A high-efficiency energy-absorbing fiber-metal composite pipe and a mold-free preparation method thereof

A technology of fiber metal and composite pipes, which is applied in the field of high-efficiency energy-absorbing fiber-metal composite pipes and its moldless preparation, can solve problems such as stress concentration, interfacial pores, and performance effects of composite components, achieve high energy absorption efficiency, and reduce production cost, effect of alleviating urgent needs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

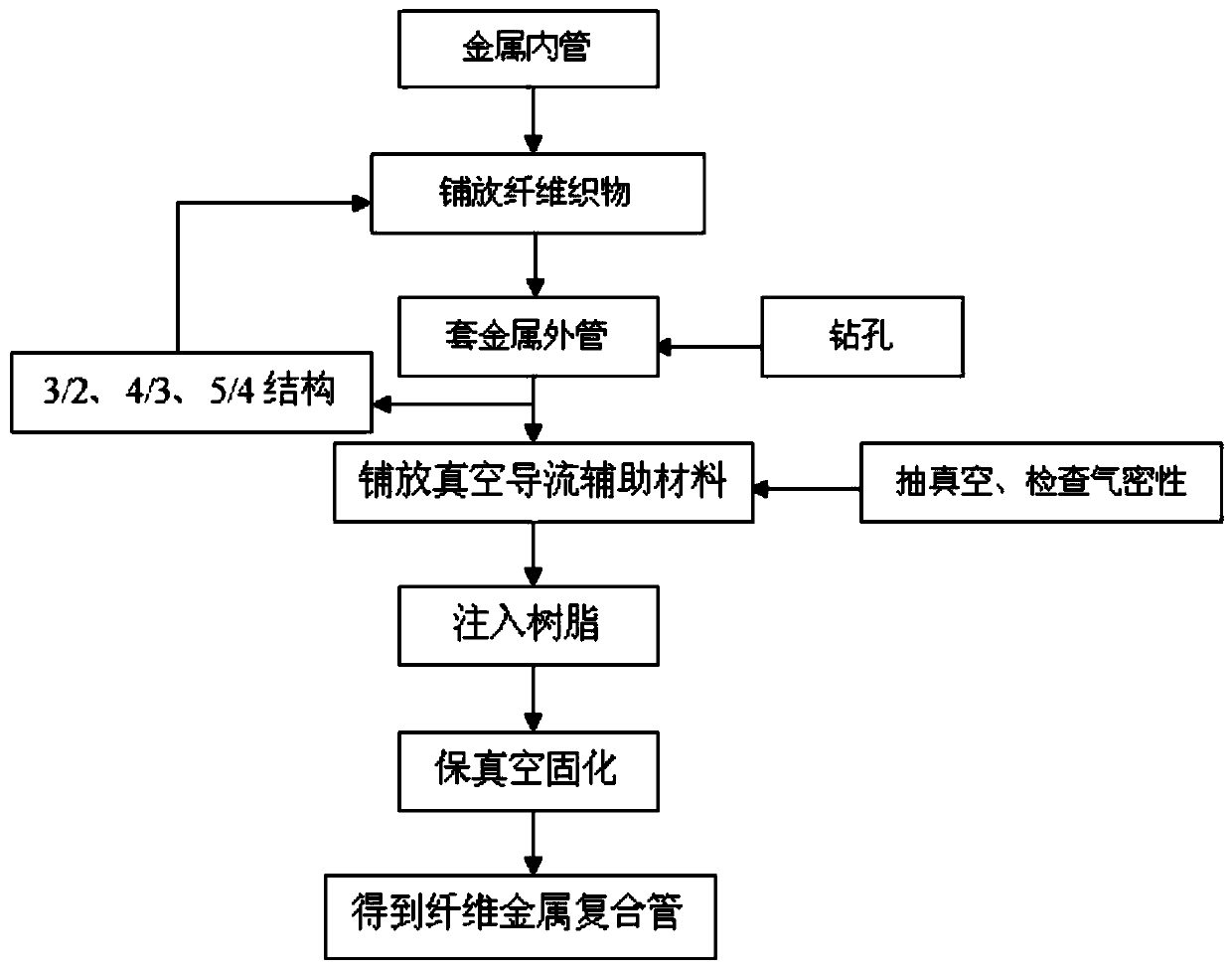

Method used

Image

Examples

Embodiment 1

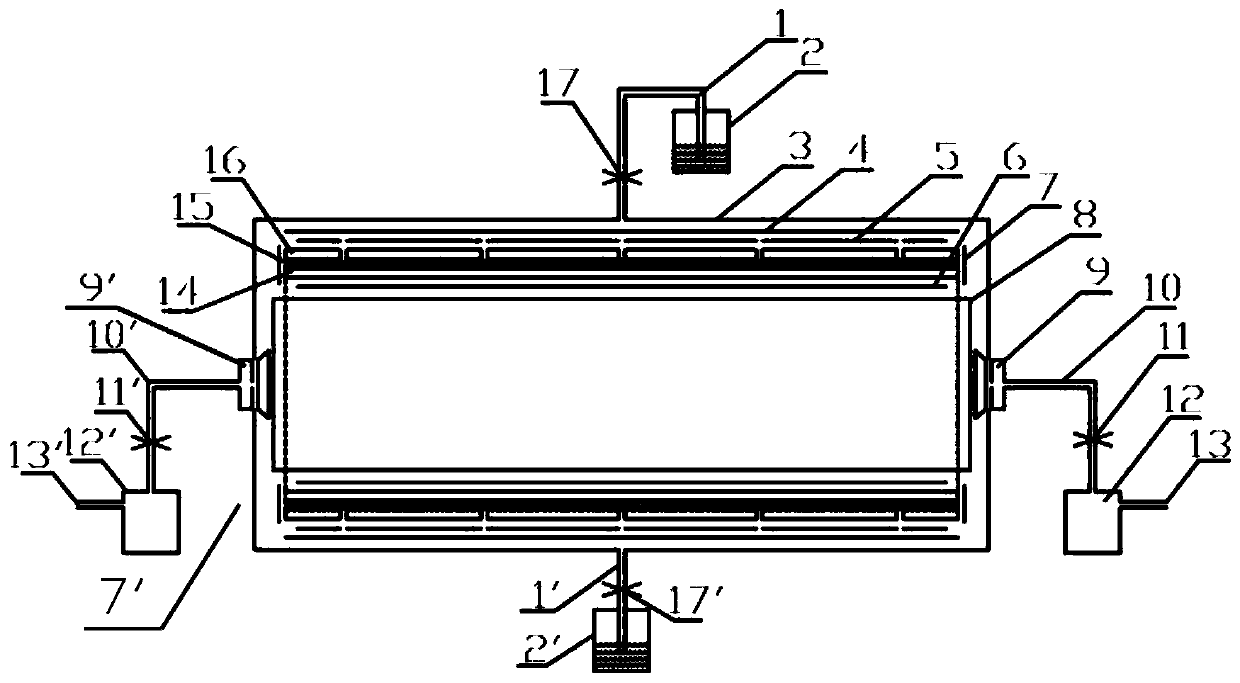

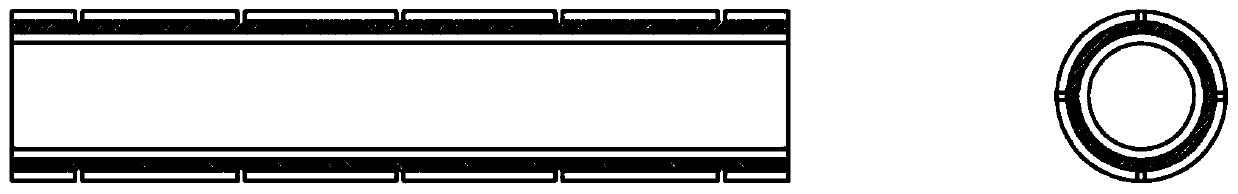

[0033] In the first step, a 6061 aluminum alloy round tube with an outer diameter of 38 mm and an inner diameter of 35 mm and a length of 300 mm is selected as the inner tube, and its surface is treated by phosphoric acid anodizing. Cut a unidirectional glass fiber woven cloth with a length of 600 mm and a width of 300 mm (spread 5 layers), pretreatment: extract with acetone as a solvent in a Soxhlet extractor for 48 hours, dry at 105°C for 1 hour, activation treatment: first immerse in 80°C HC1:H 2 o 2 :H 2 O=1:1:5 solution for 5min, rinsed with distilled water several times, in 80°C NH 3 :H 2 o 2 :H 2 O=1:1:5 solution was treated for 5 minutes, finally treated with 0.5% silane coupling agent / ethanol solution for 30 minutes, and dried at 105°C. Wrap the pretreated and activated unidirectional glass fiber woven cloth on the aluminum tube (the 0° direction is parallel to the axis direction of the aluminum tube);

[0034] The second step is to select a 6061 aluminum alloy...

Embodiment 2

