Red-brown composite material doped with manganese tungstate modified ASA and preparation method thereof

A technology for manganese tungstate modification and composite materials, which is applied in the field of reddish-brown composite materials doped with manganese tungstate modified ASA and its preparation. Temperature, beneficial to environmental protection and human health, reducing the effect of adding

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0043] (1) Preparation of reddish-brown filler: according to the ratio of raw materials described in Table 1, MnCO 3 Add in the dilute hydrochloric acid of pH=3 and stir evenly (1 gram of MnCO 3 / 300ml dilute hydrochloric acid); then add Zn to it 5 (OH) 6 (CO 3 ) 2 , continue to stir to form a large amount of white massive precipitate; ultrasonic dispersion for 5 minutes, the massive precipitate is dispersed into fine particles, forming a uniform MnCO 3 -Zn 5 (OH) 6 (CO 3 ) 2 -HCl suspension; Na 2 WO 4 2H 2 O was dissolved in deionized water to prepare a solution with a concentration of 0.04mol / L, and then the solution was added to the MnCO 3 -Zn 5 (OH) 6 (CO 3 ) 2- in the HCl suspension, stirred for 15 minutes to make it evenly mixed; adjusted the pH to 5 with dilute hydrochloric acid with pH = 1, and transferred to the reaction kettle; put the reaction kettle in an oven, and kept it at 150°C for 6 hours; Wash twice with deionized water and absolute ethanol su...

Embodiment 2

[0045] Embodiments 2, 3, and 4 all follow the above-mentioned steps, and the ratios of the required raw materials are shown in Table 1 and Table 2.

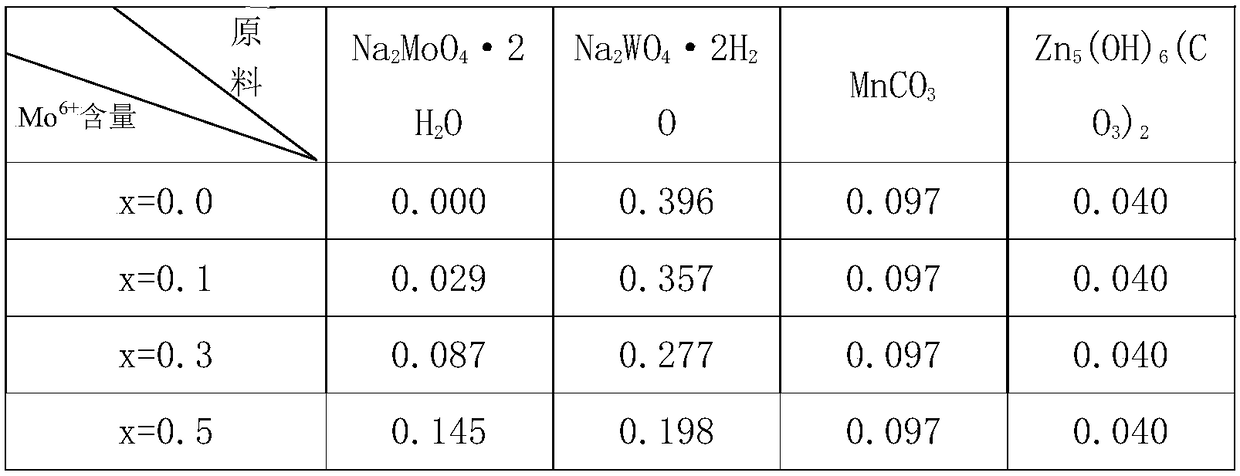

[0046] Table 1 general formula is Mn 0.7 Zn 0.3 Mo x W 1-x o 4 Raw material ratio and ingredient list of reddish-brown filler

[0047]

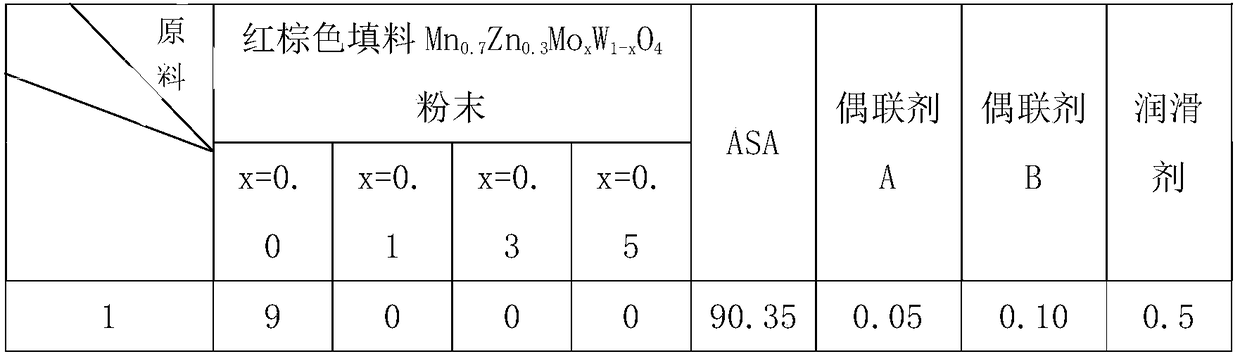

[0048] Table 2 Proportion of reddish-brown composite material

[0049]

