Production system and production method of regenerated high-impact polystyrene material

A technology for recycling polystyrene and polystyrene, applied in the field of plastic production, can solve the problems of low efficiency, loss of raw materials, and economic efficiency of enterprises, and achieve the effect of improving production efficiency, soft structure, and easy and fast cutting

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

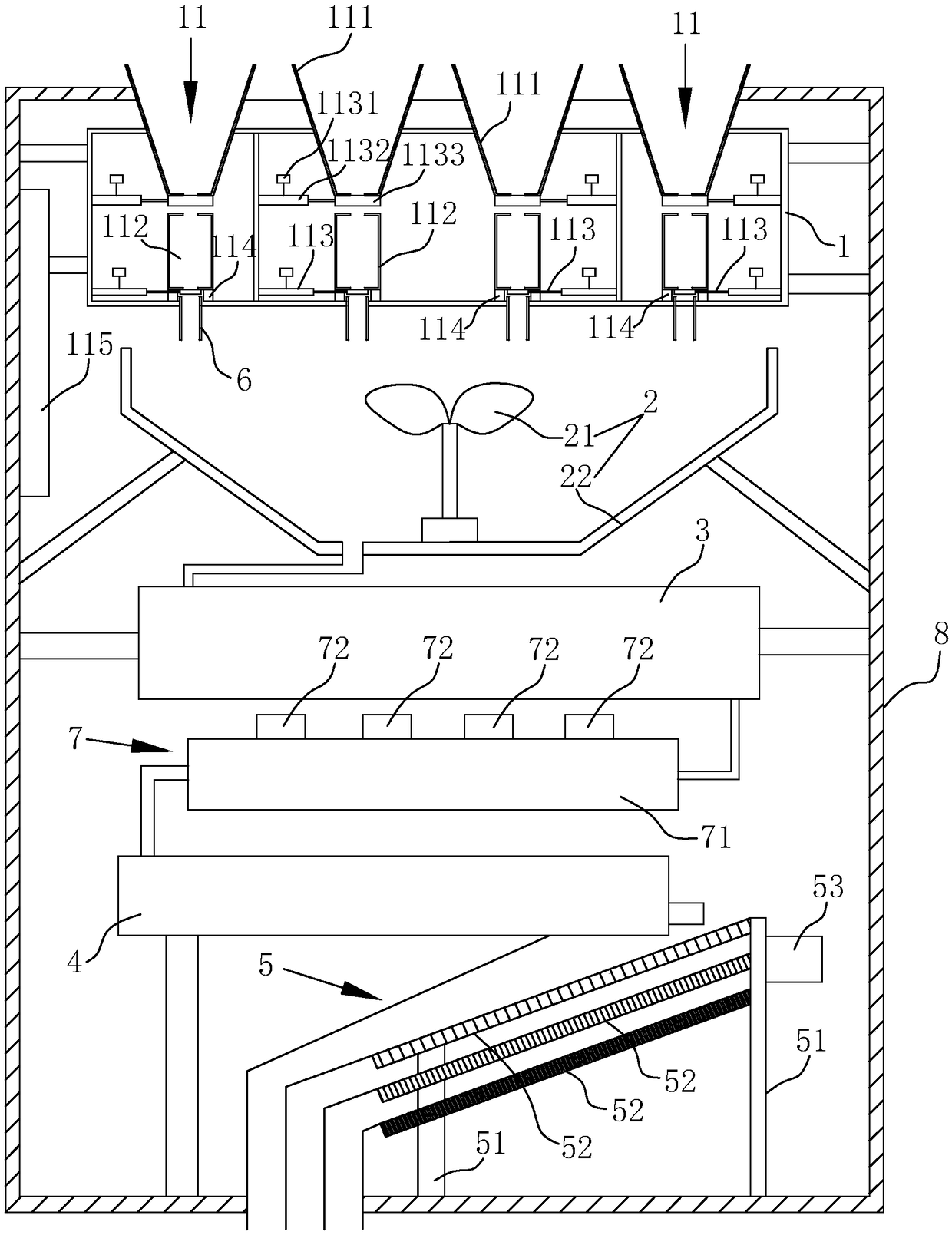

[0060] A production system for recycled high-impact polystyrene material, combining figure 1 As shown, it includes: an automatic raw material metering device 1 , a mixer 2 , an extruder 3 , a pelletizer 4 , a particle screening machine 5 , a pipeline 6 , a cooling device 7 and a box body 8 .

[0061] Mixer 2, extruder 3, and granulator 4 can be directly purchased in the market, and automatic raw material metering device 1, mixer 2, extruder 3, cooling device 7, granulator 4 and particle screening machine 5 are from top to bottom The bottom and bottom are arranged in sequence and are all arranged in the box body 8, and the above-mentioned many devices and equipment are integrated into the box body 8, which not only saves space, but also facilitates transportation and transfer of the production system.

