Patents

Literature

41 results about "T-butyl formate" patented technology

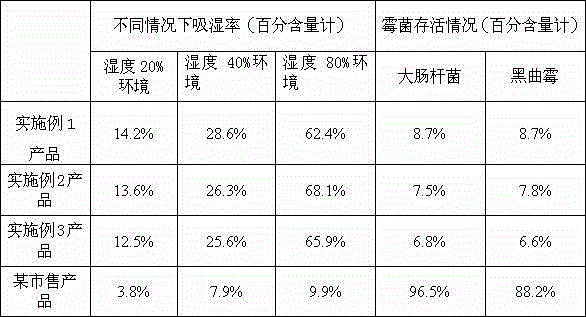

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Tert-Butyl formate, also known as formic acid tert-butylester and TBF, is a chemical compound with molecular formula C 5 H 10 O 2. TBF is one of the possible daughter products of methyl tert -butyl ether biodegradation .

Cosmetic formulation

Disclosed is a topical skin cleanser comprising Silybum marianum fruit extract, Momordica grosvenorii fruit extract, and a cosmetic vehicle comprising at least 50% by weight of the composition of water and disodium EDTA, glycerin, phenoxyethanol, triethanolamine, 3-Iodo-2-propynyl butyl carbamate, and benzyl alcohol.

Owner:MARY KAY INC

Cosmetic formulation

ActiveUS20130209504A1Avoid significant dripping or poolingBiocideCosmetic preparationsMedicineIodine

Disclosed is a topical skin cleanser comprising Silybum marianum fruit extract, Momordica grosvenorii fruit extract, and a cosmetic vehicle comprising at least 50% by weight of the composition of water and disodium EDTA, glycerin, phenoxyethanol, triethanolamine, 3-Iodo-2-propynyl butyl carbamate, and benzyl alcohol.

