Cyclone and bag dust collection integrated device

A technology of bag dust removal and cyclone dust collector, which is applied in the direction of combined devices, chemical instruments and methods, and separation of dispersed particles. Field distribution, the effect of ensuring dust removal efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

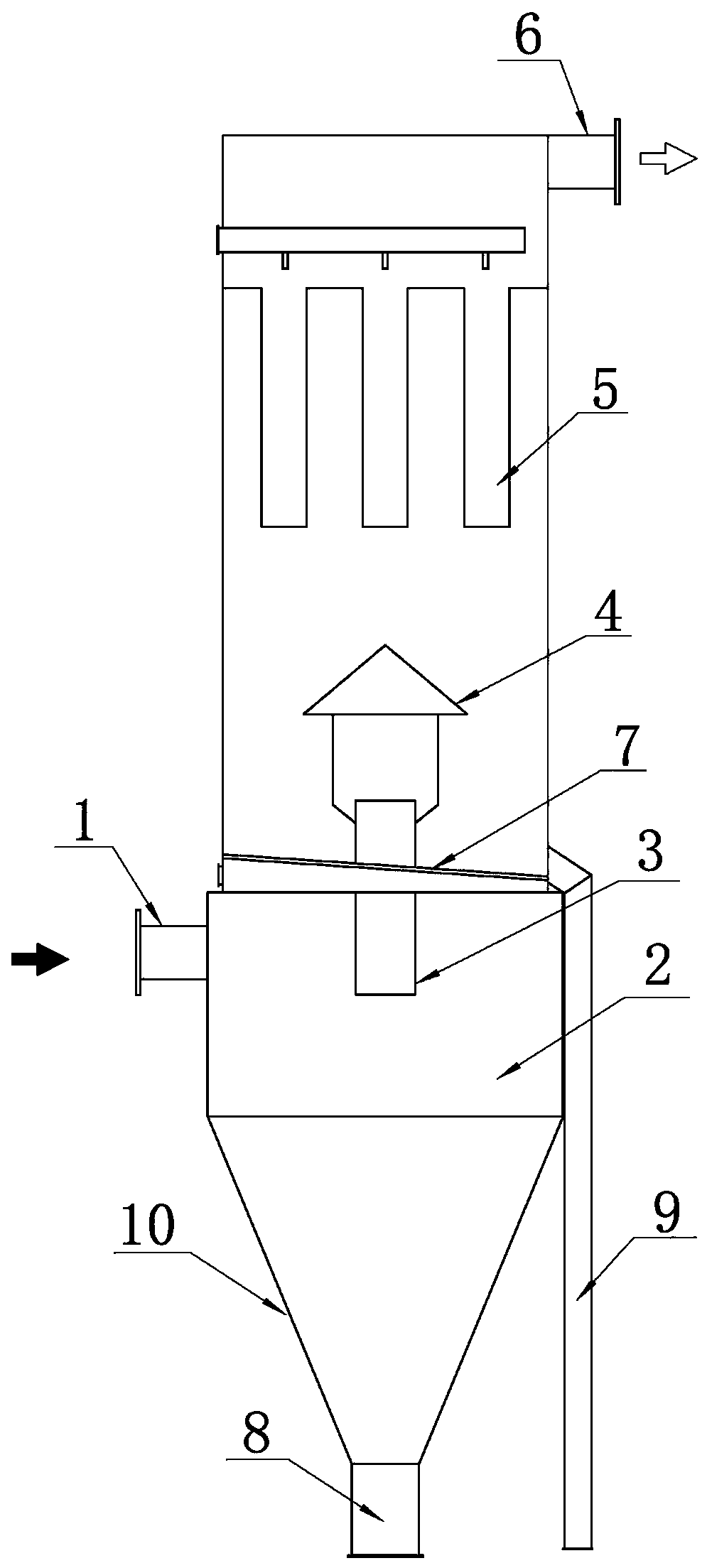

[0013] To make the above-mentioned purposes, features and advantages of the present invention more obvious and understandable, below in conjunction with the attached figure 1 The present invention will be further described in detail with specific embodiments.

[0014] The cyclone bag dust removal integrated device adopted in this embodiment includes a cyclone dust collector 2 and a pulse cleaning bag filter 5, the cyclone dust collector 2 and the pulse cleaning bag filter 5 are integrally formed, and the pulse cleaning bag filter 5 is located above the cyclone dust collector 2. The bottom of the cyclone dust collector 5 is used as the ash storehouse 10, and the ash storehouse 10 communicates with the coarse dust discharge port 8, which is convenient for dust recycling. An umbrella-shaped airflow cover 4 is arranged above the flue gas outlet 3 in the cyclone dust collector 2. After the smoke particles with sparks collide with the umbrella-shaped airflow cover 4, the sparks ent...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com