A touch sensor and a touch display panel

A technology of touch sensing and substrate, which is applied in the fields of instruments, computing, electrical digital data processing, etc., and can solve problems such as poor etching of metal grids, low yield rate of touch sensors, and discoloration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

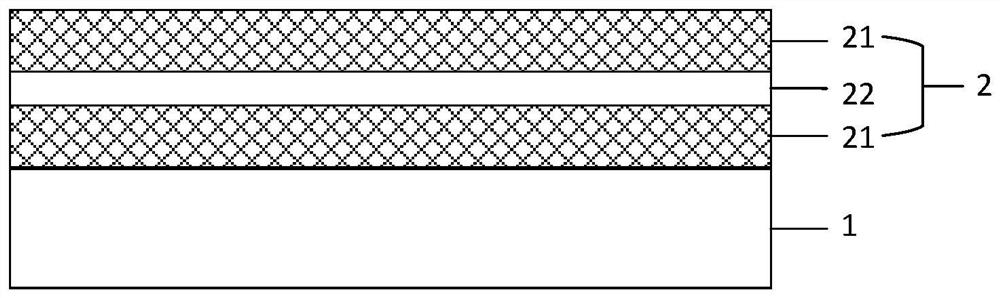

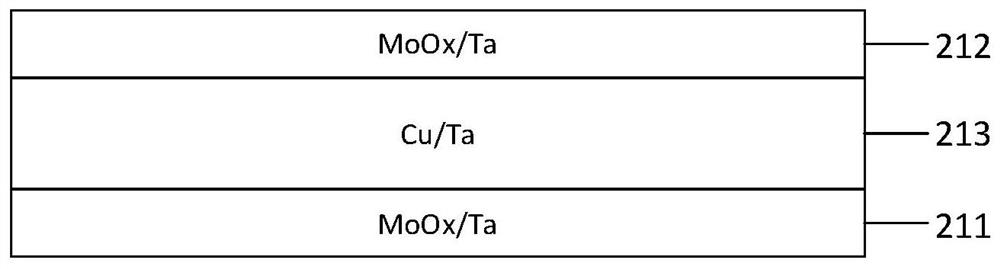

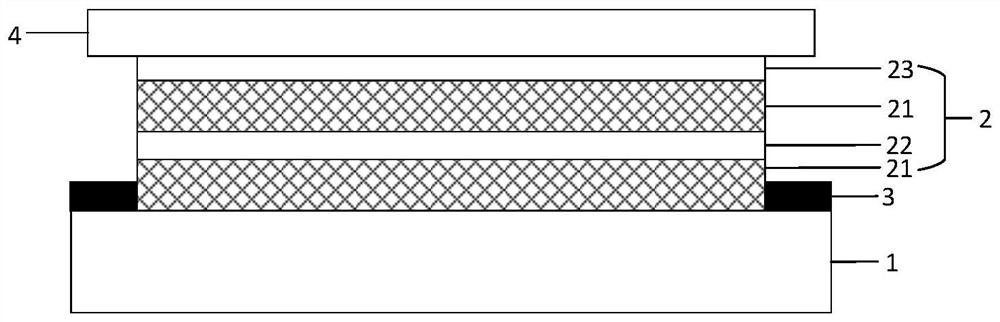

[0026] The core of the present invention is to provide a touch sensor. In the prior art, the conductive wire constituting the conductive grid layer is typically a three-layer structure having a sandwich type, wherein the conductive layer is located in the middle, and is a black layer on both sides. In the prior art, the conductive mesh layer is prepared in one etching process in one etching process. In the etching process, a case where the blacking layer and the conductive layer have inconsistent amount, for example, if the side etching amount of the black layer is larger than the side etching of the conductive layer, the conductive layer is easily exposed to generate a different color. Situation; if the side etching of the black layer is significantly smaller than the side etching of the conductive layer, when the wire width of the conductive mesh is guaranteed, the conductive wire break, the ablation, and the line saw to tease, that is, when When the surface of the blacking laye...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com