Owner:MARY KAY INC

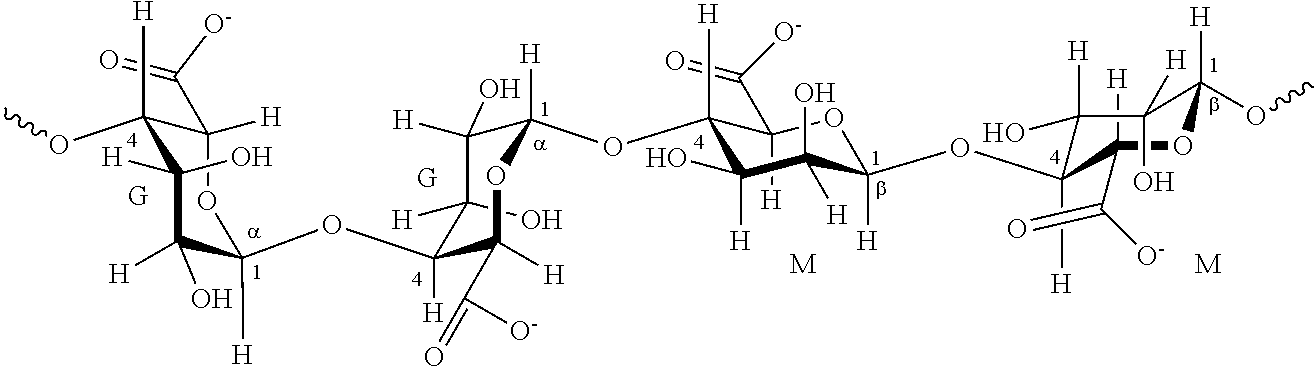

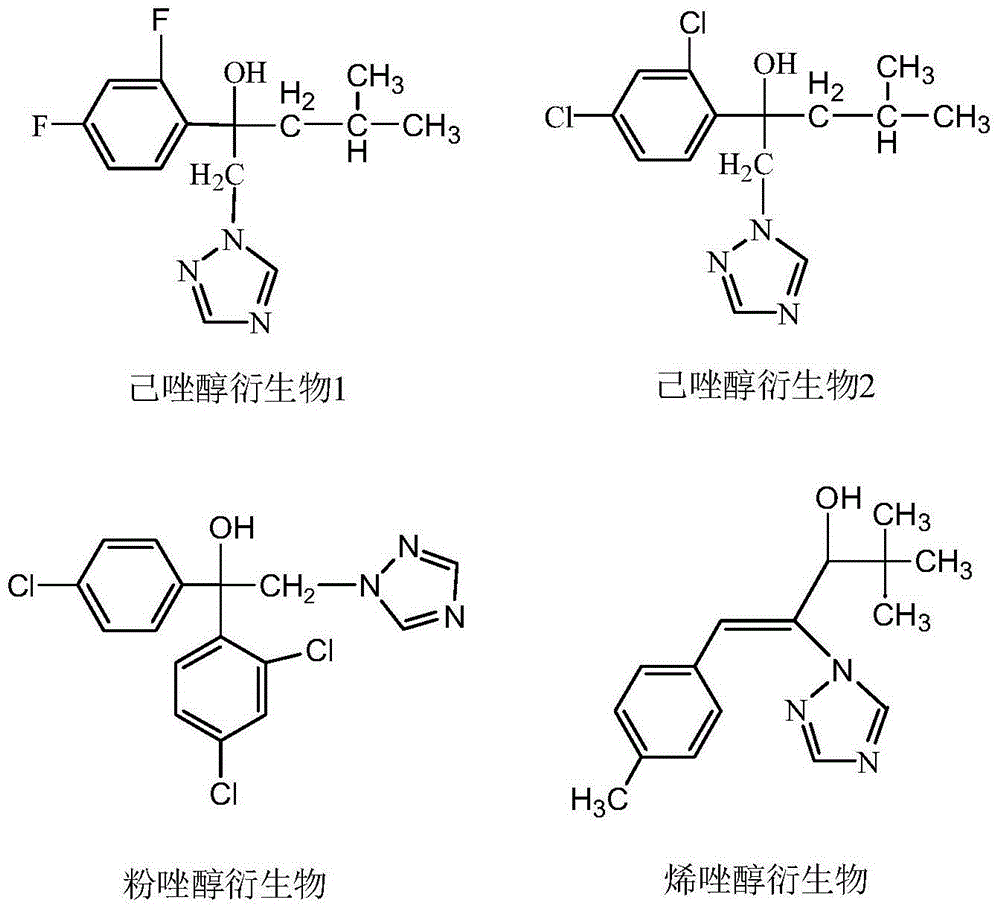

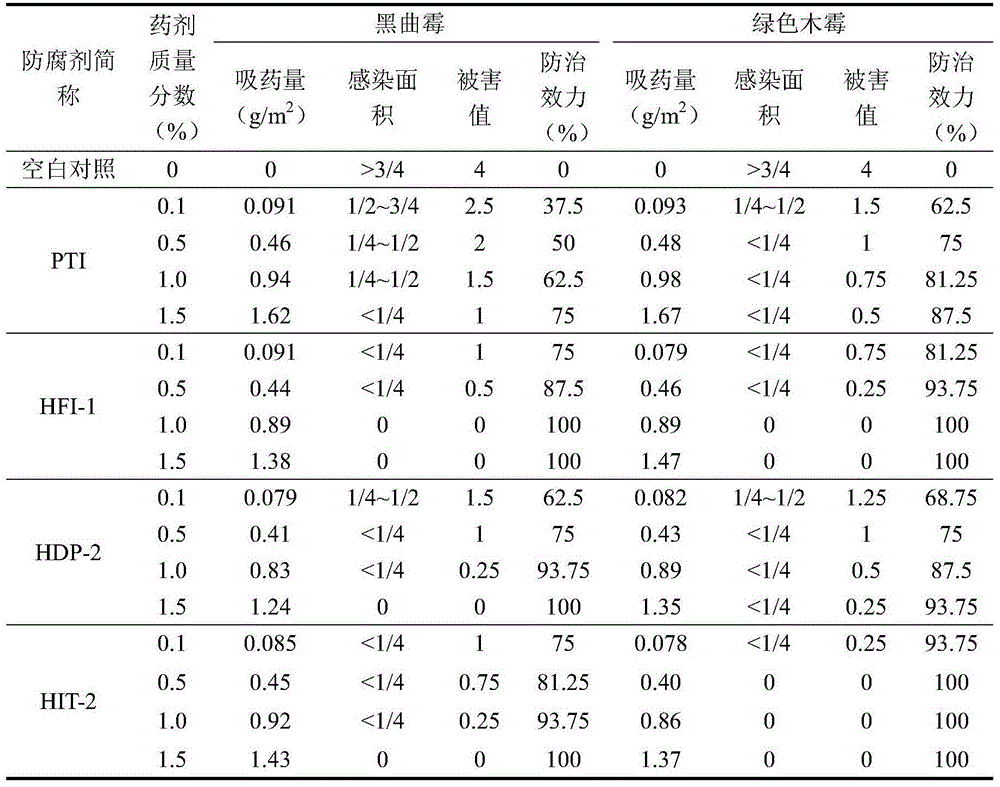

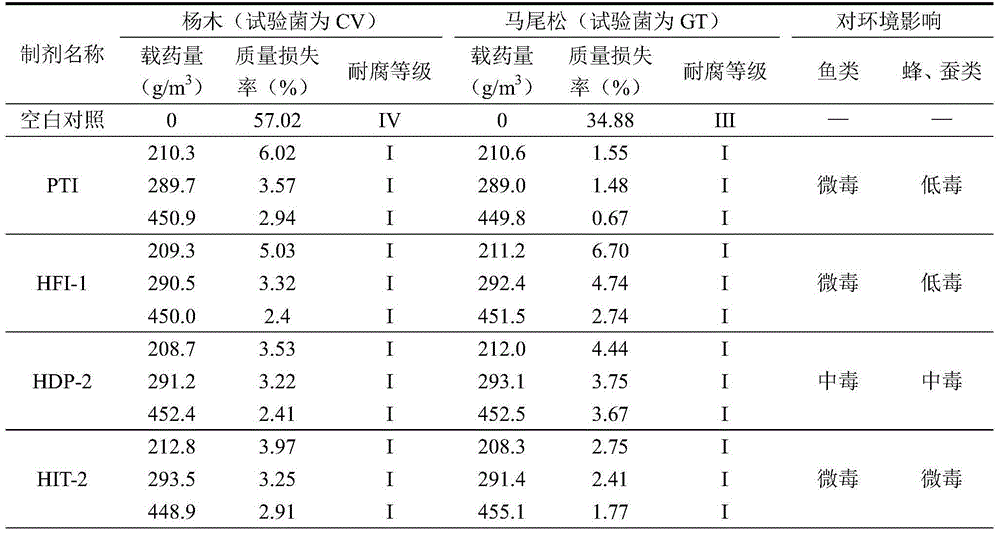

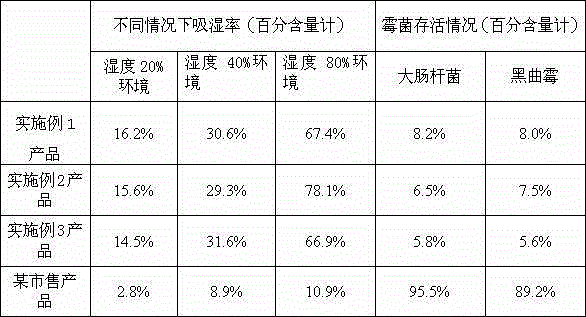

Water-borne composite organic wood preservative, preparation method and application thereof

The invention relates to a water-borne composite organic wood preservative, a preparation method and application thereof. The wood preservative comprises the following components by mass: 5-15% of an organic insecticide and bactericide, 25-40% of an organic solvent, 15-20% of a surfactant, and the balance water. The organic insecticide and bactericide is at least one of a triazole compound, 3-iodo-2-propynyl-butyl-carbamate (called IPBC for short), imidacloprid and pyrethroid substances. The organic solvent is at least one of cyclohexanone, dimethylformamide (DMF), and xylene. The wood preservative provided by the invention has good antiseptic and mould proof effects, low dosage, good loss resistance and environmental friendliness, and can be widely used in indoor furniture, indoor decoration materials, outdoor gardens, constructions and the like.

Owner:NANJING FORESTRY UNIV

Water-based paint for pipeline and preparing method of water-based paint

InactiveCN105255332ACorrosionStrong adhesionAntifouling/underwater paintsPaints with biocidesSODIUM METAPHOSPHATEMelamine phosphate

The invention relates to water-based paint for a pipeline. The water-based paint for the pipeline is prepared from modified phenolic resin, pitch, alcohol acid emulsion, chromium oxide green, an anti-rusting agent, low polymer polyhydric alcohols, maleic anhydride, methyl methacrylate, hydroxyl ethyl acrylate, hydroxylated fiber resin, polyether sulfone resin, polysorbate, sodium hexametaphosphate, organic silicon emulsion, epoxy silane modified silicon sol, crosslinked polyethylene, tert-butyl peroxybenzoate, sodium silicate, melamine phosphate, pentaerythritol, aluminum