Efficient energy absorption fiber and metal composite pipe and mold-free preparation method thereof

A fiber metal and composite pipe technology, which is applied in the field of high-efficiency energy-absorbing fiber-metal composite pipe and its mold-free preparation, can solve problems such as interface porosity, impact on the performance of composite components, stress concentration, etc., so as to reduce production costs and alleviate urgent needs. , the effect of high energy absorption efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

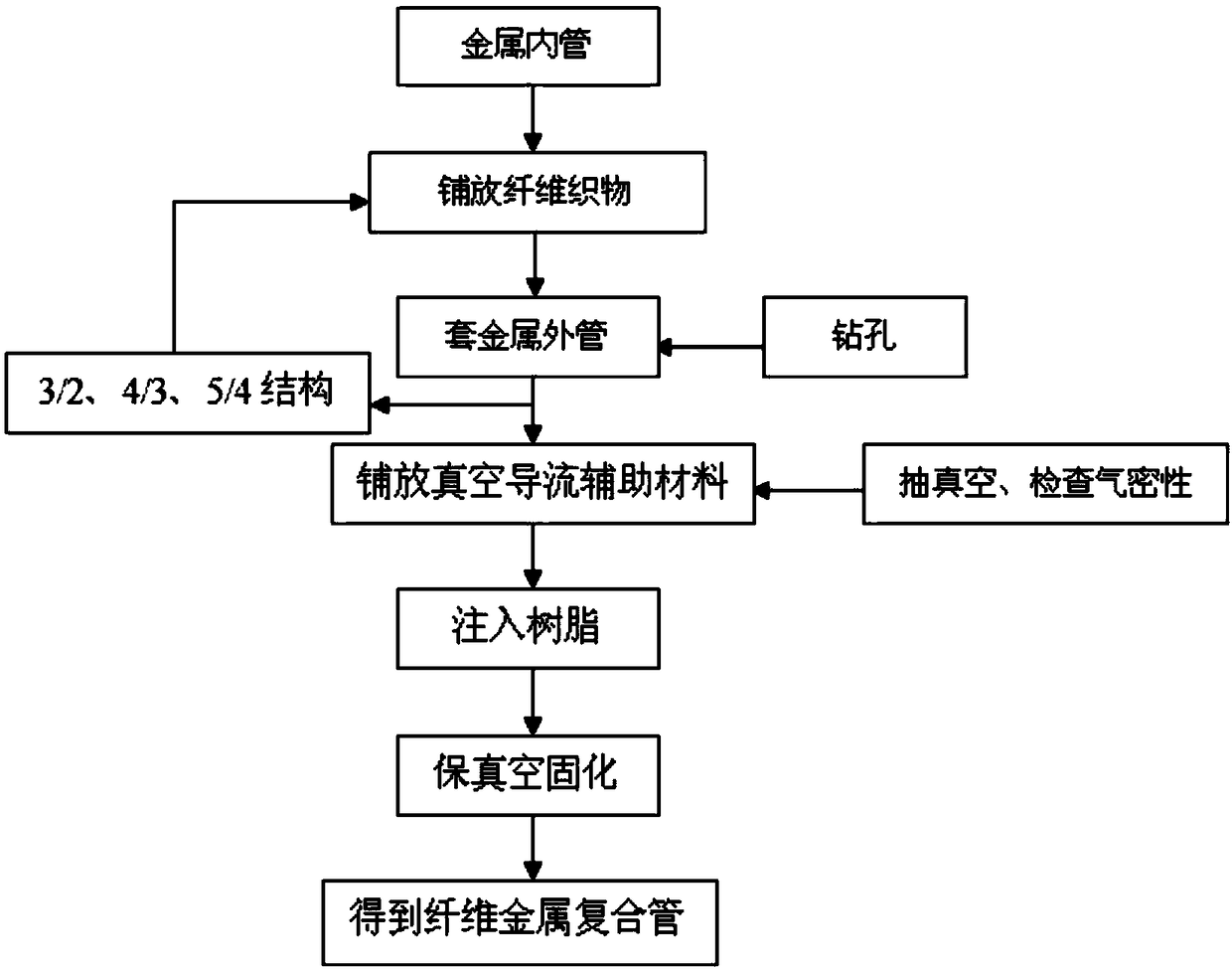

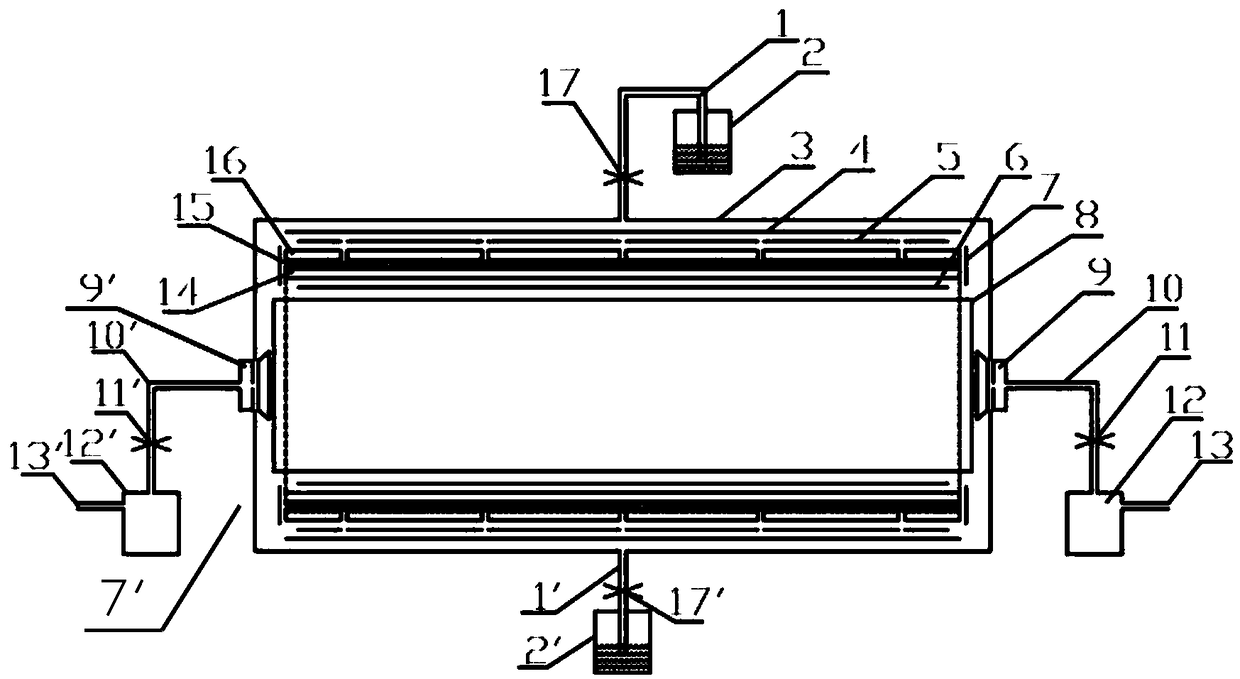

[0033] In the first step, a 6061 aluminum alloy round tube with an outer diameter of 38 mm and an inner diameter of 35 mm and a length of 300 mm is selected as the inner tube, and its surface is treated by phosphoric acid anodizing. Cut a unidirectional glass fiber woven cloth with a length of 600 mm and a width of 300 mm (spread 5 layers), pretreatment: extract with acetone as a solvent in a Soxhlet extractor for 48 hours, dry at 105°C for 1 hour, activation treatment: first immerse in 80°C HC1:H 2 o 2 :H 2 O=1:1:5 solution for 5min, rinsed with distilled water several times, in 80°C NH 3 :H 2 o 2 :H 2 O=1:1:5 solution was treated for 5 minutes, finally treated with 0.5% silane coupling agent / ethanol solution for 30 minutes, and dried at 105°C. Wrap the pretreated and activated unidirectional glass fiber woven cloth on the aluminum tube (the 0° direction is parallel to the axis direction of the aluminum tube);

[0034] The second step is to select a 6061 aluminum alloy...

Embodiment 2

