Simple method for separating and extracting asphaltene from asphalt at room temperature

A bituminous, room temperature technology, applied in the field of petroleum asphalt, can solve the problems of high economic cost, time and energy consumption, etc., and achieve the effects of high safety, avoiding potential safety hazards, and short standing time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

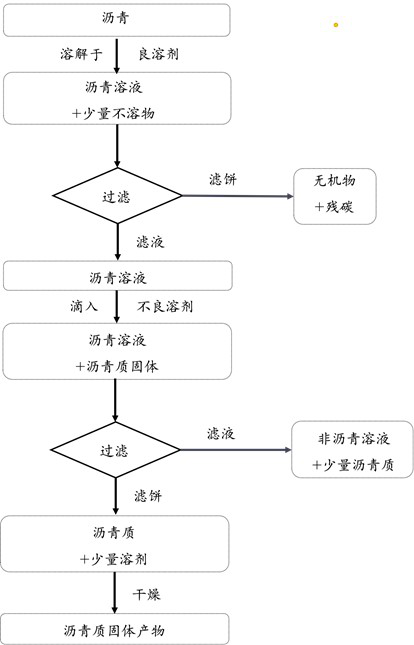

[0041] The present embodiment provides a method for extracting asphaltenes from asphalt at room temperature, comprising the following steps:

[0042] Put 5 g of base pitch into a 200 mL round-bottomed flask, pour 45 mL of xylene, and stir for 30 min to dissolve completely. The inorganic matter and residual carbon were removed by filtration (filter cake 1), rinsed with 5 mL of xylene, and the filtrate 1 was combined and set aside for later use.

[0043] Take a 500 mL beaker, pour 450 mL of n-heptane, and add magnetic stirring. The above filtrate was dropped into a beaker. After dropping for 30 min, it was filtered, the obtained filter cake 2 was rinsed with 50 mL of n-heptane, and the filtrate 2 was combined and set aside for later use.

[0044] Filter cake 2 was dried at room temperature for 8 h to constant weight to obtain asphaltenes. After weighing and calculating the yield (as shown in Table 1, the mass percentage of the obtained asphaltenes and matrix asphalt), it was ...

Embodiment 2

[0048] The present embodiment provides a method for extracting asphaltenes from asphalt at room temperature, comprising the following steps:

[0049] Put 5 g of base pitch into a 200 mL round-bottomed flask, pour 45 mL of toluene, and stir for 30 min to dissolve completely. Inorganic matter and residual carbon were removed by filtration (filter cake 1), rinsed with 5 mL of toluene, and the filtrate 1 was combined and set aside for later use.

[0050] Take a 500 mL beaker, pour 450 mL of n-heptane, and add magnetic stirring. The above filtrate was dropped into a beaker. After dropping for 30 min, it was filtered, the obtained filter cake 2 was washed with 50 mL of n-heptane, and the filtrate 2 was combined and set aside for later use.

[0051] Filter cake 2 was vacuum-dried at room temperature for 8 h to constant weight to obtain asphaltenes. After weighing and calculating the yield (as shown in Table 1), it was sealed and stored.

[0052] The subsequent recovery solvent an...

Embodiment 3

[0054] The present embodiment provides a method for extracting asphaltenes from asphalt at room temperature, comprising the following steps:

[0055] Put 5 g of base pitch into a 200 mL round-bottomed flask, pour 45 mL of xylene, and stir for 30 min to dissolve completely. The inorganic matter and residual carbon were removed by filtration (filter cake 1), rinsed with 5 mL of xylene, and the filtrate 1 was combined and set aside for later use.

[0056] Take a 500 mL beaker, pour 450 mL of n-hexane, and add magnetic stirring. The above filtrate was dropped into a beaker. After dropping for 30 min, filter, the obtained filter cake 2 was rinsed with 50 mL of n-hexane, and the filtrate 2 was combined and set aside for later use.

[0057] Filter cake 2 was dried at room temperature overnight (12 h) to constant weight to obtain asphaltenes. After weighing and calculating the yield (as shown in Table 1), it was sealed and stored.

[0058] The subsequent recovery solvent and eleme...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com