silicate fibers, silicon dioxide, antibacterial preservative, titanium dioxide, Ni, Zn, water and other raw materials. Due to the fact that the ingredients such as Ni and Zn are contained in the water-based paint for the pipeline, the water-based paint for the pipeline has the high-temperature resisting and corrosion resisting performance, is suitable for coating demands of various occasions, does not contain toxic organic solvents, is free of pollution and has the advantages that a paint surface cannot crack, and the paint is resistant to aging, high in adhesive force and the like.

Owner:ENG EQUIP CO LTD SUZHOU SAI SIDE

Novel disinfection liquid for wet tissue and preparation method for disinfection cotton wet tissue

InactiveCN103583515AImprove water absorptionGood flexibilityAntibacterial agentsCosmetic preparationsBenzoic acidHuman skin

The invention discloses a novel disinfection liquid for a wet tissue and a preparation method for a disinfection cotton wet tissue. The novel disinfection liquid for the wet tissue comprises the following components in percentage by weight: 92.1-98.3 percent of deionized water, 1.0-5.0 percent of propylene glycol, 0.05-0.2 percent of essence, 0.7-1.8 percent of alkyl glucosides, 0.2-0.5 percent of a eucalyptus leaf extracting solution, 0.3-0.5 percent of an aloe extracting solution, 0.5-1.5 percent of methyl parahydroxybenzoats and 0.05-0.2 percent of iodo-propinyl butyl carbamate. The novel disinfection liquid has a wide application range and is convenient to carry; due to the iodo-propinyl butyl carbamate serving as a cleaning component and the alkyl glucosides, aloe, eucalyptus leaves and the like which serve as moistening components, the novel disinfection liquid has a mild nature, can protect the skin and is low in residue content; furthermore, blots on the skin of a human body can be effectively removed, and the novel disinfection liquid is suitable for families with high requirements on cleanness.

