Multi-layer amorphous alloy structure and weaving method thereof for protection equipment

An amorphous alloy and equipment technology, which is applied in protective equipment, protective equipment, protective clothing, etc., can solve the problems that the knife puncture cannot play an effective protective role, does not conform to the structural design, and cannot be achieved, so as to improve the defense against non-penetration. Sexual damage ability, improve defense penetration ability, improve the effect of energy absorption effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The present invention will be further described below in conjunction with the accompanying drawings.

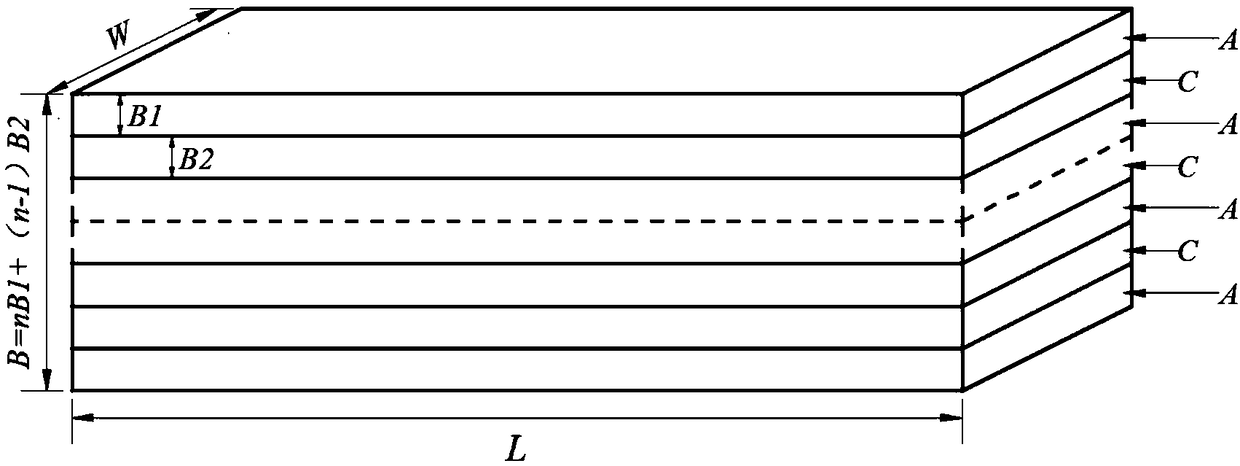

[0020] see figure 1 A multi-layer amorphous alloy structure includes several layers of amorphous alloys, and the adjacent layers of amorphous alloys are bonded by rubber or ETBN toughened epoxy resin. The amorphous alloy adopts titanium-based, zirconium-based and iron-based amorphous alloys.

[0021] figure 1 Among them, A represents the amorphous alloy layer, C represents the polymer layer, W represents the width of the multilayer amorphous alloy strip, B1 represents the thickness of the amorphous strip layer in the multilayer amorphous alloy, and B2 represents the multilayer amorphous alloy The thickness of the polymer layer in the crystal alloy, B=nB1+(n-1)B2 represents the overall thickness of the multilayer amorphous alloy strip, and L represents the length of the multilayer amorphous alloy strip.

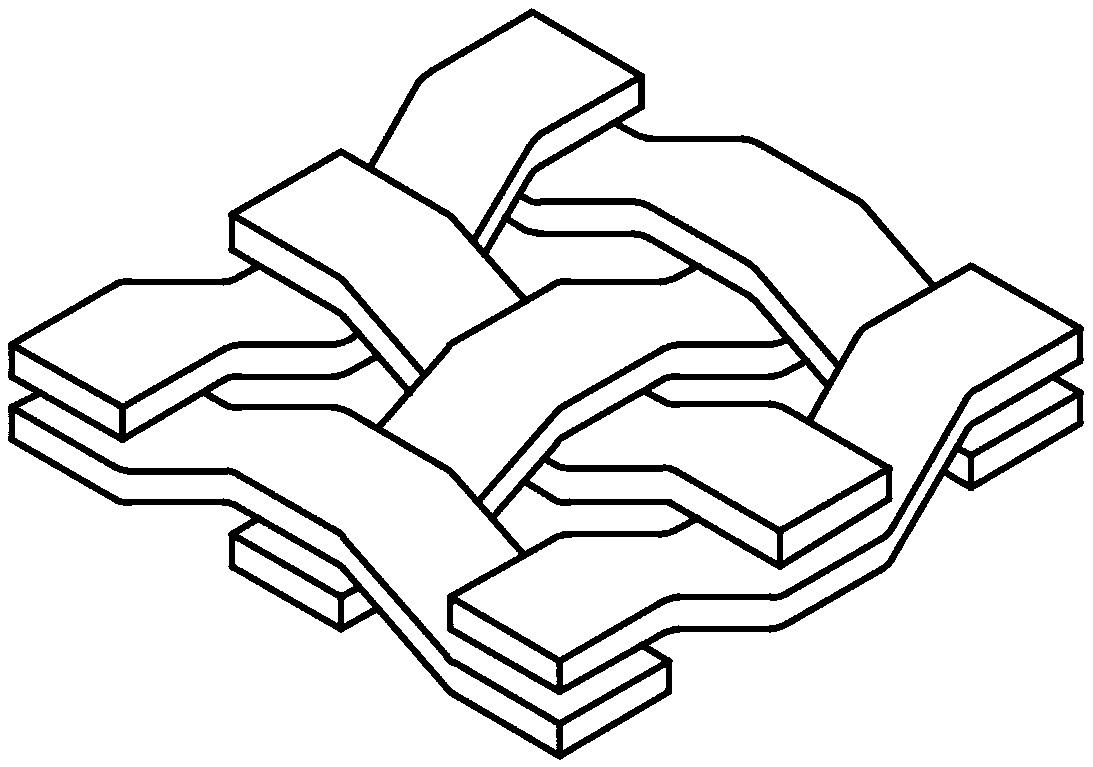

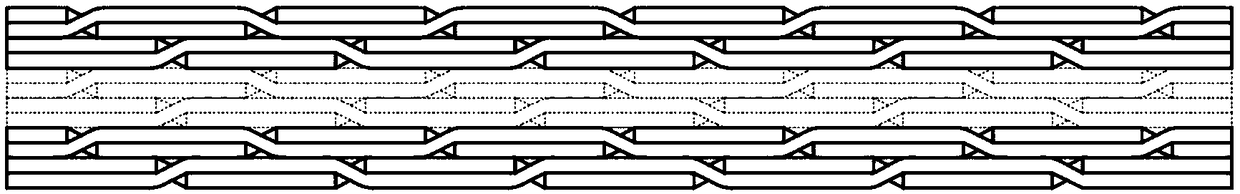

[0022] A method for weaving protective equipment using a multi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| strength | aaaaa | aaaaa |

| strength | aaaaa | aaaaa |

| strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com