A test method for measuring low temperature thermal insulation performance of vacuum conveying pipe

A low-temperature insulation and test method technology, applied in the direction of thermal development of materials, can solve problems such as differences in thermal insulation performance and difficult thermodynamic parameters, and achieve the effects of avoiding overflow, high test safety, and reducing the influence of heat leakage.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

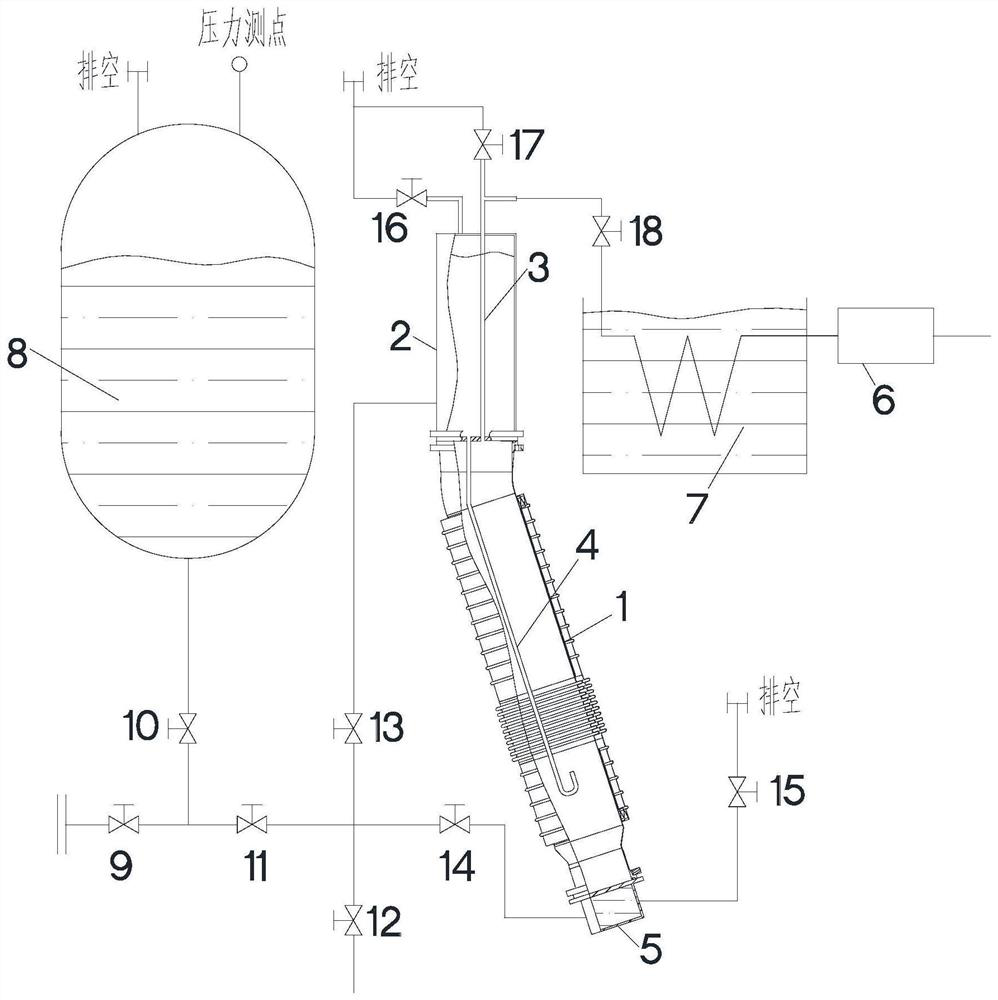

[0040] 1. Parametric model of low temperature insulation performance of vacuum conveying pipe

[0041] Considering that the low temperature insulation performance of vacuum pipeline determines the heat exchange rate between the inside and outside of the pipeline, the heat flow Q can be used as a characterization parameter of the insulation performance. The heat flow Q is defined as the heat that enters the interior (liquid hydrogen temperature) from the outside (normal temperature) of the pipeline per unit time. This parameter reflects the overall thermal insulation performance of the pipeline, which naturally includes heat exchange at complex structures such as flanges and compensators.

[0042] Since it is difficult to arrange temperature measuring points in the vacuum chamber of the pipeline, the heat flow Q cannot be calculated from the temperature test data. Considering that the heat from the outside of the pipeline into its interior will be absorbed by the liquid hydrog...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com