Owner:SHANGHAI UNIV

Water-based exterior wall coating and preparation method thereof

InactiveCN105219221AStrong adhesionImprove adhesionAntifouling/underwater paintsConjugated diene hydrocarbon coatingsSODIUM METAPHOSPHATEBenzoic acid

The invention discloses a water-based exterior wall coating. The water-based exterior wall coating is prepared from the following raw materials: a butadiene styrene rubber emulsion, polyamide, kaolin powder, a flatting agent, lignocelluloses, magnesium phosphate, polysiloxane, glass fiber, aluminum silicate fiber, hydroxylation fiber resin, polyether sulfone resin, polysorbate, sodium hexametaphosphate, an organic silicone emulsion, an epoxy silane modified silicone sol, cross-linked polyethylene, butyl peroxybenzoate, sodium silicate, melamine polyphosphate, pentaerythritol, silicon dioxide, a sterilization preservative, a film-forming aid, waterborne polyurethane resin, acrylate, tung oil, polyvinyl alcohol, light calcium carbonate, talcum powder, gypsum powder, titanium dioxide, fluororesin, Ni, Zn and water. The water-based exterior wall coating contains the components such as Ni and Zn, so that the water-based exterior wall coating has high temperature resistance and corrosion resistance, meets the coating requirements of various places, is free of toxic organic solvents and free of pollution, and has the advantages of no crack on a coating surface and high adhesion.

Owner:ENG EQUIP CO LTD SUZHOU SAI SIDE

Preparation of leather composite bactericidal mould inhibitor

The invention is a leather composite bactericidal mould inhibitor, and especially is the preparation of the leather composite bactericidal mould inhibitor by using quaternary ammonium salt compounds, 2-bromo-2-nitro-1,3-propanediol, iodo propynyl butylcarbamate, trilon B, a corrosion inhibitor, ethanol and water; the leather composite bactericidal mould inhibitor of the invention comprises the following components by mass: 1%-10% of quaternary ammonium salt compounds, 0.05%-3% of trilon B, 0.1-2% of 2-bromo-2-nitro-1,3-propanediol, 1%-50% of ethanol, 0.05%-5% of iodo propynyl butylcarbamate, 0.1%-20% of corrosion inhibitors, and the balance of water. The purpose of the invention is to provide the preparation of the leather composite bactericidal mould inhibitor, and the preparation comprises the following steps: mixing the quaternary ammonium salt compounds, 2-bromo-2-nitro-1,3-propanediol, and trilon B according to the mass percents with water which accounts for 50% of the balance of water, stirring for 3 hours to prepare a mixed substance A; mixing iodo propynyl butylcarbamate, the corrosion inhibitor, and ethanol according to the mass percents with the rest of water, stirring for 3 hours to prepare a mixed substance B; stirring the mixed substance A and the mixed substance B for reaction for 2 hours, allowing the mixture to stand for 2 hours, performing content determination of the mixed mixture, packaging the qualified mixture to obtain a qualified product. The purpose of the invention is also to dilute the leather composite bactericidal mould inhibitor with a dilution proportion of 50-500 times.

Owner:覃终

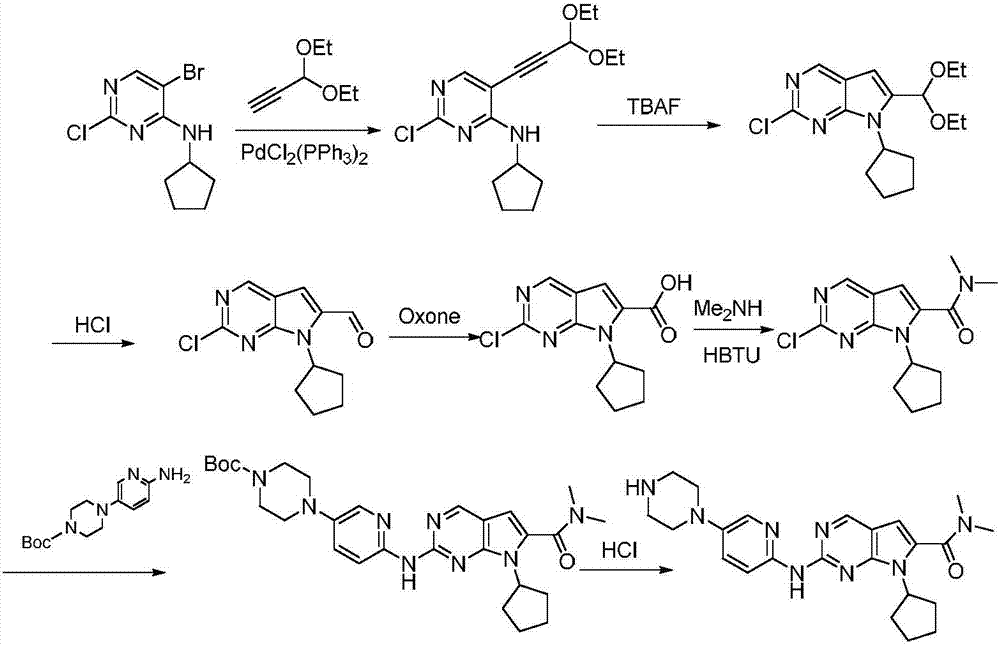

Synthesis technology of ribociclib

The invention discloses a synthesis technology of ribociclib. The synthesis technology comprises the following steps: 1) in the presence of cesium carbonate, 2-chloro-4-cyclopentylaminopyrimidine and 3-bromo-2-oxo-N,N-dimethylpropionamide react under the co-catalysis of cuprous iodide and L-proline to obtain 2-chloro-7-cyclopentyl-N,N-dimethyl-7H-pyrrole[2,3-d]pyrimindine-6-methanamide; and 2) a product obtained in the step 1) and 4-(6-aminopyridine-3-yl)piperazine-1-carboxylic acid tert-butyl ester are subjected to a nucleophilic reaction, and then formic acid-tert-butyl ester is removed under the acidic condition so as to obtain ribociclib. The synthesis technology of the medicine ribociclib for treating breast cancer has advantages of less reaction steps, mild condition and high yield, and is suitable for industrial production.

