Concrete capable of inhibiting early crack propagation

A technology of initial cracks and concrete, which is applied in the field of concrete materials, can solve the problems of high hazards, etc., achieve the effect of low material cost, good durability and strength, and inhibit the development of cracks

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0019] Embodiment: This embodiment specifically relates to a concrete that inhibits the development of initial cracks. Ordinary Portland cement, fly ash, and slag powder are used as cementing materials, and natural stones and natural sand are used as aggregates. Agent, shrinkage reducing agent, fiber, etc. The concrete construction scheme in this example is similar to ordinary concrete, and the difficulty of use is low. The resulting concrete has high strength and good durability, and can significantly inhibit the development of initial cracks.

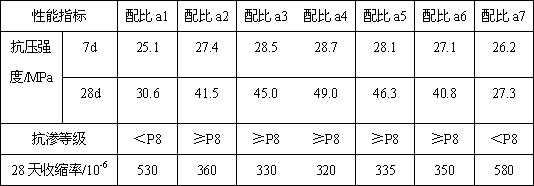

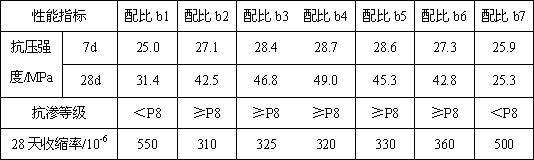

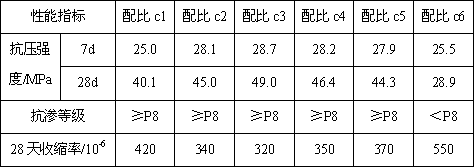

[0020] The weight ratio of each component of the concrete in this example is: Portland cement 100, natural sand 260-320, natural stone 370-430, fly ash 20-30, slag powder 20-35, water reducer 0.05 -2.00, swelling agent 0-10, shrinkage reducing agent 0-3, fiber 0-0.3, water 50-80. Among them, the expansion agent is magnesium oxide type expansion agent or sulfoaluminate expansion agent, the fiber is polypropylene fiber, the shrinkage r...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com