A kind of canned corn kernel production technology with high lock freshness

A production process, corn kernel technology, applied in the directions of disinfection, heating, food science, etc., can solve the problems of increasing uncontrollable factors in the process flow, lack of sterilization treatment, etc., to avoid uncontrollable factors, good effect, and ensure the effect of yield

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0036] A high freshness-locked corn grain canned production process, comprising the following steps:

[0037] Step 1. Pretreatment: Peel the ears of fresh corn, precook them, thresh them, screen them, wash them, and dry them;

[0038] Step 2, grain selection: the pretreated corn grains are checked;

[0039] Step 3, cleaning and sterilizing the empty cans: cleaning and sterilizing the empty cans;

[0040] Step 4, canning and sealing: put the screened grains into the empty cans and then seal them;

[0041] Step 5. Sterilization: Sterilize the sealed cans in the sterilizer;

[0042] Step 6, drying: drying the surface of the sterilized can;

[0043] Step seven, vacuum detection;

[0044] Step 8: Coding and labeling, finished product storage;

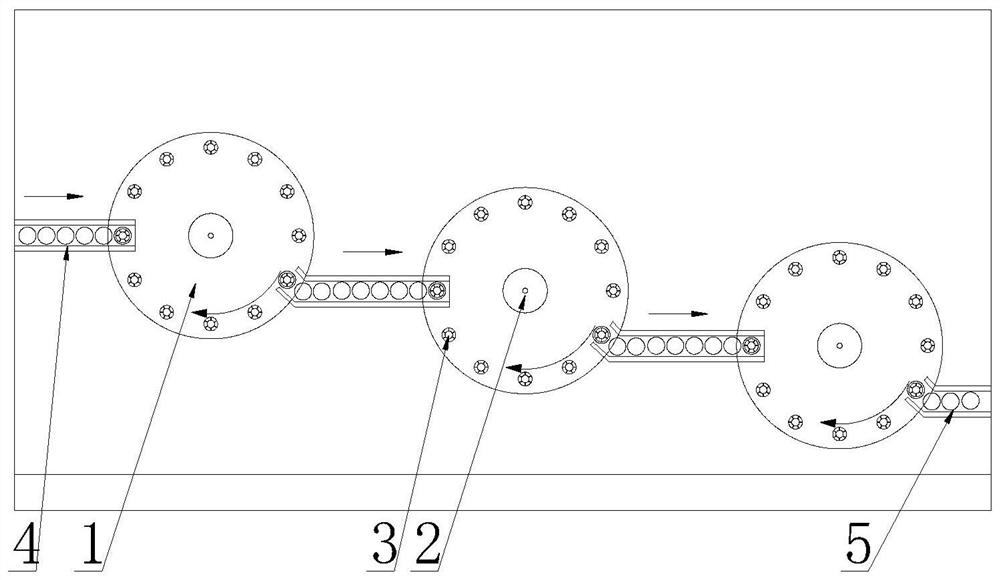

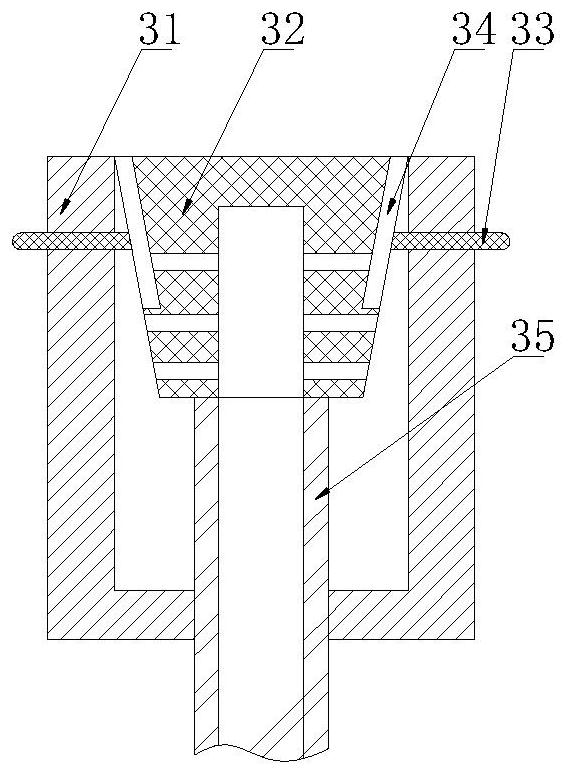

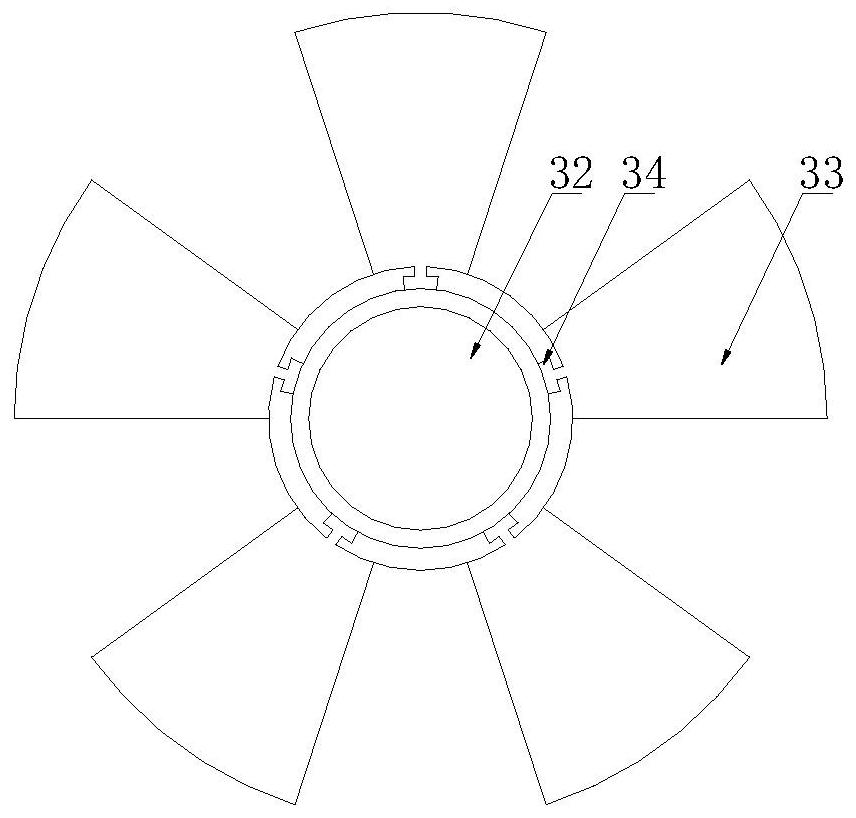

[0045] Step 3: The equipment used for the inclined sterilization of empty cans is an empty can sterilizer;

[0046] When filling in step 4, add soup into the tank of the seeds and seal it. The parts by weight of the soup are: water 100, ...

Embodiment 2

[0063] A high freshness-locked corn grain canned production process, comprising the following steps:

[0064] Step 1. Pretreatment: Peel the ears of fresh corn, precook them, thresh them, screen them, wash them, and dry them;