Owner:山东君瑞医药科技有限公司

Environmentally-friendly water-based paint and preparation method thereof

InactiveCN105176318AStrong adhesionImprove adhesionAntifouling/underwater paintsPaints with biocidesSODIUM METAPHOSPHATESodium phosphates

Environmentally-friendly water-based paint contains hydroxylation fiber resin, polyether sulfone resin, polysorbate, sodium hexametaphosphate, organic silicon emulsion, epoxy group silane modified silica sol, crosslinked polyethylene, tert-butyl peroxybenzoate, sodium silicate, melamine polyphosphate, pentaerythritol, aluminum silicate fibers, silica, hydroxyethyl cellulose, antibacterial preservative, film-forming auxiliaries, waterborne polyurethane resin, acrylic ester, China wood oil, titanium dioxide, polyvinyl alcohol, light calcium carbonate, talcum powder, gypsum powder, titanium dioxide, fluoroethylene resin, waterborne epoxy modified resin, acrylate emulsion, Ni, Zn, water and other raw materials. Because the environmentally-friendly water-base paint contains Ni and Zn, high temperature resistance and corrosion resistance are achieved, coating requirements of kinds of occasions are met, and the paint does not contain toxic organic solvent, is free of pollution and has the advantages that paint coats will not crack, and the paint is resistant to ageing and high in adhesive force.

Owner:ENG EQUIP CO LTD SUZHOU SAI SIDE

Bactericidal, mould-proof and drying agent for calligraphy and painting artworks

InactiveCN105076228AHigh biocidal efficiencyReduce inhibitionBiocideOther chemical processesAbamectinQuinoline

The invention relates to a bactericidal, mould-proof and drying agent for calligraphy and painting artworks. The bactericidal, mould-proof and drying agent comprises the following components in parts by weight: 20-24 parts of ethylene-vinyl acetate copolymer, 22-26 parts of mineral silicon dioxide desiccant powder, 18-22 parts of quartz powder, 22-26 parts of basalt, 18-22 parts of activated carbon, 22-26 parts of refined iron powder, 18-22 parts of agilawood extract, 24-28 parts of guar gum, 18-22 parts of iodopropynyl butylcarbamate, 22-26 parts of cinnamyl aldehyde, 18-22 parts of isothiazolinone, 22-26 parts of mannan oligosaccharide, 18-22 parts of ammonium polyphosphate, 18-22 parts of ethoxyquin, 22-26 parts of sorbic acid, 18-22 parts of pymetrozine, 22-26 parts of ailanthus altissima juice, 18-22 parts of abamectin mixture and 22-26 parts of spinetoram. The preparation technology of the product is simple, and the prepared product has relatively superior bactericidal, mould-proof and drying properties, and is suitable for being used in the field of calligraphy and painting artworks.

