Underwater-curable epoxy glass flake coating and preparation method thereof

An epoxy glass, underwater curing technology, applied in the field of coatings, can solve problems such as easy dispersion of underwater construction, high viscosity of curing agent, and multiple diluents, etc. slow effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

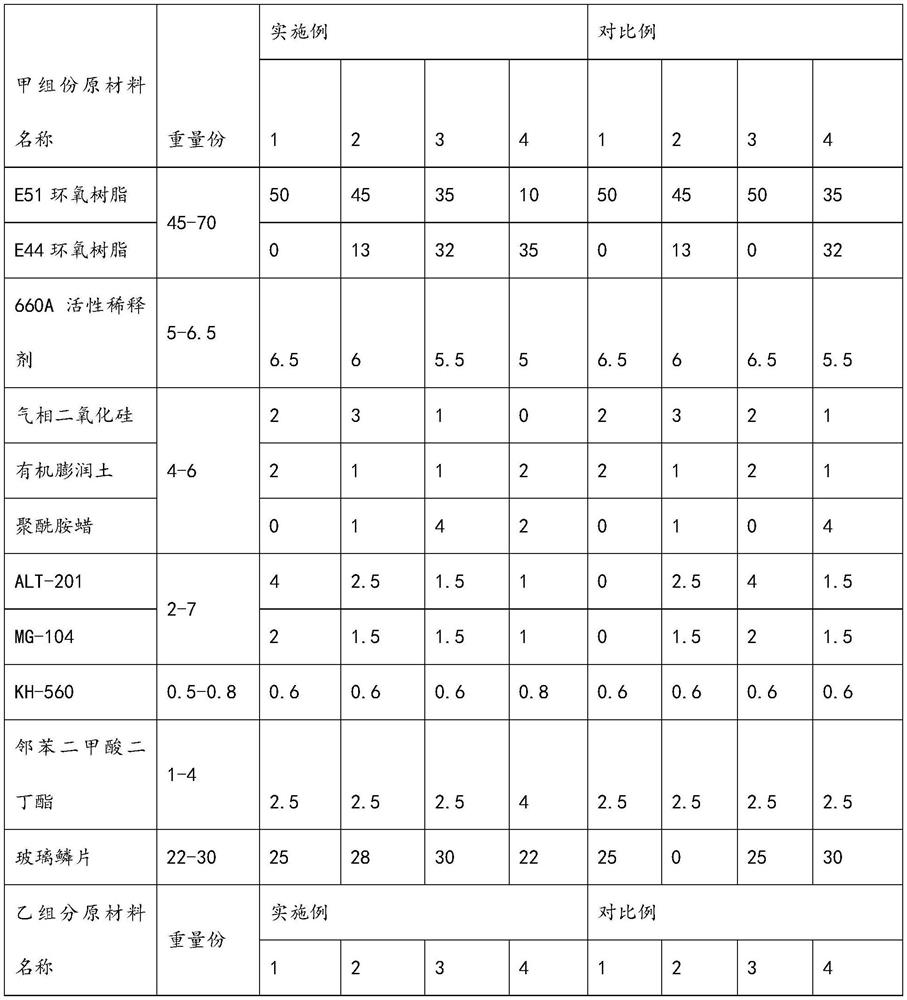

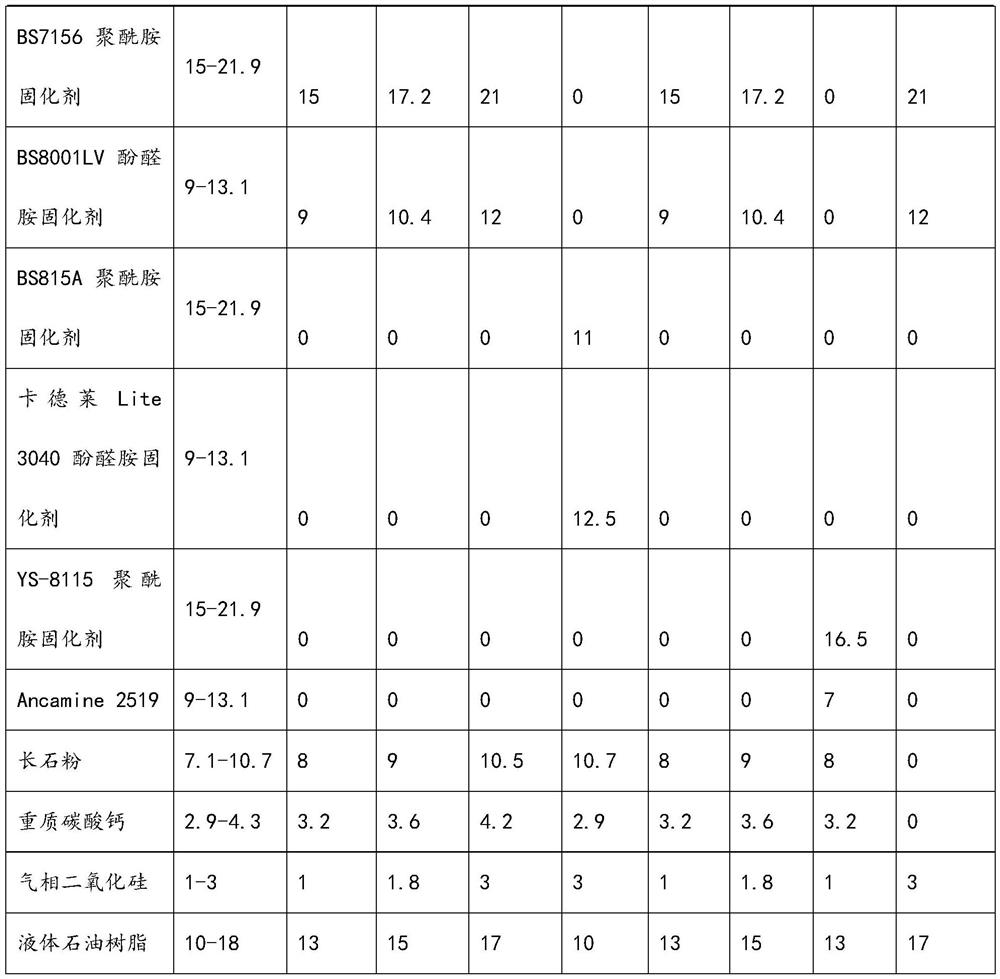

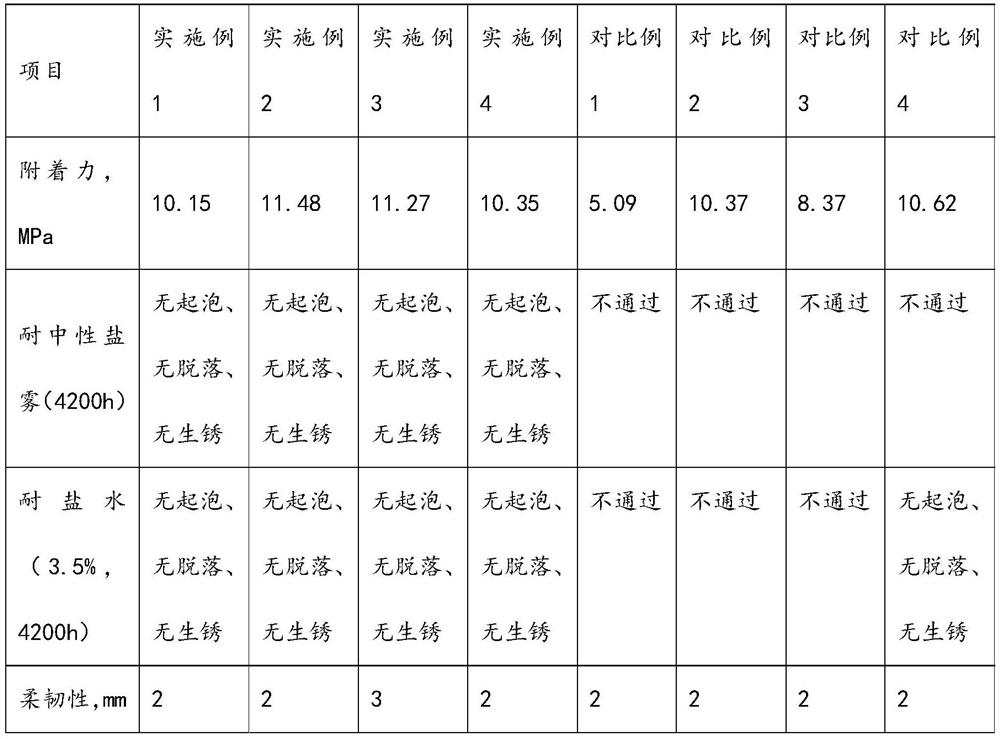

Examples

Embodiment 1

[0043] The bisphenol A epoxy resin is E51 solvent-free epoxy resin.

[0044] The reactive diluent is 660A reactive diluent.

[0045] The water remover is ALT-201 and MG-104.

[0046] The coupling agent is KH-560.

[0047] The glass flakes are C-type glass flakes.

[0048] The curing agent is a solvent-free amine curing agent, wherein the active hydrogen equivalent of BS7156 polyamide curing agent is 145; the active hydrogen equivalent of BS8001LV phenalkamine curing agent is 120.

[0049] The pigment and filler are a mixture of feldspar powder and heavy calcium carbonate.

