Fermentation system of microorganism fermentation feed

A microbial fermentation and fermentation system technology, applied in the field of fermented feed production equipment, can solve the problems of inability to mix materials in fermentation tanks, difficulty in controlling temperature and humidity, and high labor intensity of workers, so as to avoid submerged deterioration, solve low efficiency, and solve laborious digging Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] The present invention will be further described in detail below in conjunction with the accompanying drawings, so that those skilled in the art can implement it with reference to the description.

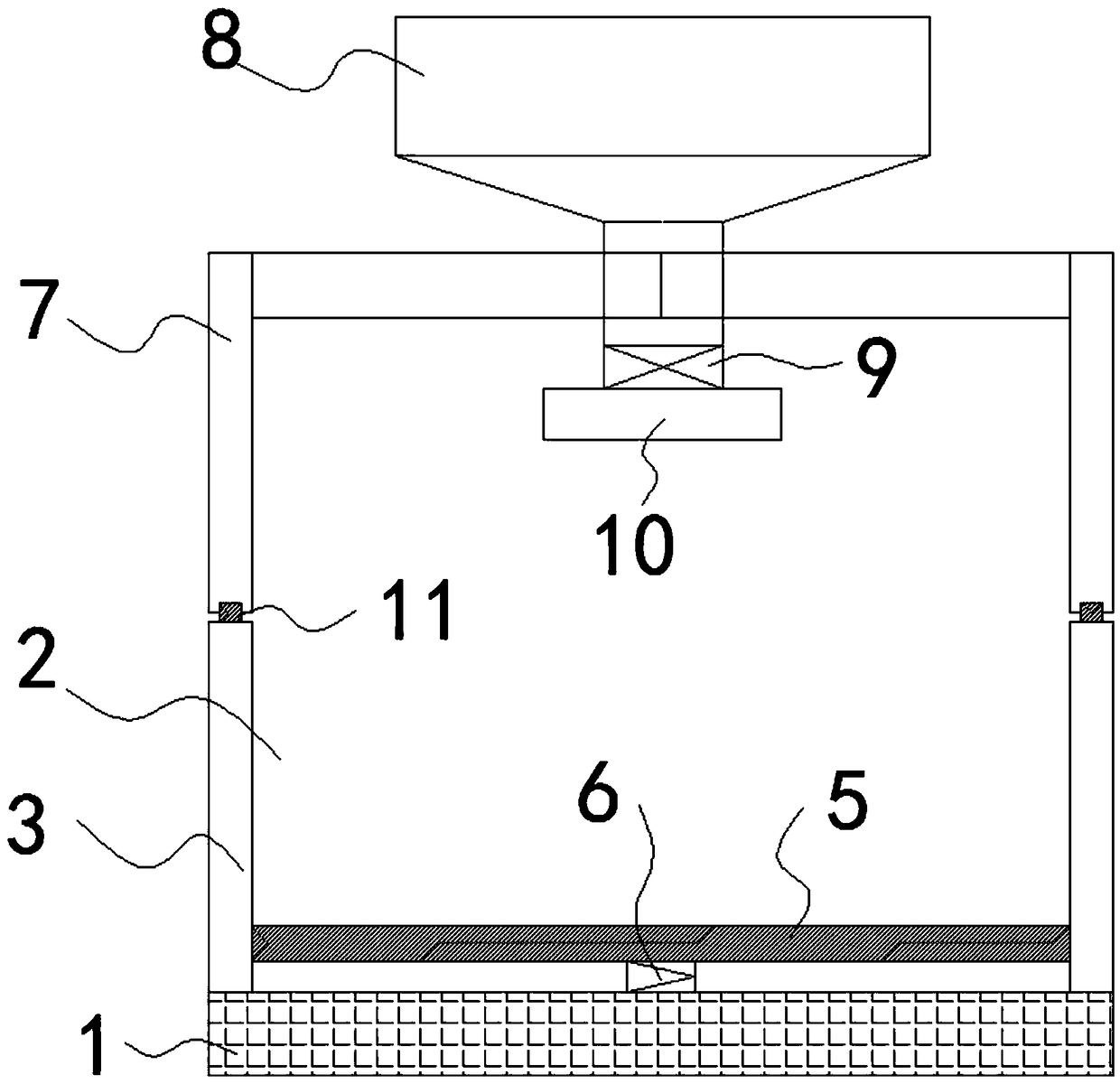

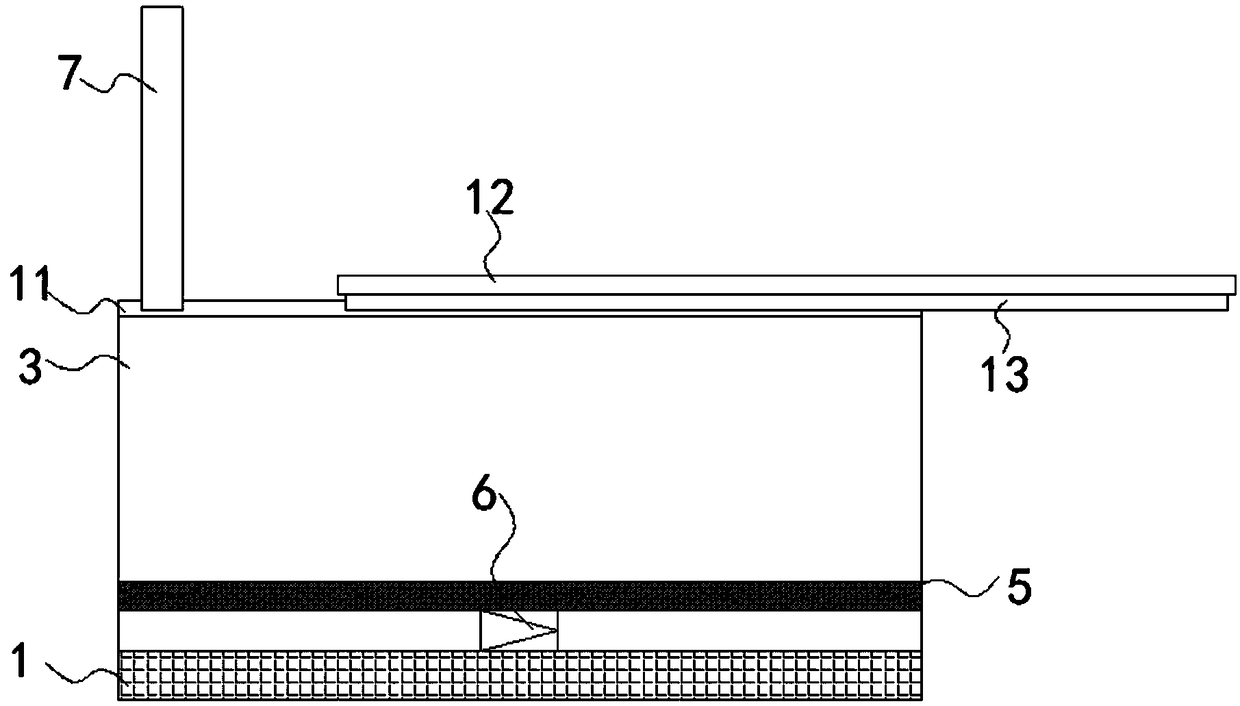

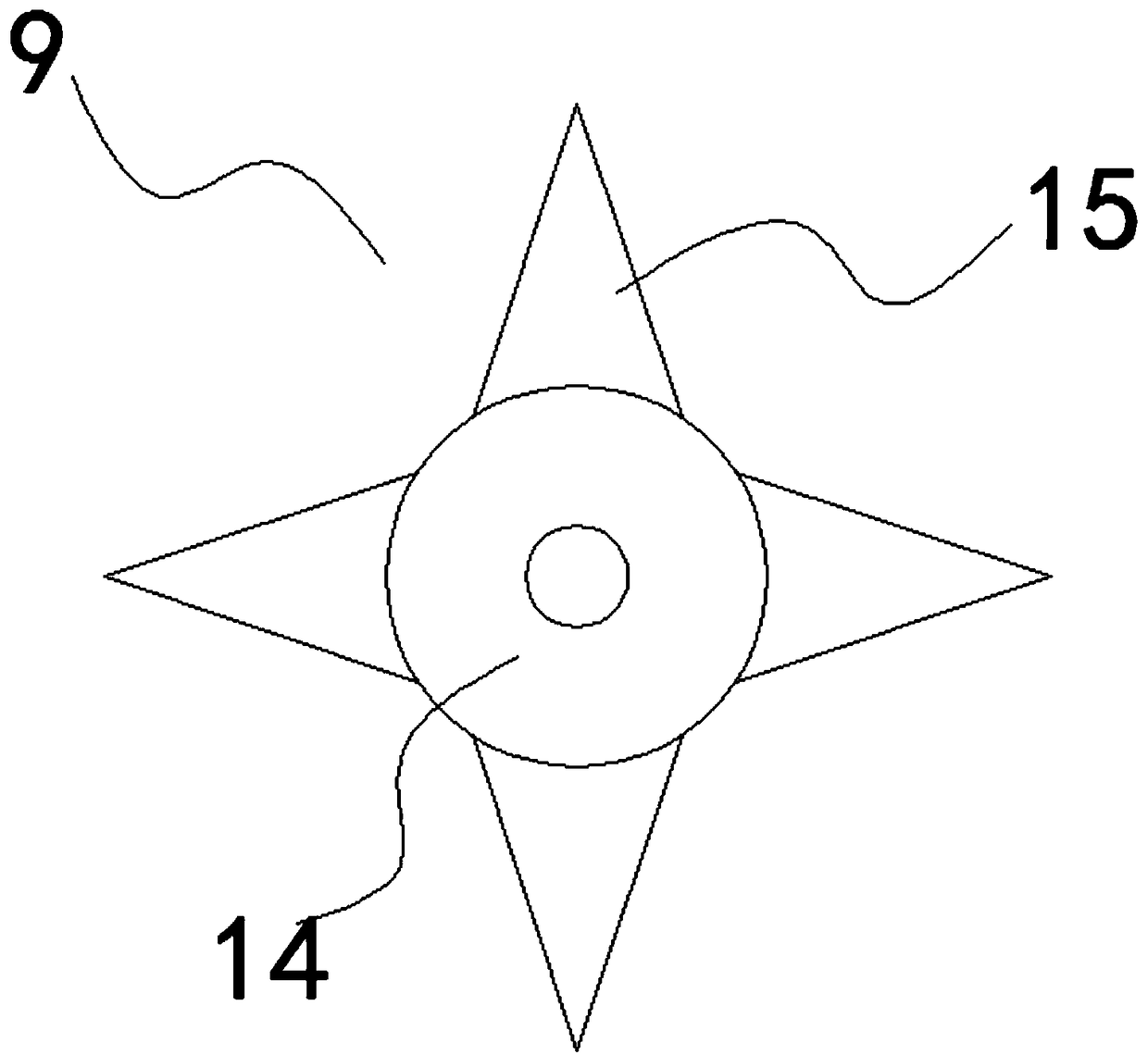

[0034] Such as figure 1 , 2 , 3, 4 and 5, a microbial fermentation feed fermentation system, comprising:

[0035] Foundation 1, which is arranged on the ground; in order to build a fermentation tank 2 on the foundation 1; the upper surface of the foundation 1 is laid with a tile layer formed by a combination of multiple tiles, and the tile layer has a waterproof effect and can prevent liquid from going down Penetration, while the tile layer also makes the bottom of the fermentation tank easier to clean.

[0036] A rectangular fermentation tank 2 surrounded by two short walls and two long walls 3, the fermentation tank 2 is located on the foundation 1, and the upper surface of the foundation 1 is the bottom of the fermentation tank 2, the A track 11 is arranged on the top o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com