Owner:王璐

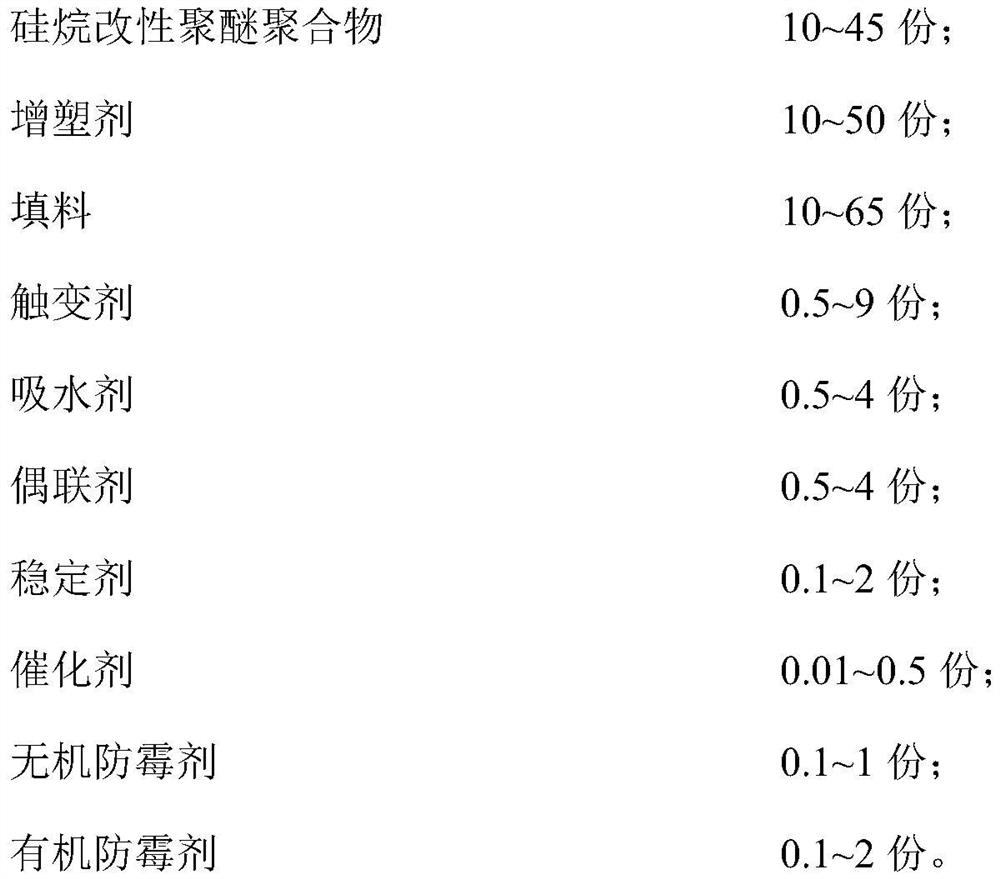

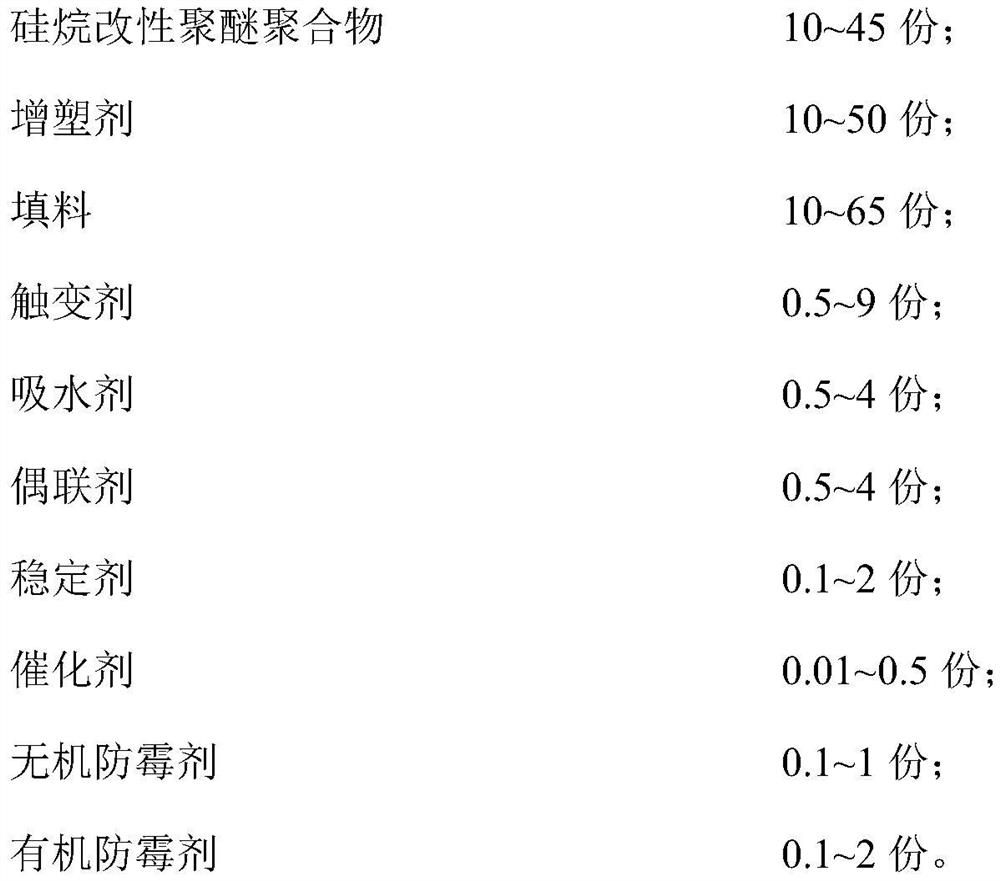

Composite mildew-proof silane modified polyether sealant and preparation method and application thereof

PendingCN112480852AImprove mechanical propertiesEliminate negative effectsNon-macromolecular adhesive additivesPolyether adhesivesIsothiazolinonePolymer science

The invention discloses a composite mildew-proof silane modified polyether sealant and a preparation method and application thereof. The composite mildew-proof silane modified polyether sealant is prepared from the following preparation raw materials: a silane modified polyether polymer, a filler, an auxiliary agent, an inorganic mildew preventive and an organic mildew preventive, wherein the inorganic mildew preventive comprises at least one of nano-zinc oxide and nano-titanium dioxide, and the organic mildew preventive comprises at least one of nitrogenous heterocyclic phenolic alcohol, isothiazolinones, benzisothiazolinone, copper zinc pyrithione and butyl iodopropynylcarbamate. The sealant provided by the invention can achieve the purpose of long-acting mildew prevention, and does notgenerate the problems of discoloration, poor compatibility, influence on shelf life and mechanical properties and the like.

