An optical fiber light-emitting structure, a liquid medicine dotting processing method, and a medicine dotting device

A technology of light-emitting structure and processing method, which is applied in the direction of bundled optical fibers, etc., to achieve the effect of increasing the scope of application, no starting current impact, and improving the use effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

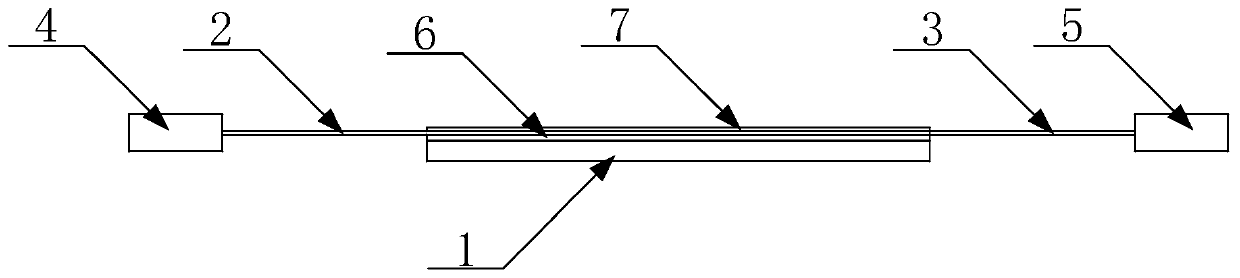

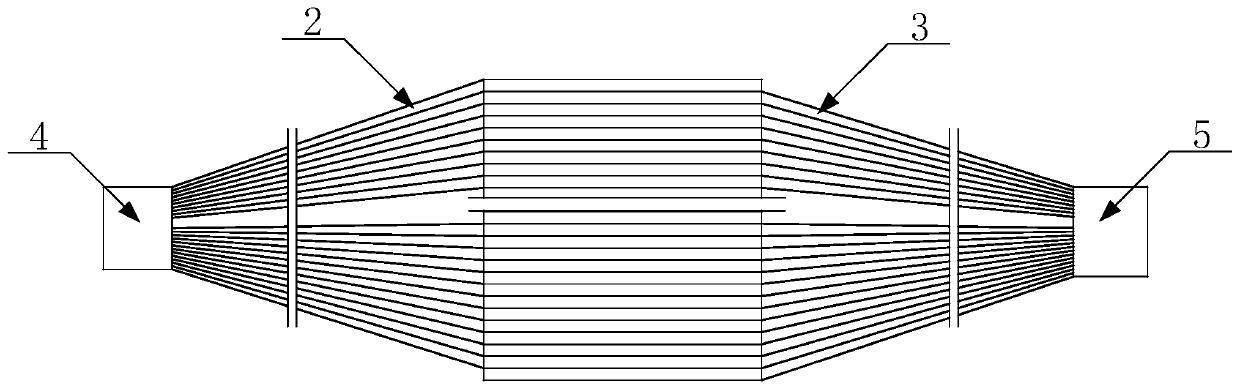

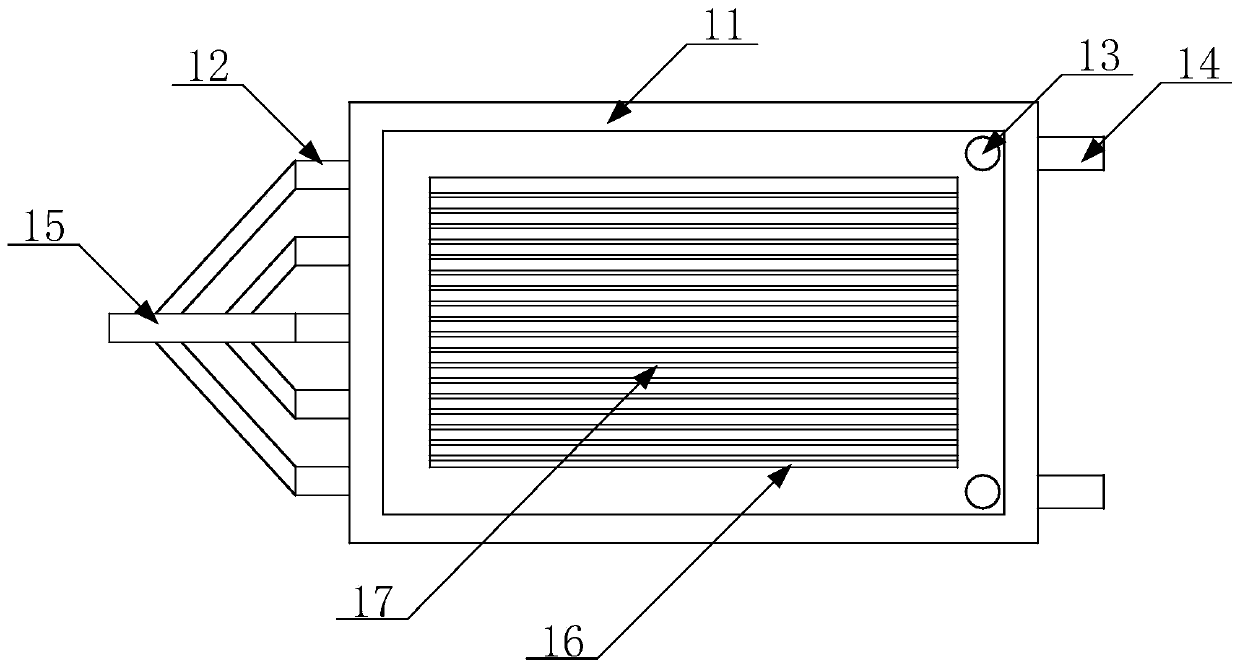

[0036] Such as figure 1 , 2 As shown, an optical fiber light-emitting structure includes a reflective sheet 1, an optical fiber layer arranged on the reflective sheet 1, a light source connected to the optical fiber layer, a small hole arranged on the upper side of the optical fiber layer, and an optical fiber layer arranged on the optical fiber layer and the reflective sheet 1. The bottom layer of transparent glue layer 6 between them, and the top layer of transparent glue layer 7 arranged on the upper side of the optical fiber layer; The surface is fixed on the reflective sheet 1, and the end of the leading line is connected to the light source; the small hole is formed after stripping the coating layer of the optical fiber, and the small hole is set against the reflective sheet 1.

[0037] When in use, the light from the light source is transmitted through the optical fiber, and when the light is transmitted to the position where the small hole is opened on the optical fib...

Embodiment 2

[0047] A method for processing liquid crystals of optical fiber light-emitting structures, comprising the following steps:

[0048] (1) Cut the reflector according to the requirement;

[0049] The shape of the reflective sheet is not limited, and specific shapes such as rectangle, circle, ellipse, polygon, star, and heart can be adjusted according to requirements. The reflective sheet can provide a certain support for the optical fiber, reduce the difficulty of installing the optical fiber, and has a certain degree of toughness, which can be bent within a certain range, so that it can fit well on the surface of different objects and improve the scope of application of the product .

[0050] (2) smear transparent glue on the upper surface of the reflective sheet and fix the optical fiber wiring on the reflective sheet through the transparent glue, and then make the transparent glue solidify into the bottom transparent glue layer by natural ventilation or low-temperature drying...

Embodiment 3

[0061] The only difference between this example and Example 2 is that the heating temperature of the low-temperature drying described in step (2), step (3) and step (5) is 85°C.

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com