[0040] The first step is to select a 6061 aluminum alloy round tube with a small head outer diameter of 30mm and an inner diameter of 27mm, a large head with an outer diameter of 58mm and an inner diameter of 55mm and a length of 300mm as the inner tube, and perform surface treatment by phosphoric acid anodizing. Cut out a unidirectional glass fiber woven cloth with an isosceles trapezoidal shape of 95mm in length, 185mm in length at the bottom, and 300mm in height (4 layers), pretreatment: extract with acetone as a solvent in a Soxhlet extractor for 48 hours, and dry at 105°C After 1h, activation treatment: first immerse in HC1:H at 80°C 2 o 2 :H 2 O=1:1:5 solution for 5min, rinsed with distilled water several times, in 80°C NH 3 :H 2 o 2 :H 2 O=1:1:5 solution was treated for 5 minutes, finally treated with 0.5% silane coupling agent / ethanol solution for 30 minutes, and dried at 105°C. Wrap the pretreated and activated unidirectional glass fiber woven cloth on the alumi...

Embodiment 3

[0047] In the first step, a TA2 titanium alloy square tube with an outer diameter of 46 mm, a thickness of 1 mm and a length of 200 mm is selected as the first layer of metal tube, and the surface is treated by acetone ultrasonic cleaning. Cut a biaxial carbon fiber woven cloth with a length of 1500mm and a width of 200mm (spread 8 layers) as the first fiber layer, pretreatment: extract with acetone as a solvent in a Soxhlet extractor for 48 hours, and dry at 105°C for 1 hour. Activation treatment: first immerse in HC1:H at 80°C 2 o 2 :H 2 O=1:1:5 solution for 5min, rinsed with distilled water several times, in 80°C NH 3 :H 2 o 2 :H 2 O=1:1:5 solution was treated for 5 minutes, finally treated with 0.5% silane coupling agent / ethanol solution for 30 minutes, and dried at 105°C. Wrap the pretreated and activated biaxial carbon fiber woven cloth on the titanium tube;

[0048] In the second step, a TA2 titanium alloy square tube with an outer diameter of 48 mm, a thickness ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com