Owner:GUANGZHOU JOINTAS CHEM +1

High-strength environmental-friendly water-based paint and preparation method thereof

InactiveCN105238223AStrong adhesionGood insulation performancePolyurea/polyurethane coatingsEpoxy resin coatingsMagnesium orthophosphateChemistry

The invention relates to a high-strength environmental-friendly water-based paint and a preparation method thereof. The high-strength environmental-friendly water-based paint contains the following raw materials: graphene, hydroxypropyl methyl cellulose, polyamide, magnesium phosphate, fatty acid sorbitan, polysorbate, sodium hexametaphosphate, an silicone emulsion, epoxy based silane modified silica sol, cross-linked polyethylene, peroxide butyl benzoate, sodium silicate, melamine phosphate, n-dodecanethiol, pentaerythritol, aluminum silicate fiber, silica, tetrachloro isophthalonitrile, propylene glycol monomethyl ether, propylene glycol methyl ether acetate, dodecene alcohol ester, water-based polyurethane resin, acrylate, tung oil, titanium dioxide, polyvinyl alcohol, light calcium carbonate, talc powder, titanium dioxide, glass fiber, fluorine resin, waterborne epoxy modified resin, a styrene-acrylic emulsion, a silicone defoaming agent and the like. The high-strength environmental-friendly water-based paint has high temperature resistance and corrosion resistance and can be adapted to the coating requirements of various occasions; furthermore, the high-strength environmental-friendly water-based paint does not contain toxic organic solvent, is pollution-free and has the advantages that a finish coat does not crack, has ageing resistance and strong adhesion force, and the like.

Owner:刘广利

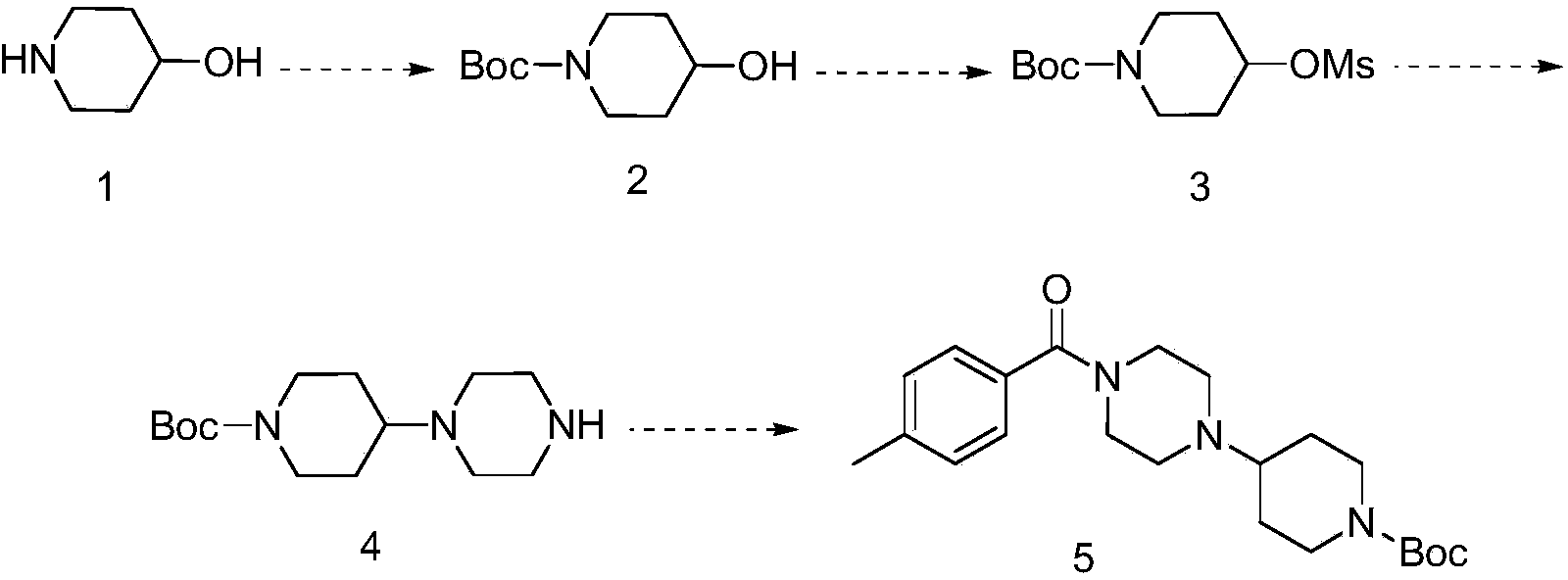

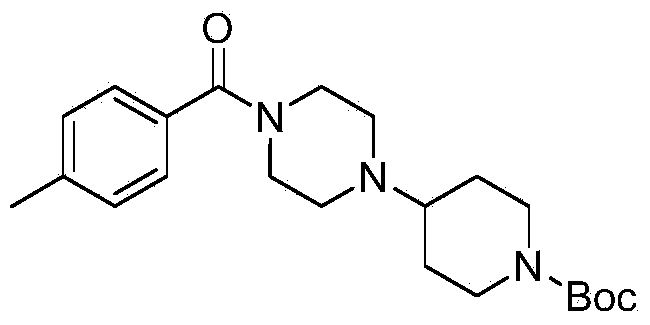

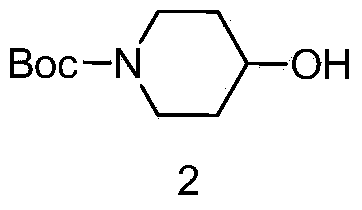

Preparation method of piperazine derivative

InactiveCN104387316AOrganic chemistryBulk chemical productionCombinatorial chemistryNucleophilic substitution

