Reactor for implementing static cultivation and continuous growth of aerobic filamentous biological membranes

A static culture and biofilm technology, applied in biological treatment devices, sustainable biological treatment, biological water/sewage treatment, etc., can solve the problem of long-term continuous and stable operation of reactors, unsustainable and stable growth, and microbial biofilm Avoid problems such as shedding, and achieve the effects of avoiding aging and death, promoting continuous growth, and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

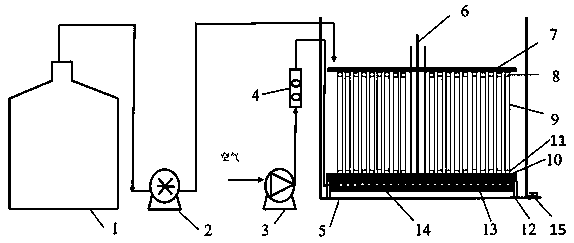

[0023] A reactor for static culture and continuous growth of aerobic filamentous biofilms, such as figure 1 As shown, it includes a feed tank 1, a peristaltic pump 2, an aeration pump 3, a gas flow meter 4, a reaction tank 5, a carrier bracket 6, an upper partition 7, an upper conduit 8, a vessel carrier 9, a lower partition 10, Downpipe 11, support 12, microporous aeration pipe 13, enclosure 14, drain 15;

[0024] The carrier bracket 6, the upper partition 7, the upper conduit 8, the vessel carrier 9, the lower partition 10, the lower conduit 11, the support 12, the microporous aeration tube 13, and the enclosure 14 are arranged inside the reaction tank 5, and the upper partition The plate 7 and the lower partition 10 are respectively arranged on the upper and lower parts of the carrier bracket 6, and 80 vessel carriers 9 are arranged between the upper partition 7 and the lower partition 10, and the vessel carriers 9 are silk hook and loop, and the upper The partition board ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com