Quartz resonant current sensor

A current sensor and resonant technology, applied in the field of current sensors using high-Q quartz crystal resonators, can solve the problems of affecting measurement bandwidth, affecting measurement accuracy, and low sensitivity, and achieve the effect of simple driving circuit and detection circuit

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

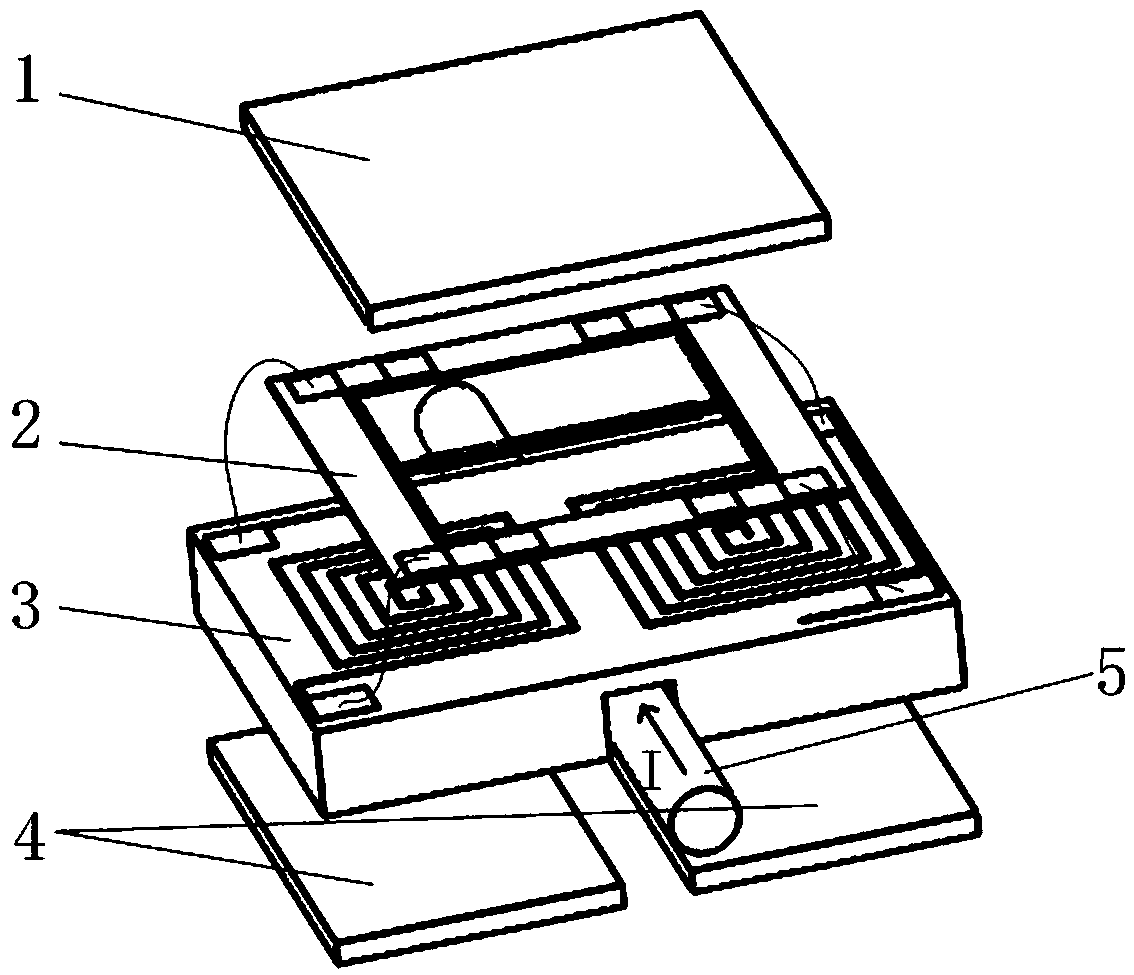

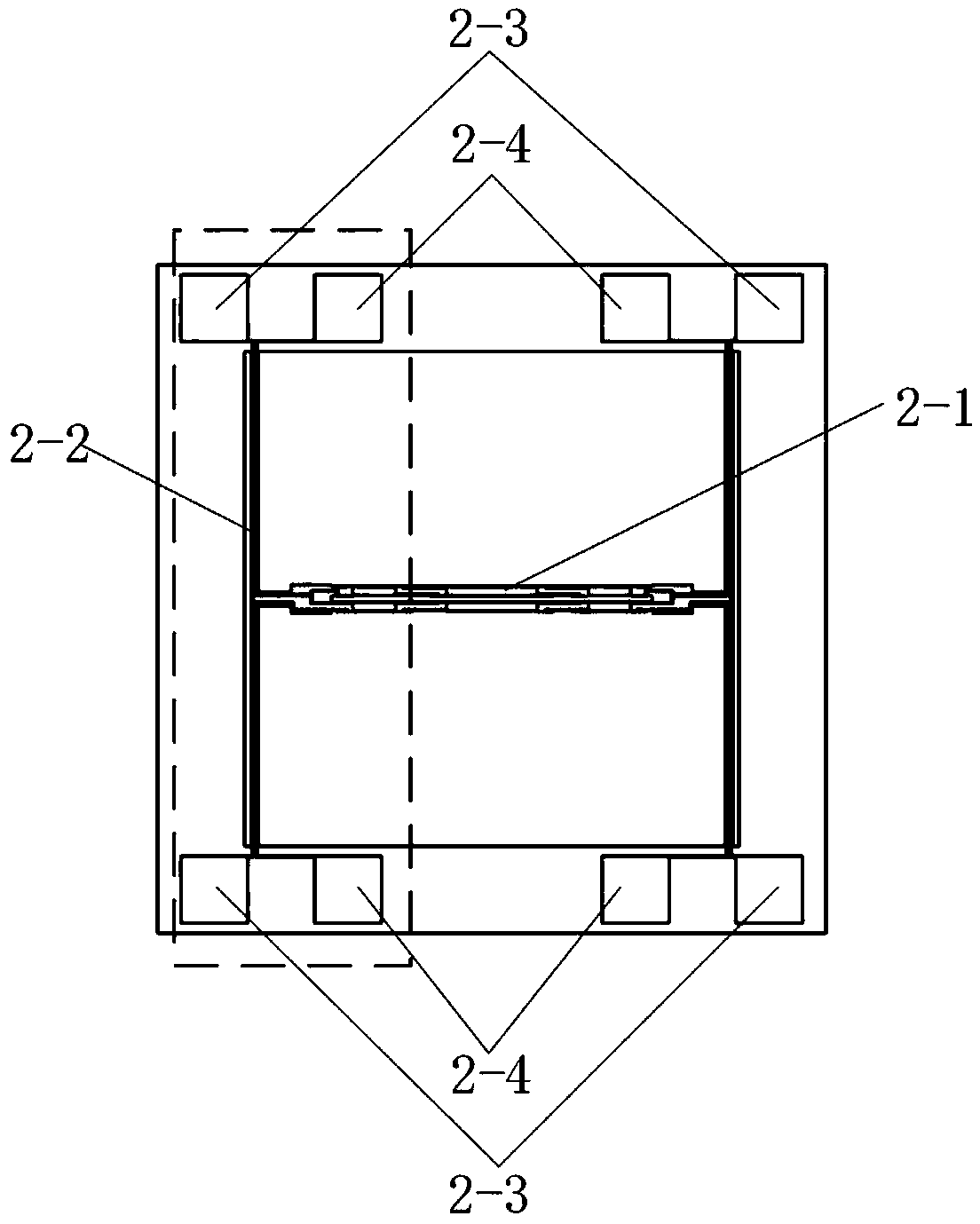

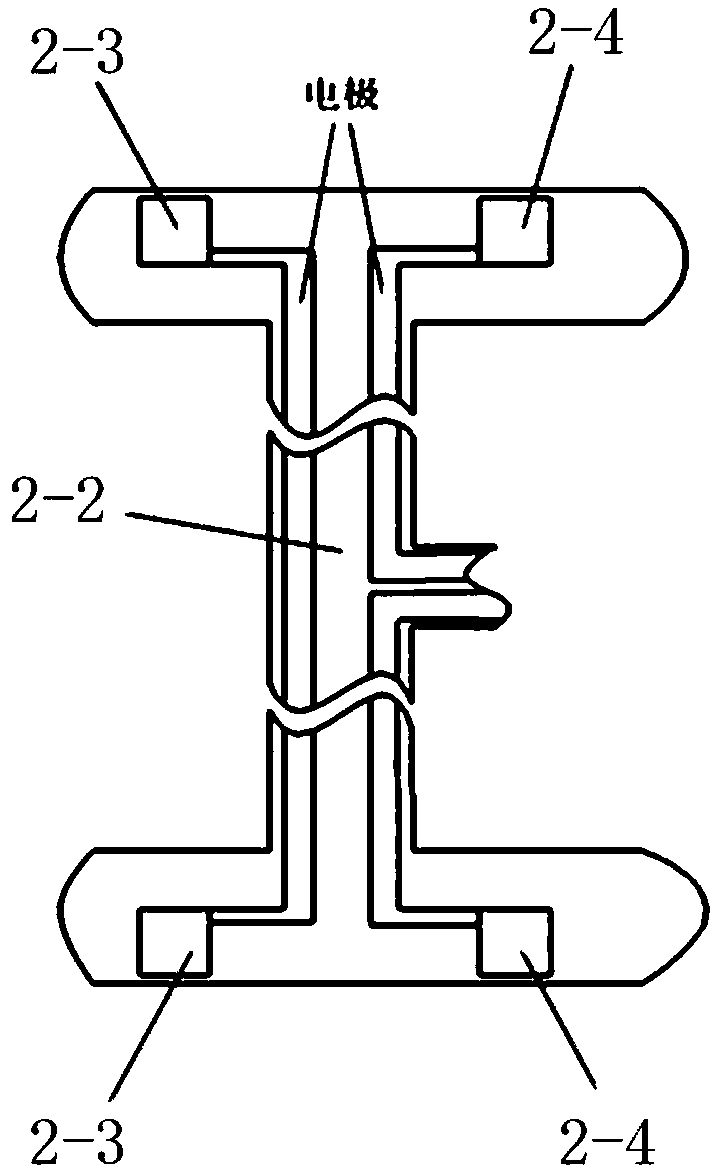

[0027] Such as figure 1 As shown, the quartz resonant current sensor shown in this embodiment includes a permanent magnet 1, a resonant current sensing unit 2, a PCB board with an induction coil 3, and a permanent magnet 4, wherein 5 is a current wire to be measured. The resonant current sensing unit 2 is an integrated structure made of a high-Q quartz crystal, such as figure 2 As shown, it includes a quartz tuning fork 2-1 fixed at both ends, a current-carrying elastic support beam 2-2, a current input pad 2-3 and a tuning fork excitation pad 2-4.

[0028] The quartz tuning fork 2-1 includes two vibrating beams with the same size and parallel to each other. Both ends of the quartz tuning fork 2-1 are respectively fixed in the middle of two current-carrying elastic support beams 2-2, and the length direction of the quartz tuning fork 2-1 is perpendicular to the length direction of the current-carrying elastic support beams 2-2, and the current-carrying elastic Both ends of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com