Conditioning agent for sludge solidification and preparing method and application thereof

A technology of conditioner and sludge, which is applied in the field of conditioner for sludge solidification and its preparation and application, and can solve the problems of long use time, ineffective treatment and disposal of heavy metals in sludge, secondary pollution, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

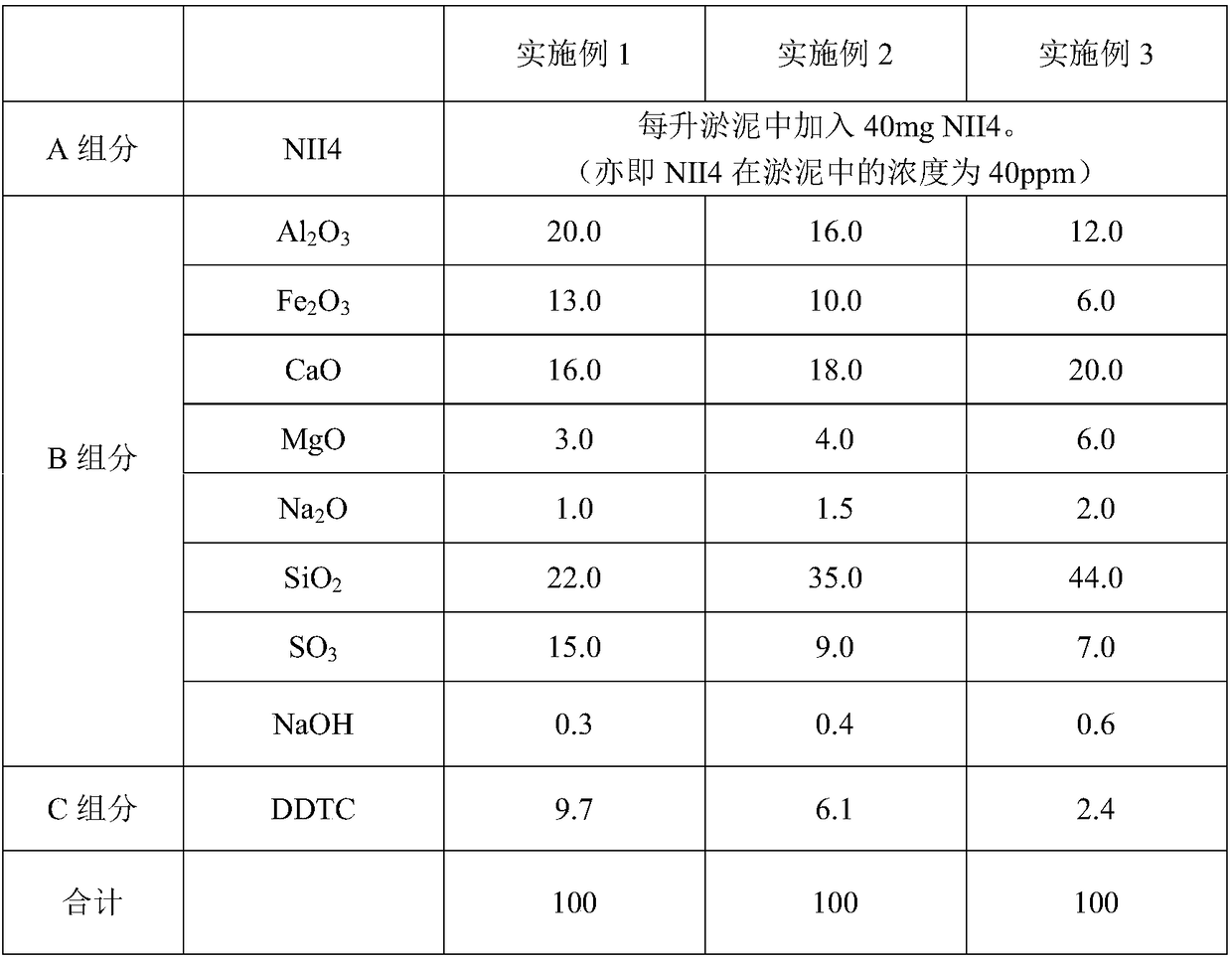

[0027] Table 1 is the raw materials and proportioning used in Examples 1 to 3 of the present invention.

[0028] Table 1 Raw materials used in each embodiment and proportioning unit: %

[0029]

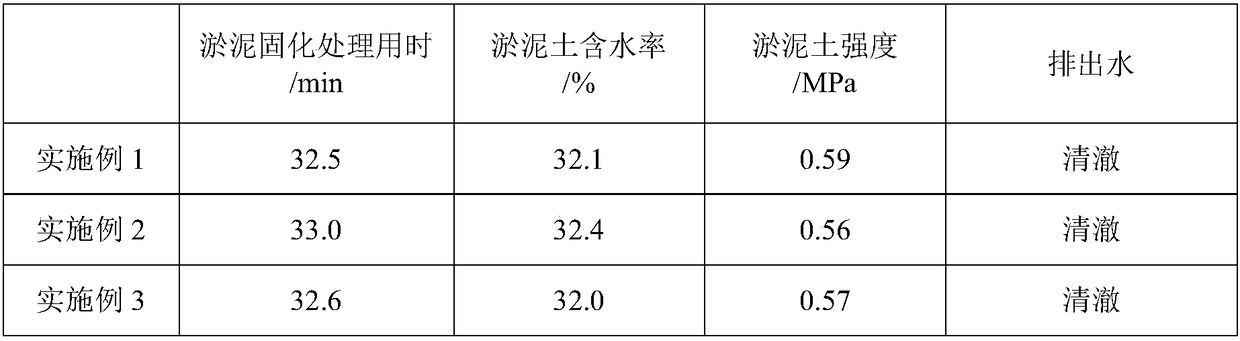

[0030] Table 2. is according to Table 1. It is the result of the used raw materials and proportioning of the shown embodiments 1-3 to the sludge solidification treatment.

[0031] Table 2 Results of sludge solidification treatment

[0032]

[0033] The preparation of the A component microbial flocculant NII4 of the above-mentioned embodiment 1-3 of the present invention:

[0034] NII4 was selected as the strain, and the best carbon source: sucrose; the best nitrogen source: yeast extract + urea + (NH 4 ) 2 SO 4 ;Temperature: 30°C; pH 7-8, culture time: 72h.

[0035] Preparation of B component of chemical flocculant:

[0036] 1. Roast metal oxides and non-metal oxides in a roasting furnace at 1150°C for 2 hours;

[0037] 2. The material obtained in step 1 is cooled to room...

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com