Gluing and paper-folding device for processing of insulating crepe paper tube

A technology of insulating crepe paper and glue brush, which is applied in the direction of paperboard winding articles, etc., can solve the problems of difficult to control the bending position, glue on the brazing rod or carrier surface, and difficulty in removing the brazing rod, so as to ensure accuracy and reduce equipment The effect of cost input and convenient assembly

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

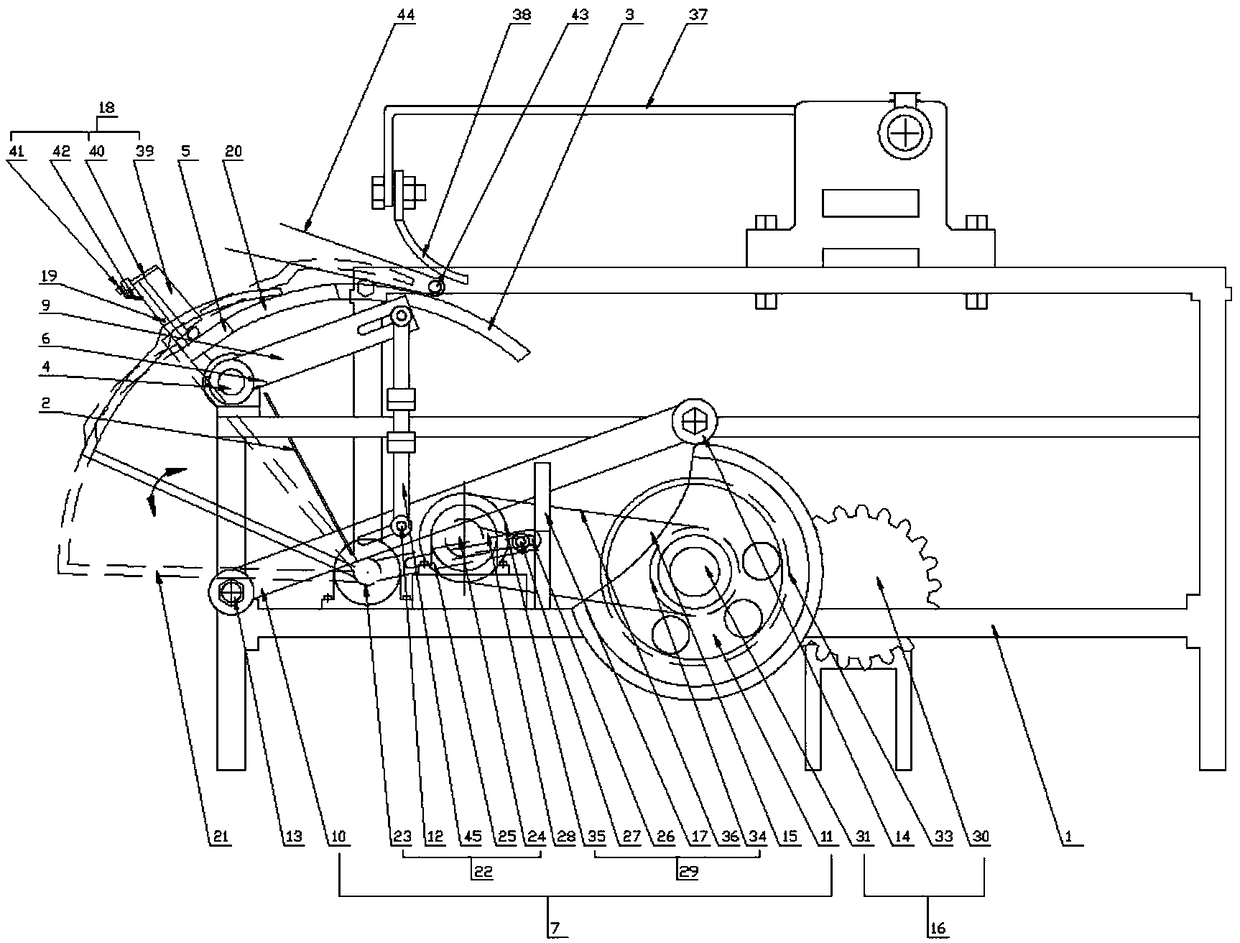

