a high quality ga 2 o 3 Thin film and its heteroepitaxial preparation method

A heterogeneous epitaxial, high-quality technology, applied in semiconductor/solid-state device manufacturing, electrical components, circuits, etc., can solve problems such as poor quality of heterogeneous epitaxial crystals

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

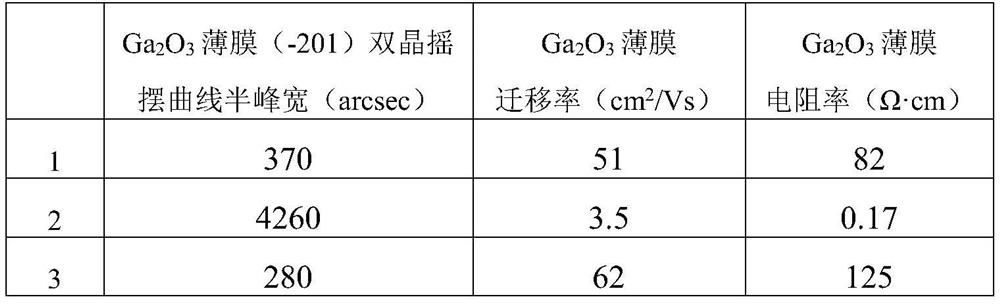

Embodiment 1

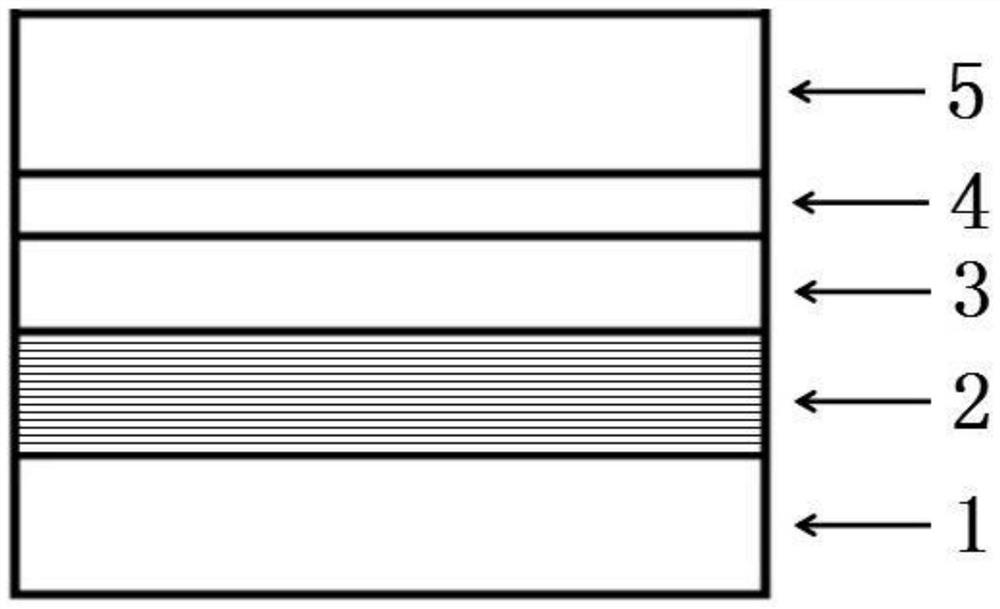

[0017] A high quality Ga 2 o 3 Heteroepitaxial thin films with structures such as figure 1 As shown, the c-plane sapphire substrate 1, the epitaxially grown GaN-based multilayer structure film 2 on the c-plane sapphire substrate 1, and the low-temperature oxidized low-temperature Ga 2 o 3 Oxide layer 3, low temperature Ga 2 o 3 High temperature oxidized high temperature Ga on oxide layer 3 2 o 3 Oxide layer 4, high temperature Ga 2 o 3 High-quality Ga epitaxially grown on oxide layer 4 2 o 3 layer 5; characterized in that: the GaN multilayer structure film 2 is made of AlN-Al 1-x Ga x Composed of N-GaN multi-layer films with a total thickness of 1000nm, among which AlGaN is a composition gradient buffer layer, and the uppermost layer is a high-quality GaN film; low-temperature Ga 2 o 3 The oxide layer 3 is made by low-temperature thermal oxidation of the upper surface (GaN film) of the GaN-based multilayer structure film 2; 2 o 3 Oxide layer 4 is made of low tem...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com