[0065] Step 2, grain selection: the pretreated corn grains are checked;

[0066] Step 3, cleaning and sterilizing the empty cans: cleaning and sterilizing the empty cans;

[0067] Step 4, canning and sealing: put the screened grains into the empty cans and then seal them;

[0068] Step 5. Sterilization: Sterilize the sealed cans in the sterilizer;

[0069] Step six, blow dry;

[0070] Step seven, vacuum detection;

[0071] Step 8: Coding and labeling, finished product storage;

[0072] Step 3: The equipment used for the inclined sterilization of empty cans is an empty can sterilizer;

[0073] When filling in step 4, add soup into the tank of the grains and seal it. The parts by weight of the soup are: water 100, rock sugar 2.5, salt 3.5, green pep...

Embodiment 3

[0080] A high freshness-locked corn grain canned production process, comprising the following steps:

[0081] Step 1. Pretreatment: Peel the ears of fresh corn, precook them, thresh them, screen them, wash them, and dry them;

[0082] Step 2, grain selection: the pretreated corn grains are checked;

[0083] Step 3, cleaning and sterilizing the empty cans: cleaning and sterilizing the empty cans;

[0084] Step 4, canning and sealing: put the screened grains into the empty cans and then seal them;

[0085] Step 5. Sterilization: Sterilize the sealed cans in the sterilizer;

[0086] Step six, blow dry;

[0087] Step seven, vacuum detection;

[0088] Step 8: Coding and labeling, finished product storage;

[0089] Step 3: The equipment used for the inclined sterilization of empty cans is an empty can sterilizer;

[0090] When filling in step 4, add soup into the tank of the seeds and seal it. The parts by weight of the soup are: water 100, rock sugar 2.8, salt 5, green pepper...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com