[0050] The liquid petroleum resin is Lütger LA300.

[0051] Example 1 The mass ratio of component A: component B is 1:1.

Embodiment 2

[0055] The bisphenol A epoxy resin is a solvent-free epoxy resin, including E51 epoxy resin and E44 epoxy resin.

[0056] The reactive diluent is 660A reactive diluent.

[0057] The water remover is ALT-201 and MG-104.

[0058] The coupling agent is KH-560.

[0059] The glass flakes are C-type glass flakes.

[0060] The curing agent is a solvent-free amine curing agent, wherein the active hydrogen equivalent of BS7156 polyamide curing agent is 145; the active hydrogen equivalent of BS8001LV phenalkamine curing agent is 120.

[0061] The pigment and filler are a mixture of feldspar powder and heavy calcium carbonate.

[0062] The liquid petroleum resin is Lütger LA300.

[0063] Example 2 The mass ratio of component A: component B is 1:1.

Embodiment 3

[0066] The bisphenol A epoxy resin is a solvent-free epoxy resin, including E51 epoxy resin and E44 epoxy resin.

[0067] The reactive diluent is 660A reactive diluent.

[0068] The water remover is ALT-201 and MG-104.

[0069] The coupling agent is KH-560.

[0070] The glass flakes are C-type glass flakes.

[0071] The curing agent is a solvent-free amine curing agent, wherein the active hydrogen equivalent of BS7156 polyamide curing agent is 145; the active hydrogen equivalent of BS8001LV phenalkamine curing agent is 120.

[0072] The pigment and filler are a mixture of feldspar powder and heavy calcium carbonate.

[0073] The liquid petroleum resin is Lütger LA300.

[0074] Example 3 The mass ratio of component A: component B is 1:1.

[0075] In Comparative Example 4, except that no pigments and fillers were added, the components used were the same as in Example 3, the preparation method was the same as in Example 3, and the mass ratio of component A and component B wa...

PUM

| Property | Measurement | Unit |

|---|---|---|

| viscosity | aaaaa | aaaaa |

| viscosity | aaaaa | aaaaa |

| viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com