RFID printed antenna and preparation method thereof

A technology for printing antennas and substrates, which is applied to record carriers used in machines, instruments, computer components, etc., can solve the problems of poor waterproof and folding resistance, pollute the environment, and low precision, and achieve good waterproof, reduce production costs, and fire prevention and conduction performance effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

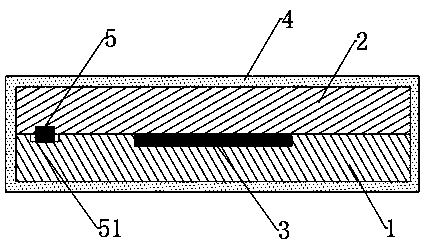

[0020] Such as figure 1 As shown, the present invention provides a RFID printed antenna, including a substrate 1, a protective plate 2, a printed antenna 3 and a polymer film layer 4, and the printed antenna 3 is printed between the substrate 1 and the protective plate 2 using conductive ink The printed conductive antenna, the protective plate 2 and the substrate 1 are provided with a matching positioning protrusion 5 and a positioning groove 51, and the polymer film layer 4 is sealed and coated on the outside of the substrate 1 and the protective plate 2.

[0021] In the present invention, both the protective plate and the base plate can be made of plastic material, and the shape and size of the protective plate are the same as those of the base plate.

[0022] As a further preference of the present invention, both the protective plate and the substrate are made of paper materials, and the conductive ink is carbon-based conductive ink.

[0023] As another preference of the p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com