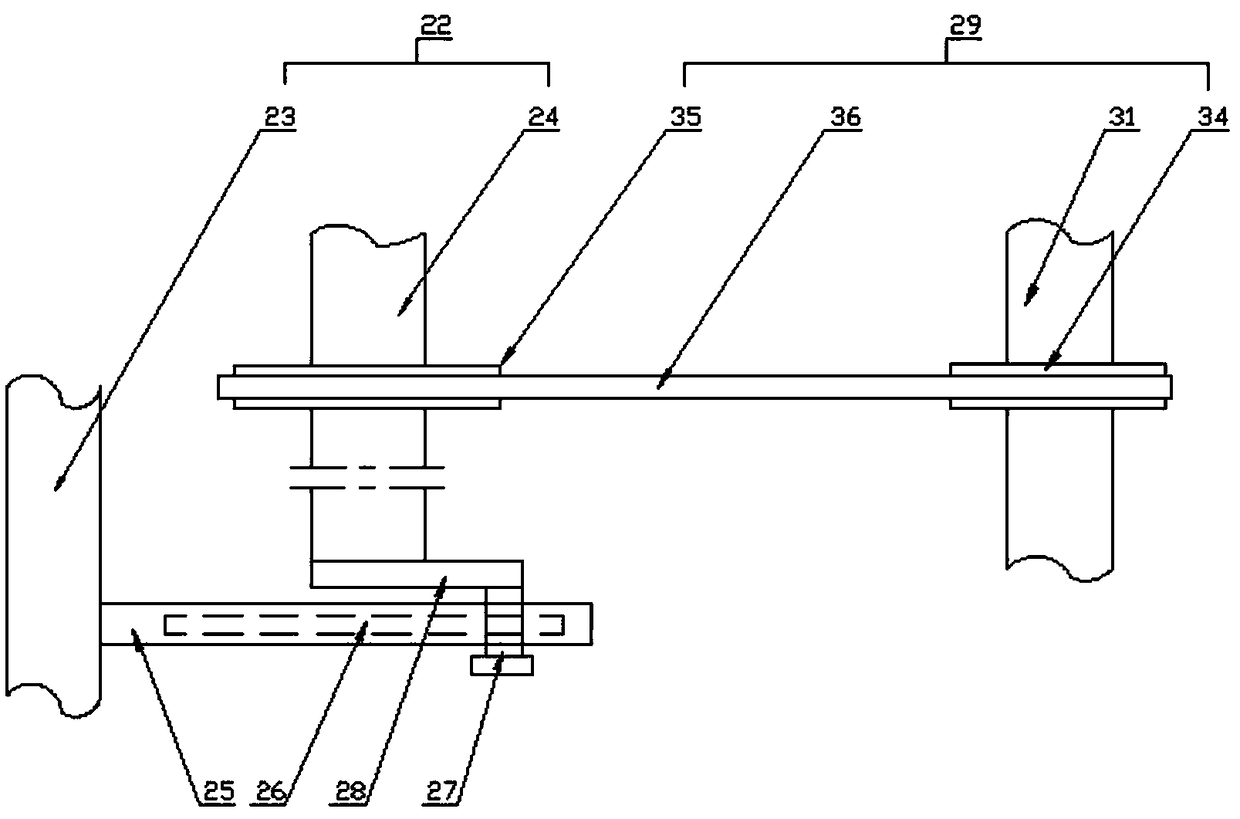

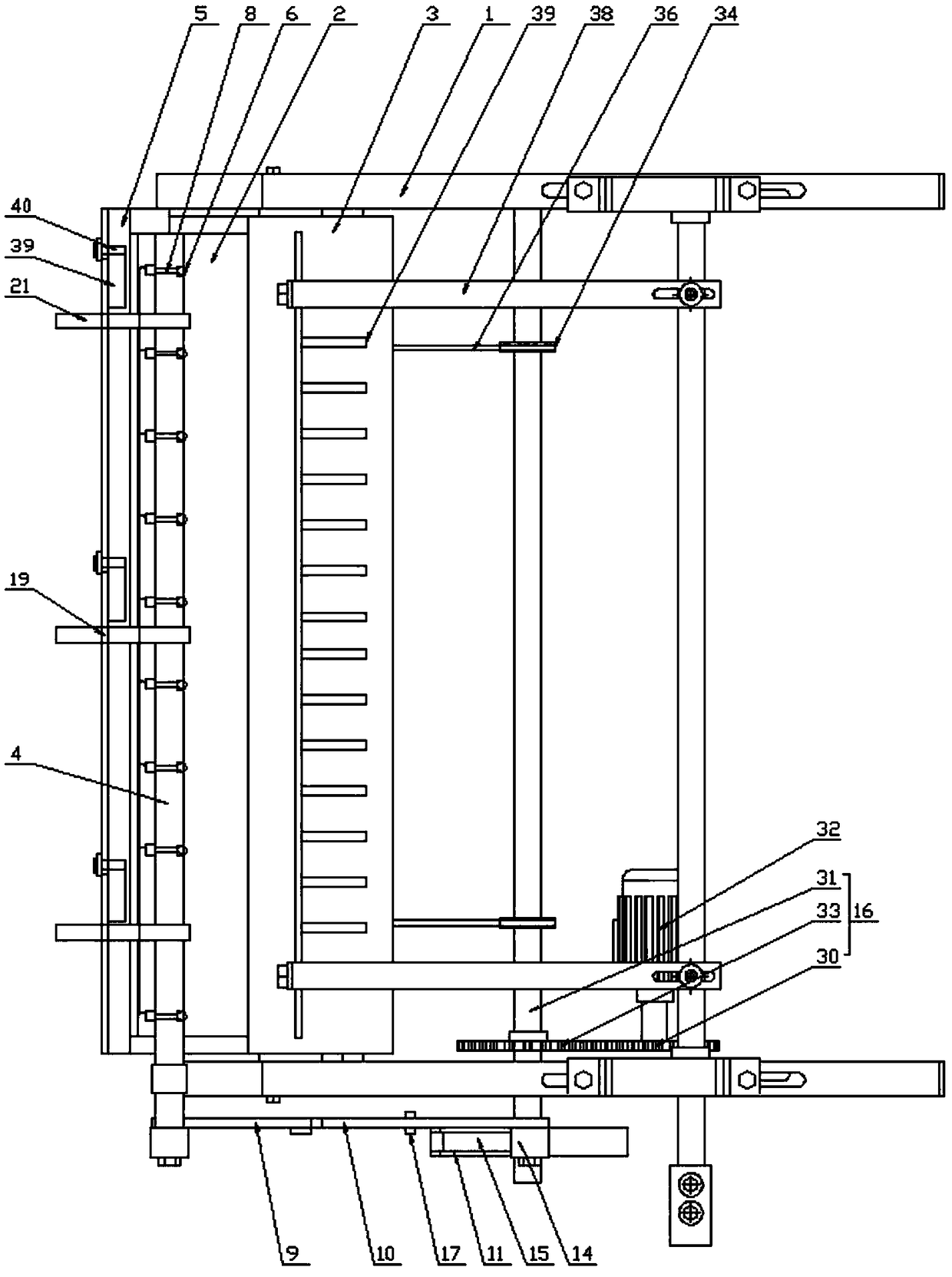

[0017] The specific embodiments of the present invention will be further described below in conjunction with the accompanying drawings.

[0018] A gluing origami device for insulating crepe paper tube processing, comprising a frame 1, wherein, the frame 1 is provided with a baffle 2 and a guide plate 3, and the top of one side of the baffle 2 is provided with a first shaft 4 and the brazing frame 5, the first shaft body 4 is provided with a number of rubber brushes 6, and a first deflection mechanism 7 is provided between the first shaft body 4 and the frame 1, and a glue gun 8 is provided on one side of the rubber brush 6, The glue gun 8 is fixed to the first shaft body 4, and several glue guns 8 share one main rubber hose, which is used to infiltrate several rubber brushes 6 with continuous synchronous arch glue for continuous production;

[0019] The first deflection mechanism 7 is used to drive the first shaft body 4 to intermittently deflect back and forth on the frame 1,...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap