Grinding method for non-circular curved glass ornaments based on point cloud data description

A technology of curved glass and point cloud data, which is applied in the field of grinding of non-circular curved glass ornaments based on point cloud data description, can solve the problems of heavy workload, heavy calculation, cumbersome drawing, etc., and achieve small error and smooth grinding High precision, overcome the cumbersome effect of drawing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] The present invention is described below in conjunction with accompanying drawing.

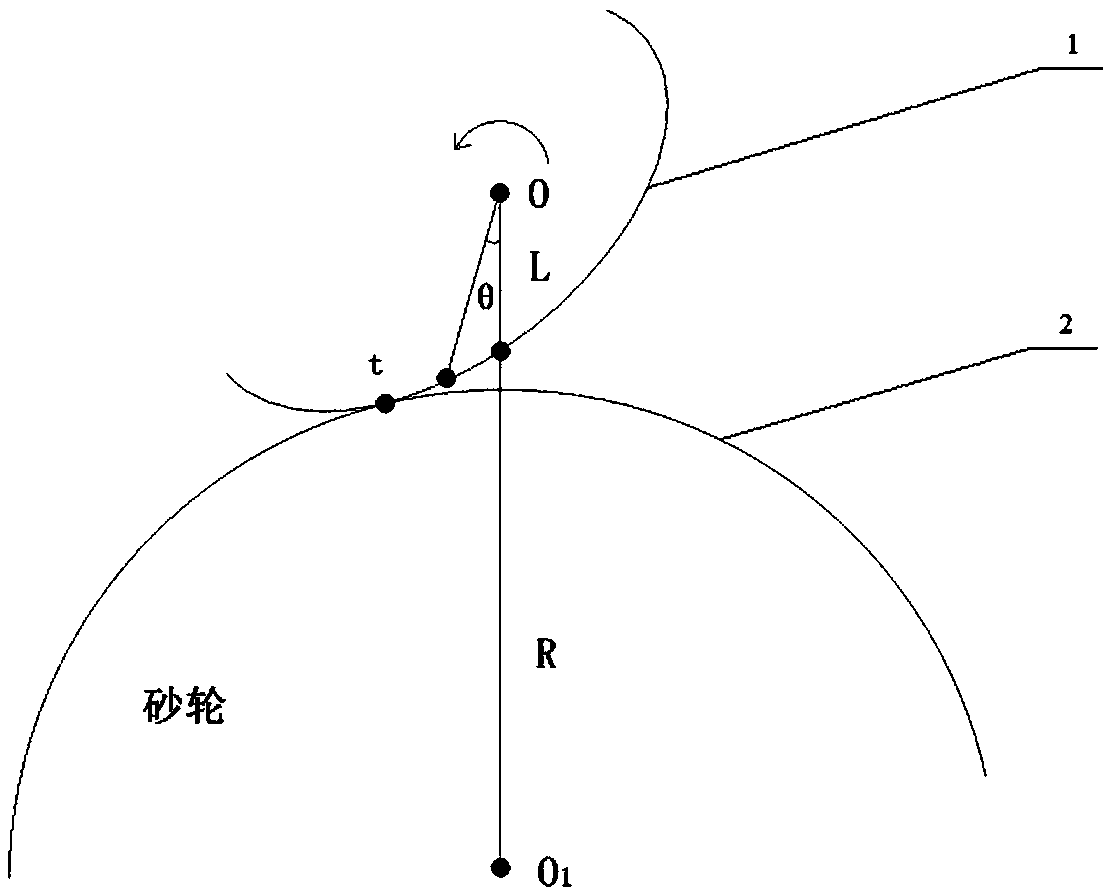

[0030] Such as figure 1 As shown, a non-circular curved glass jewelry grinding method based on point cloud data is used to process any non-circular curved glass workpiece. The number 1 in the figure is the non-circular curved glass workpiece, 2 is the grinding wheel, and O is the center of the workpiece , O 1 is the center of the grinding wheel.

