Sample grinding device

A technology of grinding samples and grinding discs, which is applied in the direction of grinding drive devices, measuring devices, grinding machines, etc., can solve problems such as over-grinding or grinding skew, and achieve the effects of avoiding skew, ensuring regular shape, and improving the quality of grinding samples

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

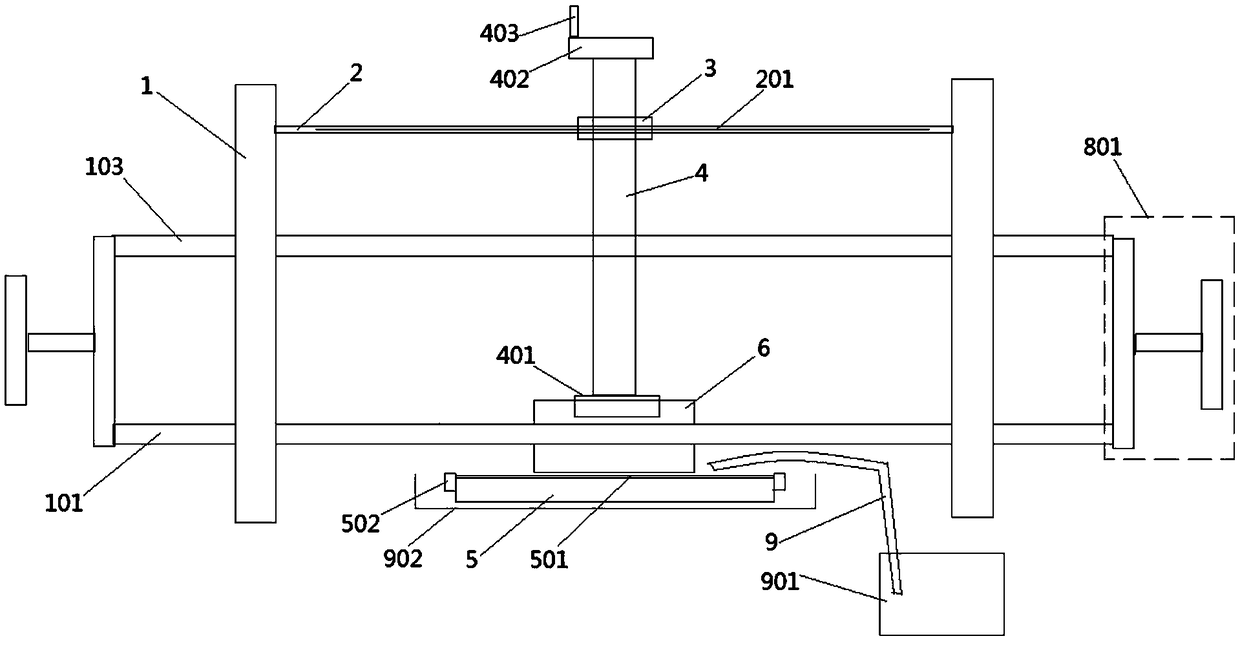

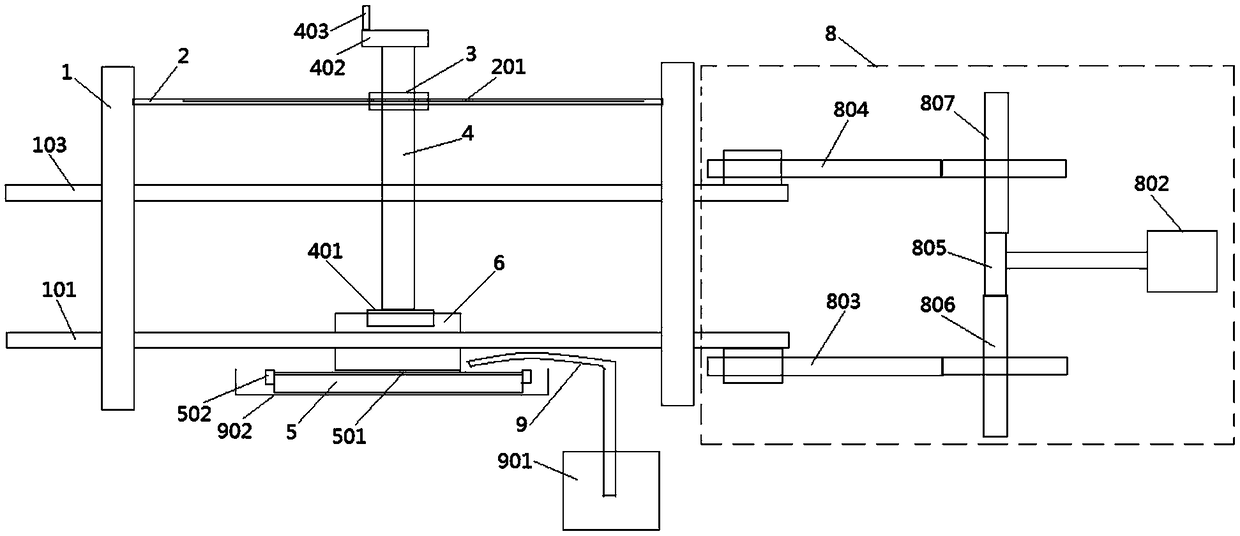

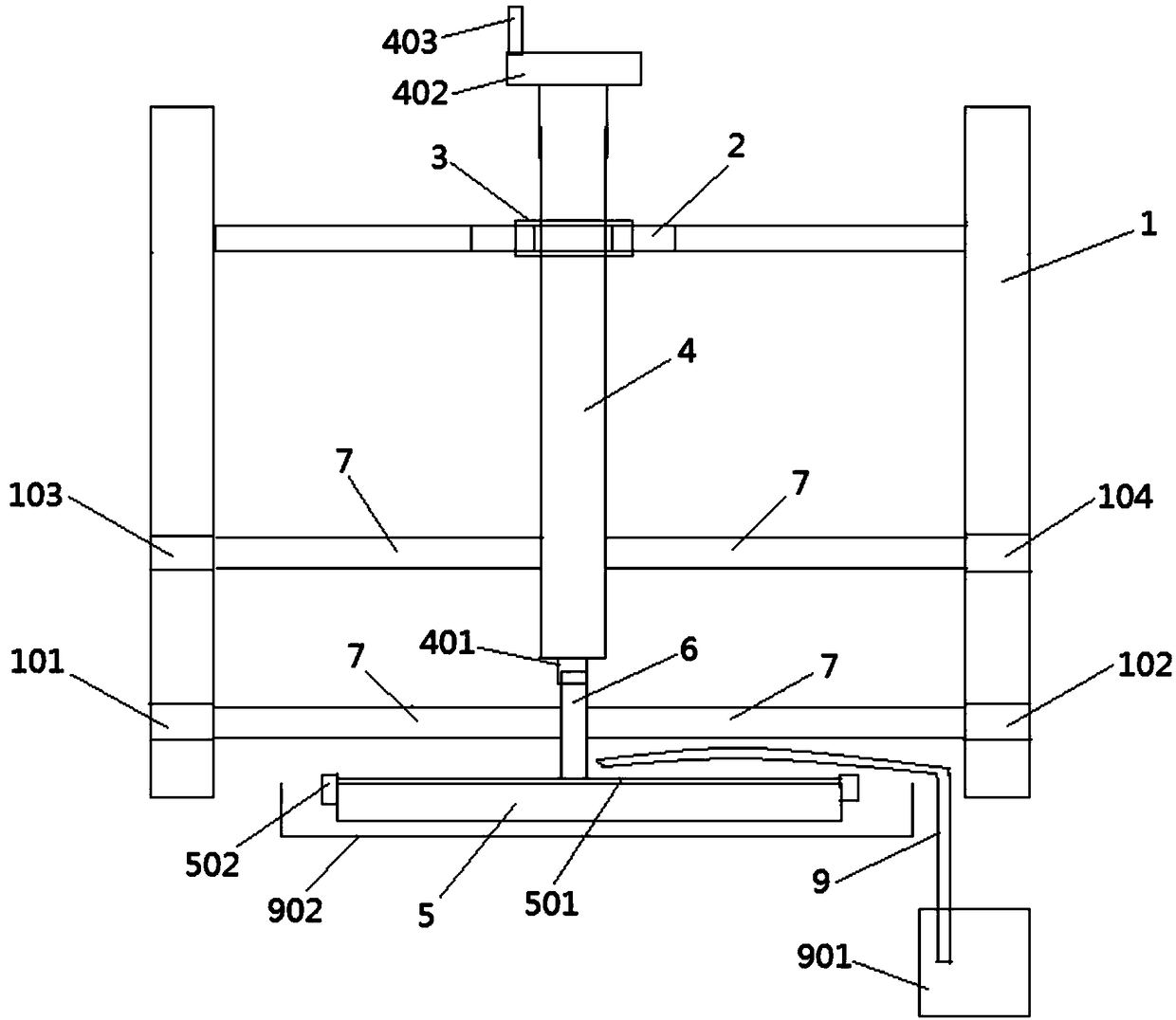

[0038] refer to Figure 1-Figure 3, a sample grinding device provided by an embodiment of the present invention, comprising two H-shaped brackets 1 and a grinding disc, the two H-shaped brackets 1 are symmetrically arranged on the left side and the right side of the grinding disc 5 Two crossbeams 2 are arranged on the upper end of the crossbeam 2, and sliding parts 3 are erected between the two crossbeams 2, and the sliding parts 3 move left and right along the crossbeams 2; The lower end of the pressing part 4 is provided with an elastic clamping part 401, and the sample 6 to be ground is inside the elastic clamping part 401; the first sliding rod 101, the second sliding rod 102, the first sliding rod 101, the second sliding rod 102, The third sliding bar 103 and the fourth sliding bar 104, the first sliding bar 101 and the second sliding bar 102 are located on the same horizontal plane, the third sliding bar 103 and the fourth sliding bar 104 are located on the same horizont...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com