A kind of extruding die and method of corner expanding diameter by using bar material to prepare pipe

An extrusion die and corner technology, which is applied in the field of corner expansion extrusion die, can solve the problems of lack of diversion, inconvenient removal of parts, low deformation load, etc. Variety of deformation modes

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

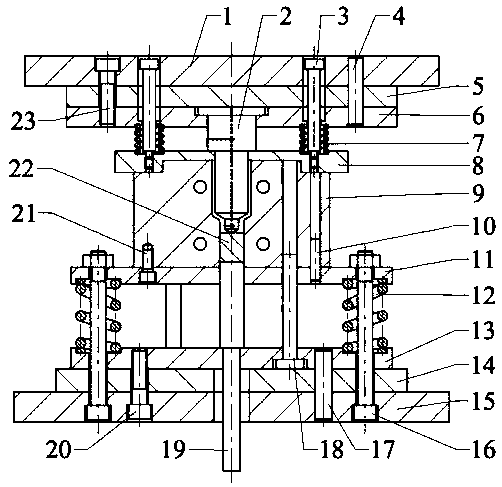

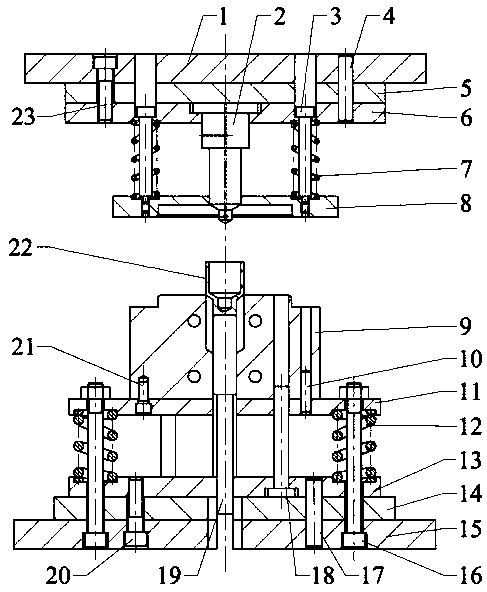

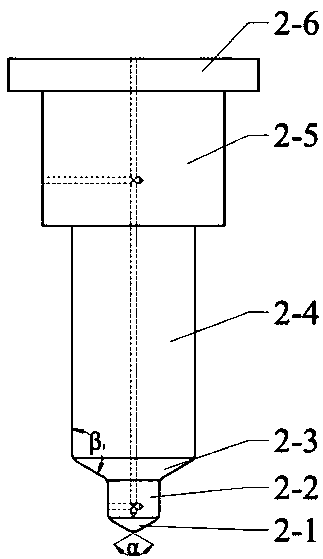

[0041] Example: such as Figure 1 to Figure 10 As shown in the figure, a corner-expanding extrusion die for preparing pipes from bar stock includes an upper template 1, an extrusion mandrel 2, an upper backing plate 5, a mandrel fixing plate 6, a stripping plate 8, a die 9, a die Die support plate 11, punch support plate 13, backing plate 14, lower template 15, inner guide post 18, extrusion punch 19; upper template 1 is fixed on the press slide block, extrusion mandrel 2 is stepped, There is a stepped circular hole in the center of the mandrel fixing plate 6, and the extruding mandrel 2 is installed in the round hole of the mandrel fixing plate 6, and the upper backing plate 5 is placed on the mandrel fixing plate 6, and the extruding mandrel 2, upper The backing plate 5 and the mandrel fixing plate 6 are fixed on the upper formwork 1 through the pin 3 4 and the inner hexagonal bolt 1 23; In the center hole, a discharge bolt 3 is installed on the upper end of the discharge p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com