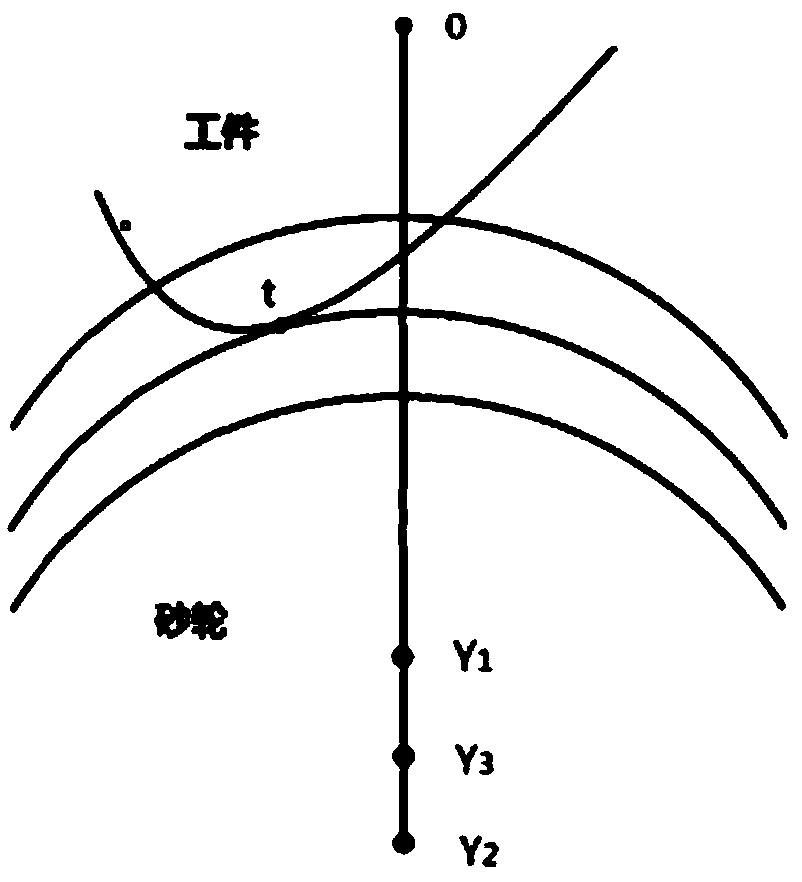

[0031] Step 1: Determine the linkage data for controlling the C-axis movement of the workpiece rotation and the Y-axis for longitudinal tracking feed. Specific steps are as follows:

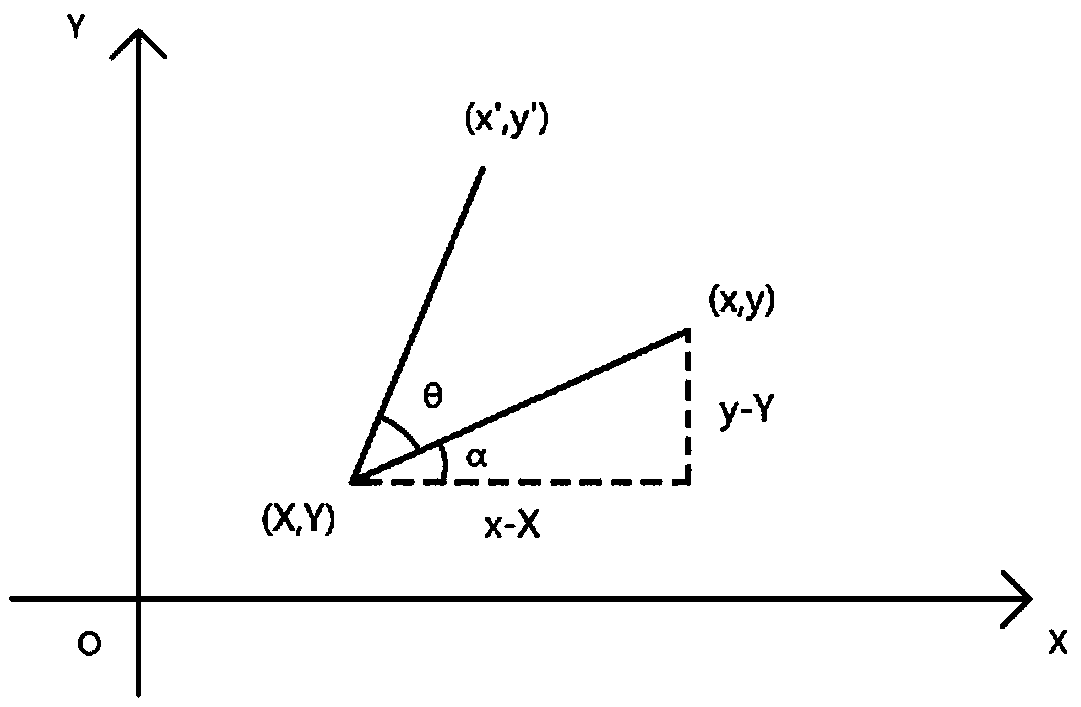

[0032] (1) The equation of the outer circle of the known grinding wheel is: (x-X)^2+(y-Y’)^2=R^2, where: (X, Y’) is the center of the grinding wheel O 1coordinates, R is the radius of the grinding wheel; store the coordinate point data describing the contour of the workpiece in the array Array1, and store the coordinates of the first coordinate point at the e...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com