[0062] The mixer 2 is provided with a mixing bucket 21 and a mixing assembly 22, and the mixer 2 is used to stir and mix the raw materials to form a first processing body; the a...

Embodiment 2

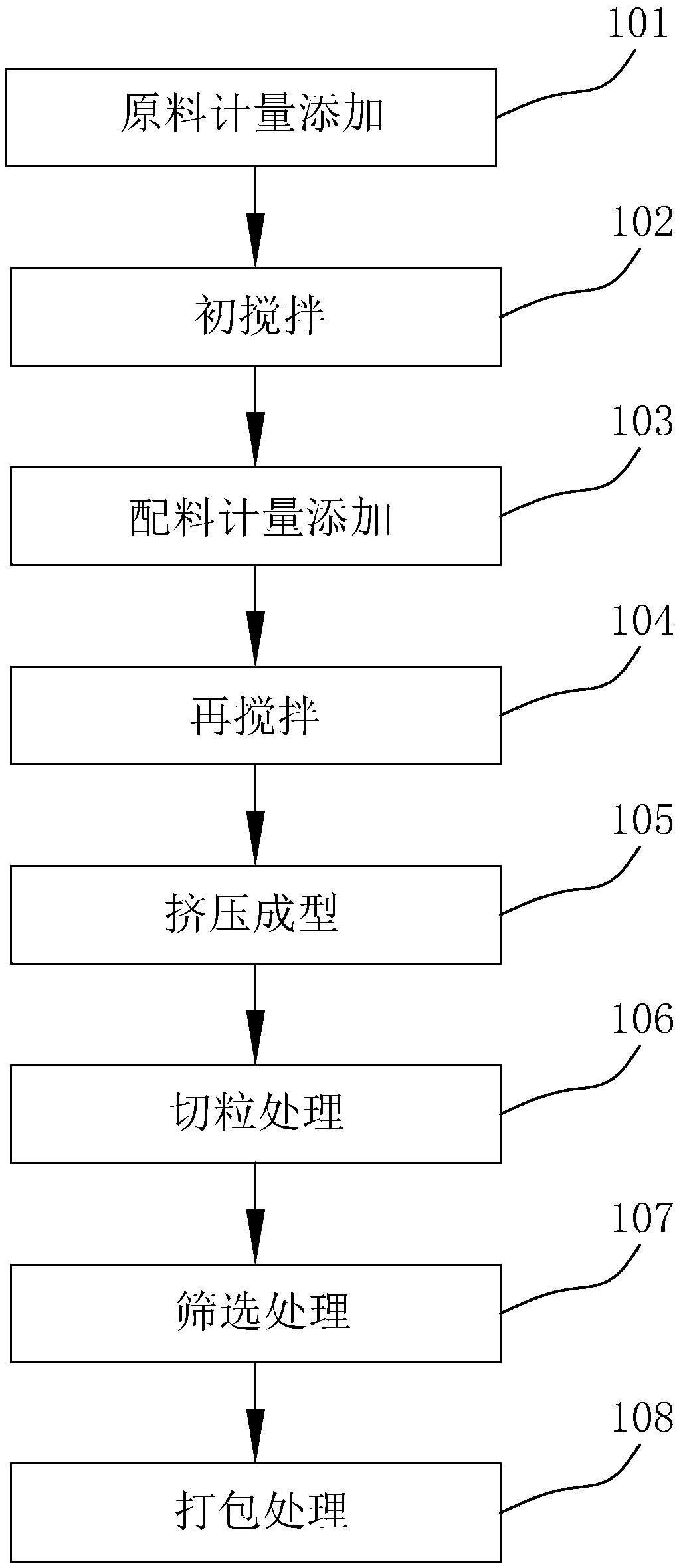

[0071] A production method of recycled high-impact polystyrene material, combiningfigure 1 and figure 2 As shown, on the basis of the recycled high-impact polystyrene material production system described in Example 1, the production method includes the following steps: raw material metering 101, initial stirring 102, ingredient metering 103, re-stirring 104, Extrusion molding 105, pelletizing treatment 106, screening treatment 107 and packaging treatment 108.

[0072] Raw material metering and adding 101: add high-impact polystyrene materials or recycled polystyrene materials to the automatic weighing feeding mechanism 11, weigh the weight of each raw material through the automatic weighing feeding mechanism 11, and feed it to the mixer according to the preset ratio In 2, high-impact polystyrene materials and recycled polystyrene materials are added.

[0073] Initial stirring 102: Preliminary stirring is performed on the high-impact polystyrene material and the recycled poly...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com