Energy-saving auxiliary manual pineapple picking machine

A picking machine, energy-saving technology, applied in the direction of renewable energy machines, harvesters, agricultural machinery and equipment, etc., can solve the problems of low picking efficiency, hidden safety hazards, large labor load, etc., to ensure picking quality, stable operation, and saving. energy effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] The above description is only an overview of the technical solution of the present invention. In order to understand the technical means of the present invention more clearly and implement it according to the description, the preferred embodiments of the present invention will be described in detail below with accompanying drawings.

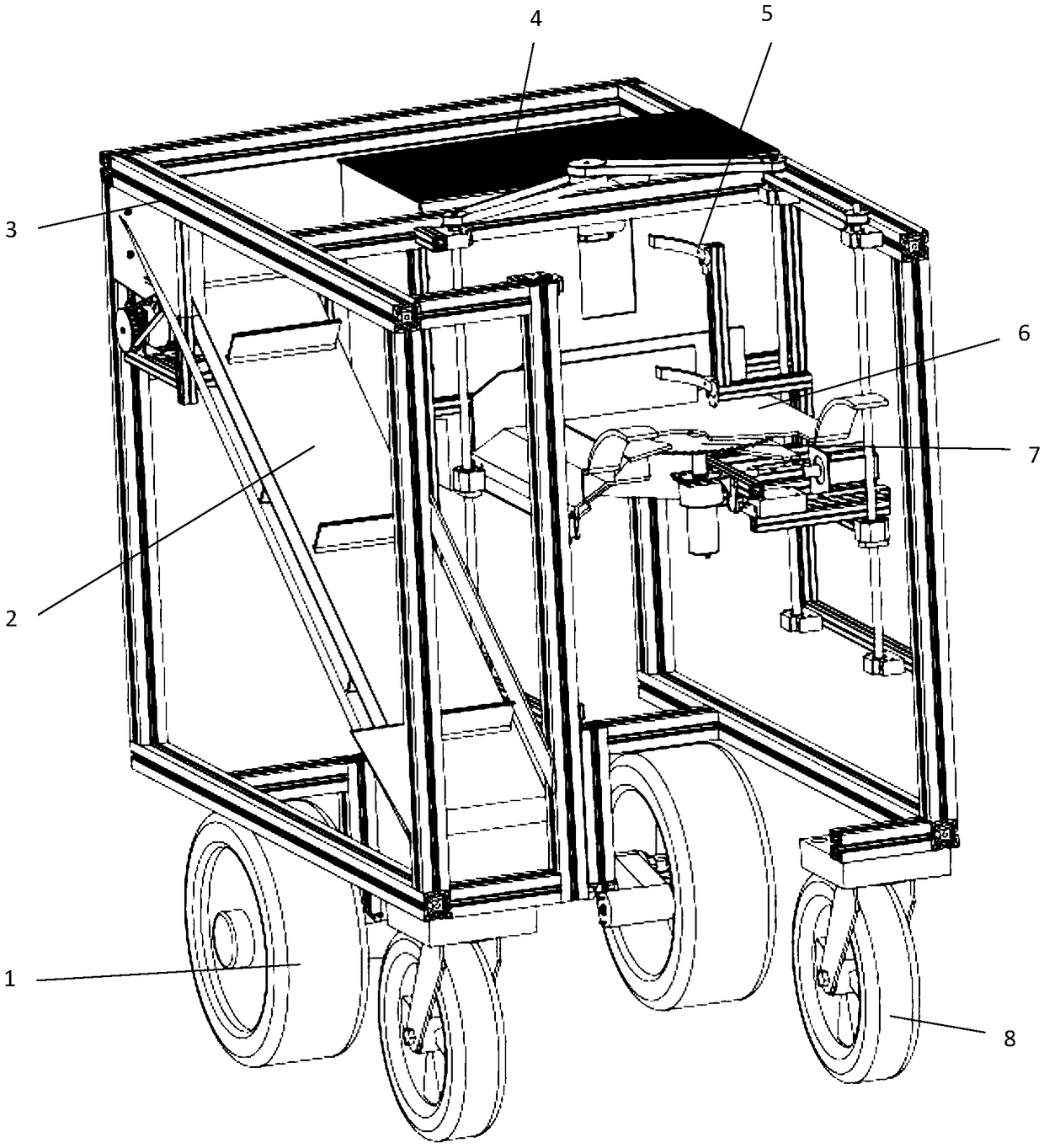

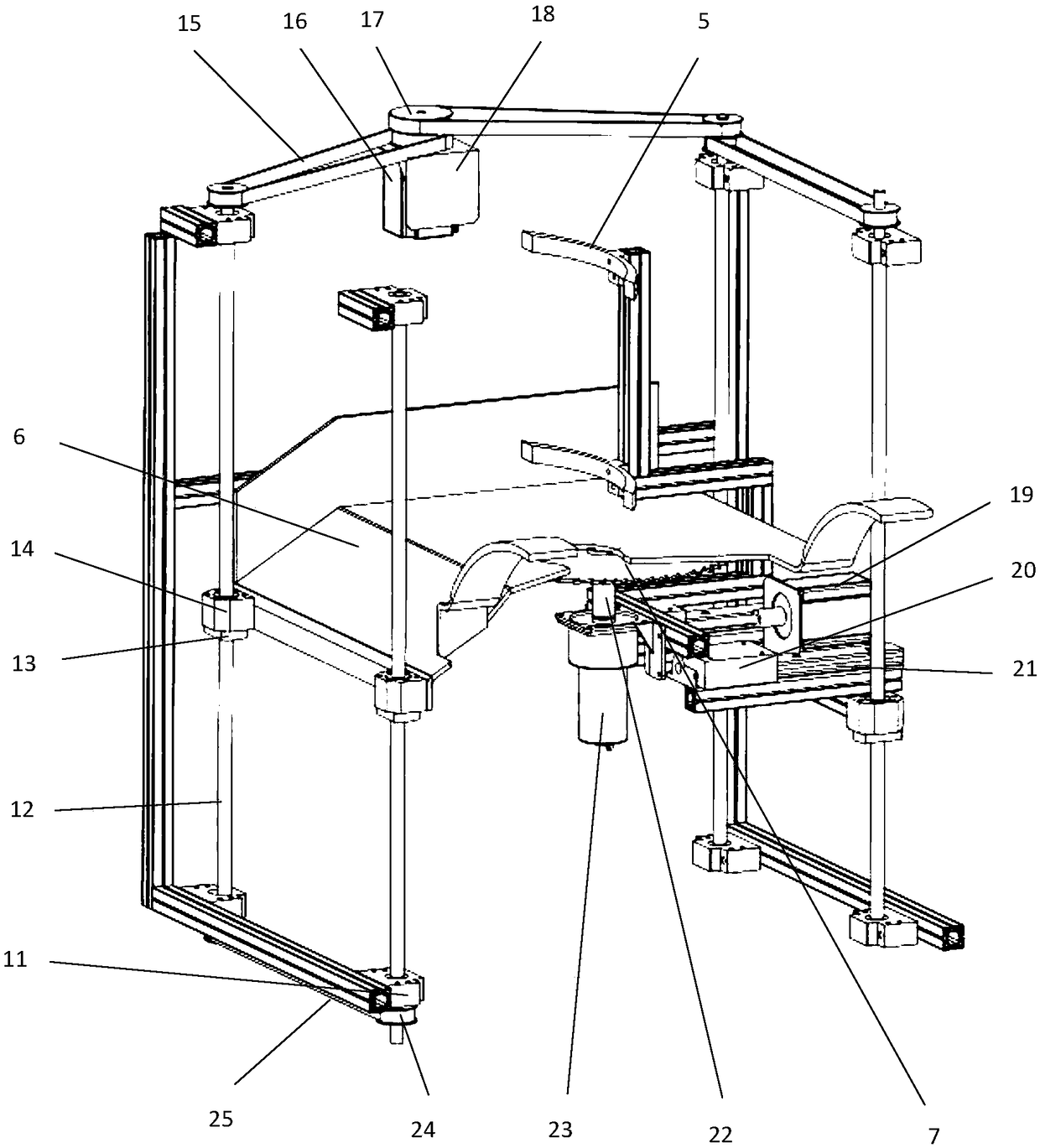

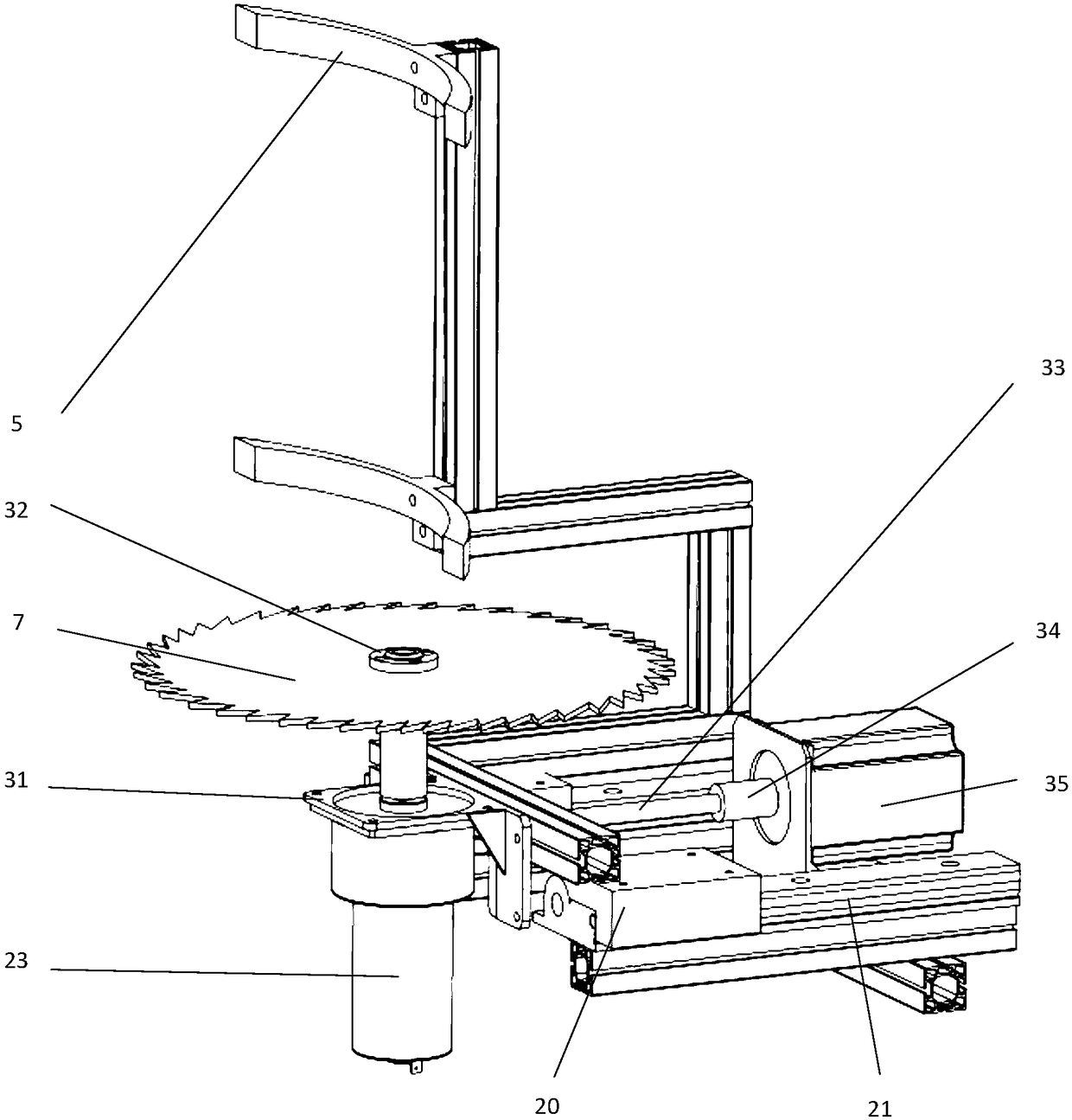

[0031] The energy-saving auxiliary artificial pineapple picking machine of the present invention can realize the function of assisting manual picking pineapples, such as figure 1 , Figure 4 As shown, it includes picking parts, collecting parts, power transmission parts, supporting parts, and solar power generation modules. Such as figure 2 As shown, the picking part consists of a picking platform (6), a picking saw blade (7) for cutting, a double guide rail slider mechanism (20, 21), a four-screw linkage mechanism (12, 13), and a Composed of a thrust fork (5) and a two-stage belt drive (15, 25), the picking platform is a 2mm thick alum...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com