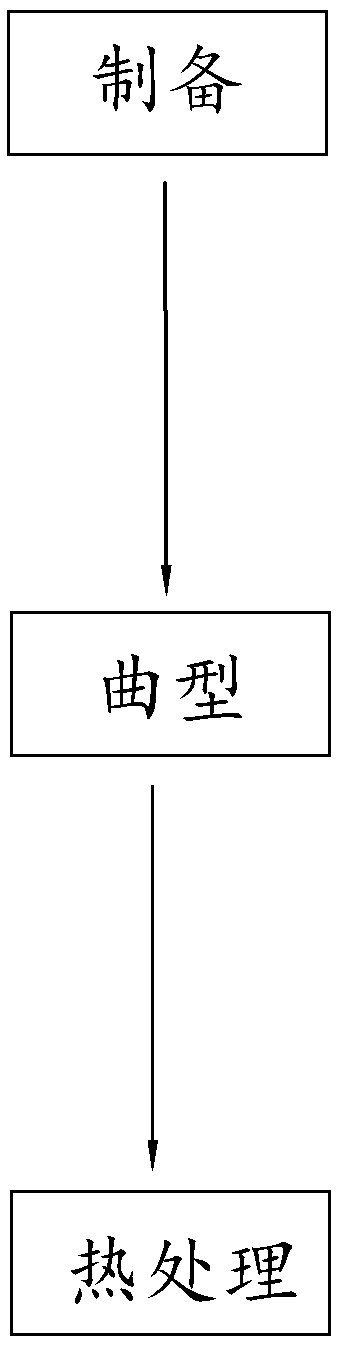

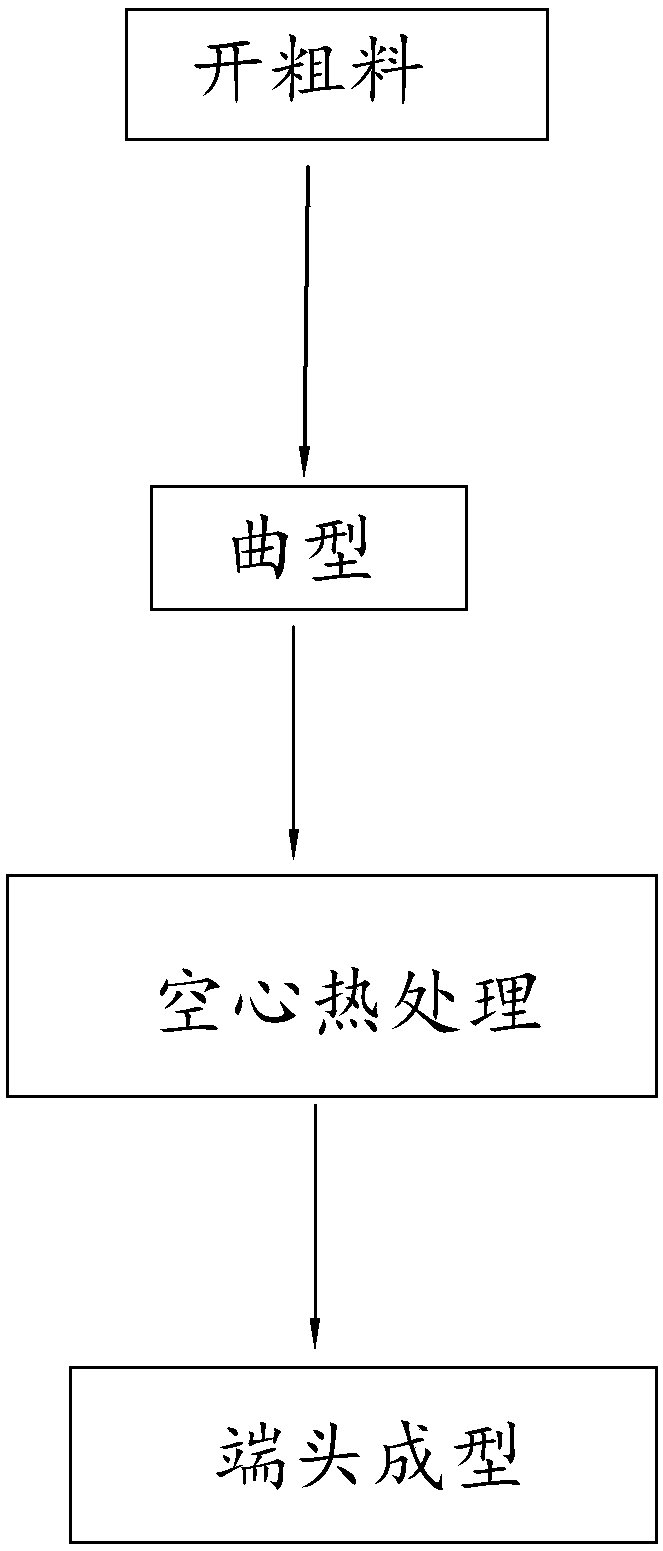

[0059] Embodiment 1, the balance bar intelligent compensation method and the balance bar processing technology using the method, the balance bar processing technology can be divided into: solid balance bar process and hollow balance bar process according to the different types of balance bar processed, and the forming stages of the two are respectively according to The following operations, such as figure 2 with image 3 shown.

[0060] The forming process of solid balance bar includes:

[0061] a1. Preparation, including processing the columnar balance bar rough material by sawing machine, punching machine and other cutting equipment, using heating equipment, generally an intermediate frequency furnace to heat the balance bar rough material, and using an upset forging machine to make the end of the heated balance bar rough material Flattening, trimming, punching, and controlling the total length to prepare the primary material of the balance bar;

[0062] a2. Curved shape...

Embodiment 2

[0102] Embodiment 2, apply the balance bar processing technology of the balance bar intelligent compensation method, refer to Figure 5 with Image 6 ,include:

[0103] A1. Forming, setting and processing the balance bar according to the processing method of the balance bar; the processing method of the balance bar has certain differences according to whether the processed balance bar is hollow or solid, and the operation can be carried out according to the content of the first embodiment.

[0104] A2. Process parameter correction. The numerical control mechanism 2 obtains the end hole position parameters through the feedback mechanism 1, and controls the balance bar processing equipment to correct the processing action according to the balance bar intelligent compensation method. For details, refer to Embodiment 1. The types of balance bars processed are different, and the feedback The installation position of mechanism 1 and the position of collecting information are differ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com