[0050]

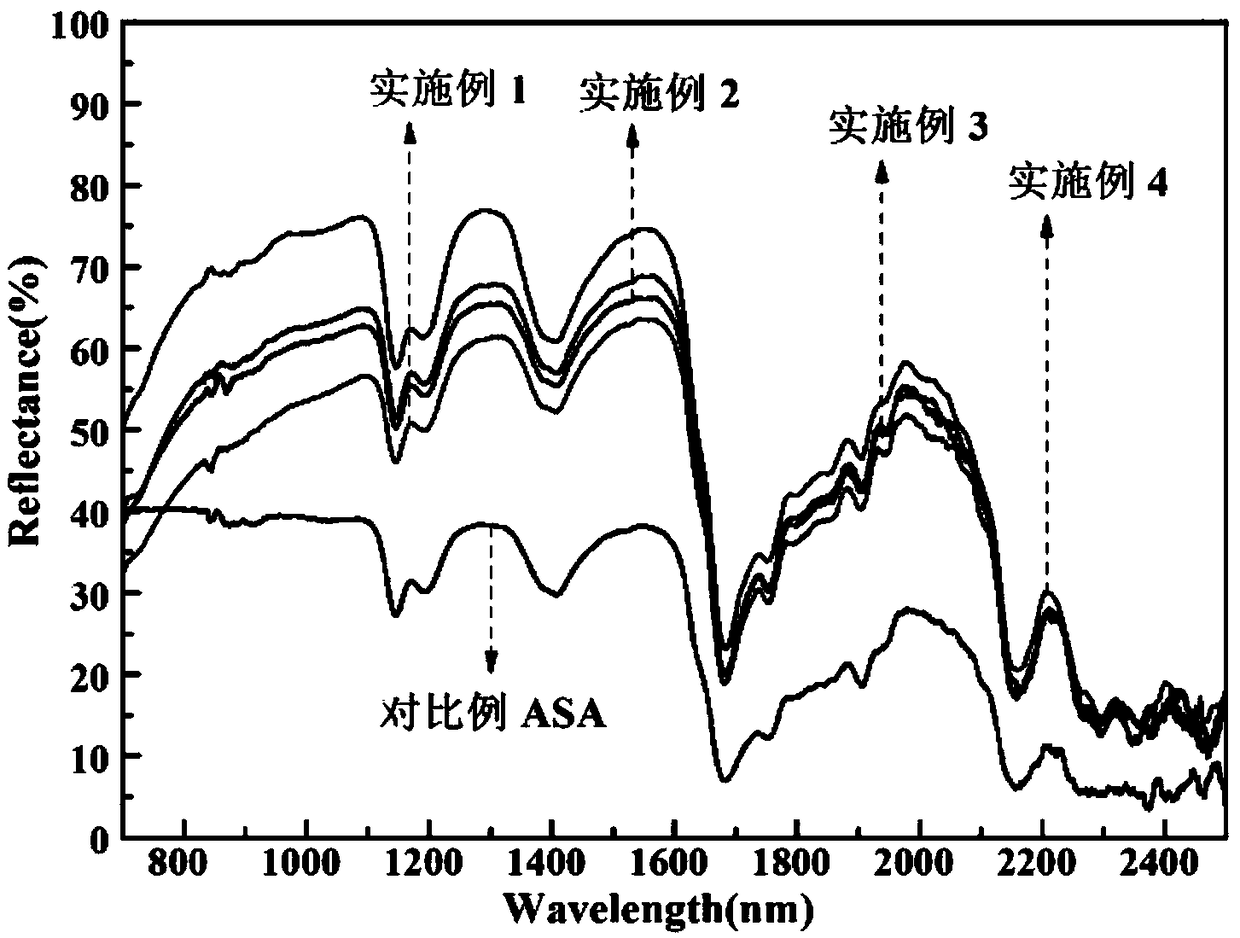

[0051] In order to check the near-infrared reflection performance of the present invention doped manganese tungstate modified ASA reddish-brown composite material, to evaluate its thermal aging resistance, the reddish-brown composite material in the embodiment described in Table 2 was compared with the commercially available ASA Resins were compared with materials (comparative examples) prepared in the same manner as in the examples. Among them, the instrument used for testing the reflectance is an ultraviolet-visible-near-infrared spectrophotometer (Shimadzu Company, Japan, UV-3600), BaSO 4 As a re...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap