Combined denitrification method and device for sludge thermal hydrolysis anaerobic digestion biogas slurry

A technology of anaerobic digestion and thermal hydrolysis, applied in chemical instruments and methods, water/sludge/sewage treatment, biological sludge treatment, etc., can solve problems such as inability to process biogas slurry, and achieve risk enhancement and total nitrogen removal. The effect of increasing the rate and stable operation of the system

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

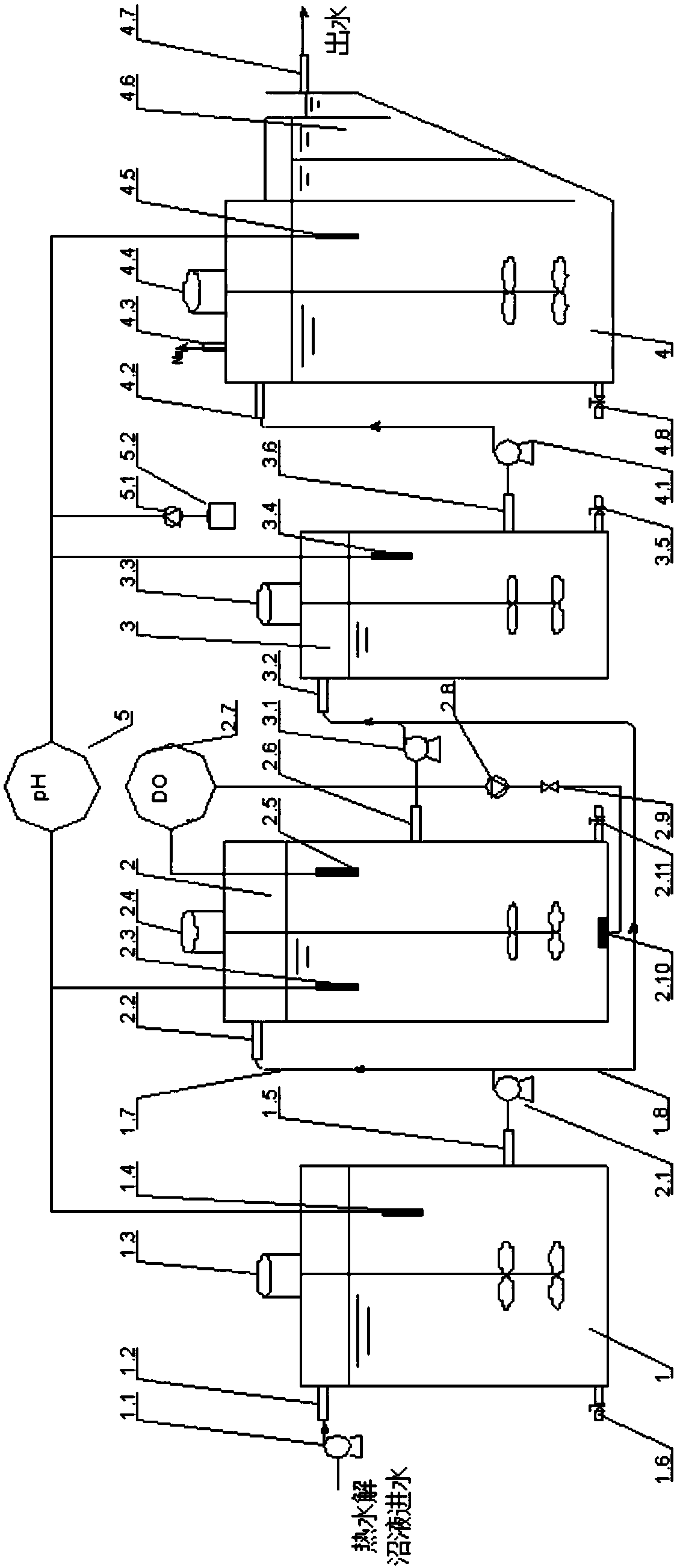

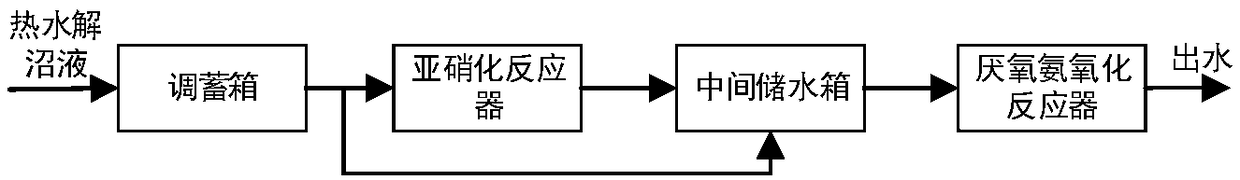

[0052] In this embodiment, the structure of the device used in the combined denitrification method of sludge thermal hydrolysis anaerobic digestion biogas slurry is as follows figure 1 As shown, it includes thermal hydrolysis biogas slurry storage tank 1, nitrosation reactor 2, intermediate water storage tank 3, anaerobic ammonium oxidation reactor connected in sequence,

[0053] The upper part of the thermal hydrolysis biogas slurry storage tank 1 is provided with a water inlet 1.2 of the thermal hydrolysis biogas slurry storage tank, and the water inlet 1.2 of the thermal hydrolysis biogas slurry storage tank is connected to the original biogas slurry delivery pump 1.1. Biogas slurry storage tank mixer 1.3 is fixed on the top of the storage tank with a bracket, pH online measuring instrument 1.4 is suspended and fixed at 1 / 2 of the height of the storage tank, and the bottom is equipped with an emptying pipe and mud discharge pipe 1.6, the height of the storage tank The outle...

Embodiment 2

[0069] The device used in the combined denitrification method of sludge thermal hydrolysis anaerobic digestion biogas slurry in this example is the same as that in Example 1.

[0070] The experimental water used in this example is taken from the plate and frame press filtrate after thermal hydrolysis and anaerobic digestion of sludge from a sludge plant in Changsha City, Hunan Province. The water quality is as follows: NH 4 + -N: 1500; COD: 2000; SS: 100mg / L; Alkalinity: 2000mg / L; pH 7.5.

[0071] The combined denitrification method of anaerobic digestion biogas slurry by thermal hydrolysis of sludge specifically includes the following steps:

[0072] (1) Pretreatment of sludge thermal hydrolysis anaerobic digestion biogas slurry

[0073] The thermal hydrolysis biogas slurry storage tank 1 in the device pretreats the raw biogas slurry, using NaHCO 3 and HCl to adjust the pH of the raw biogas slurry to 7.5, using NaHCO 3 Adjust biogas slurry alkalinity to 4500mgCaCO 3 / L, ...

Embodiment 3

[0081] The device used in the combined denitrification method of sludge thermal hydrolysis and anaerobic digestion biogas slurry in this example is the same as that in Example 1.

[0082] The experimental water used in this example is taken from the plate and frame press filtrate after thermal hydrolysis and anaerobic digestion of sludge from a sludge plant in Changsha City, Hunan Province. The water quality is as follows: NH 4 + -N: 1600; COD: 2200; SS: 200mg / L; alkalinity: 3000mg / L; pH value 8.0.

[0083] The combined denitrification method of anaerobic digestion biogas slurry by thermal hydrolysis of sludge specifically includes the following steps:

[0084] (1) Pretreatment of sludge thermal hydrolysis anaerobic digestion biogas slurry

[0085] The thermal hydrolysis biogas slurry storage tank 1 in the device pretreats the raw biogas slurry, using NaHCO 3 and HCl to adjust the pH of the raw biogas slurry to 8, using NaHCO 3 Adjust biogas slurry alkalinity to 5500mgCaCO...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com