[0040] The first step is to select a 6061 aluminum alloy round tube with a small head outer diameter of 30mm and an inner diameter of 27mm, a large head with an outer diameter of 58mm and an inner diameter of 55mm and a length of 300mm as the inner tube, and perform surface treatment by phosphoric acid anodizing. Cut out a unidirectional glass fiber woven cloth with an isosceles trapezoidal shape of 95mm in length, 185mm in length at the bottom, and 300mm in height (4 layers), pretreatment: extract with acetone as a solvent in a Soxhlet extractor for 48 hours, and dry at 105°C After 1h, activation treatment: first immerse in HC1:H at 80°C 2 o 2 :H 2 O=1:1:5 solution for 5min, rinsed with distilled water several times, in 80°C NH 3 :H 2 o 2 :H 2 O=1:1:5 solution was treated for 5 minutes, finally treated with 0.5% silane coupling agent / ethanol solution for 30 minutes, and dried at 105°C. Wrap the pretreated and activated unidirectional glass fiber woven cloth on the alumi...

Embodiment 3

[0047] In the first step, a TA2 titanium alloy square tube with an outer diameter of 46 mm, a thickness of 1 mm and a length of 200 mm is selected as the first layer of metal tube, and the surface is treated by acetone ultrasonic cleaning. Cut a biaxial carbon fiber woven cloth with a length of 1500mm and a width of 200mm (spread 8 layers) as the first fiber layer, pretreatment: extract with acetone as a solvent in a Soxhlet extractor for 48 hours, and dry at 105°C for 1 hour. Activation treatment: first immerse in HC1:H at 80°C 2 o 2 :H 2 O=1:1:5 solution for 5min, rinsed with distilled water several times, in 80°C NH 3 :H 2 o 2 :H 2 O=1:1:5 solution was treated for 5 minutes, finally treated with 0.5% silane coupling agent / ethanol solution for 30 minutes, and dried at 105°C. Wrap the pretreated and activated biaxial carbon fiber woven cloth on the titanium tube;

[0048] In the second step, a TA2 titanium alloy square tube with an outer diameter of 48 mm, a thickness ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com