The invention discloses a preparation method of a piperazine (4-(4-methylbenzoyl)piperazine-1-yl)piperidine-1-tert-butoxycarbonyl. The preparation method comprises the steps of, with 4-hydroxypiperazine as a starting material, feeding Boc and performing condensation, nucleophilic substitution and amidation to obtain a target product. The compound is an important medical intermediate.

Owner:湖南华腾制药有限公司

Preparation method of compound leather bactericidal and mildew-proof agent

The invention aims to provide a compound leather bactericidal and mildew-proof agent, and in particular provides a preparation method taking the composition of a guanidine compound, 2-bromo-2-nitro-1,3-propanediol, 3-iodo-2-propynyl butylcarbamate, ethylenediaminetetraacetic acid (EDTA) B, a corrosion inhibitor, ethanol and water as the compound leather bactericidal and mildew-proof agent. The compound leather bactericidal and mildew-proof agent comprises the following components by mass percent: 1-15% of guanidine compound, 0.05-3% of EDTA B, 0.1-2% of 2-bromo-2-nitro-1,3-propanediol, 1-50% of ethanol, 0.05-5% of 3-iodo-2-propynyl butylcarbamate, 0.1-20% of corrosion inhibitor and the balance of water. The preparation method is characterized by comprising the following steps of: mixing the guanidine compound, the 2-bromo-2-nitro-1,3-propanediol and the EDTA B with 50% of water by mass percent, and stirring the mixture for 3 hours to prepare a mixture A; mixing the 3-iodo-2-propynyl butylcarbamate, the corrosion inhibitor and the ethanol with the residual 50% of water by mass percent, and stirring the mixture for 3 hours to prepare a mixture B; and stirring the mixture A and the mixture B to react for 2 hours, then standing for 2 hours, determining the content of the mixture of the mixture A and the mixture B, and packaging the qualified mixture, thus obtaining a qualified product. The invention also aims to dilute the compound leather bactericidal and mildew-proof agent, and the dilution ratio is 50-500 times.

Owner:覃终

Preparation method of compound leather bactericidal and mildew-proof agent

InactiveCN102318634ANot corrosiveNo irritating smellBiocideFungicidesAmmonium compoundsAlcohol ethyl

The invention aims to provide a compound leather bactericidal and mildew-proof agent, and in particular provides a preparation method taking the composition of a guanidine compound, a quaternary ammonium compound, 2-bromo-2-nitro-1,3-propanediol, 3-iodo-2-propynyl butylcarbamate, ethylenediaminetetraacetic acid (EDTA) B, a corrosion inhibitor, ethanol and water as the compound leather bactericidal and mildew-proof agent. The compound leather bactericidal and mildew-proof agent comprises the following components by mass percent: 1-6% of guanidine compound, 1-10% of quaternary ammonium compound, 0.05-3% of EDTA B, 0.1-2% of 2-bromo-2-nitro-1,3-propanediol, 1-50% of ethanol, 0.05-5% of 3-iodo-2-propynyl butylcarbamate, 0.1-20% of corrosion inhibitor and the balance of water. The preparation method is characterized by comprising the following steps of: mixing the guanidine compound, the quaternary ammonium compound, the 2-bromo-2-nitro-1,3-propanediol and the EDTA B with 50% of water by mass percent, and stirring the mixture for 3 hours to prepare a mixture A; mixing the 3-iodo-2-propynyl butylcarbamate, the corrosion inhibitor and the ethanol with the residual 50% of water by mass percent, and stirring the mixture for 3 hours to prepare a mixture B; and stirring the mixture A and the mixture B to react for 2 hours, then standing for 2 hours, determining the content of the mixture of the mixture A and the mixture B, and packaging the qualified mixture, thus obtaining a qualified product. The invention also aims to dilute the compound leather bactericidal and mildew-proof agent, and the dilution ratio is 50-500 times.

Owner:覃终

Matte waterborne coating and preparation method thereof

InactiveCN105219207AStrong adhesionImprove adhesionAntifouling/underwater paintsPaints with biocidesSODIUM METAPHOSPHATEBenzoic acid

The invention discloses a matte waterborne coating. The matte waterborne coating contains low polymer polyol, maleic anhydride, methyl methacrylate, hydroxyl ethyl acrylate, hydroxylation fiber resin, polyether sulfone resin, polysorbate, sodium hexametaphosphate, organic silicon emulsion, epoxy silane modified silica sol, cross-linked polyethylene, butyl peroxybenzoate, sodium silicate, melamine polyphosphate, pentaerythritol, aluminum silicate fiber, silica, hydroxyethyl cellulose, an antibacterial preservative, waterborne polyurethane resin, acrylate, polyvinyl alcohol, light calcium carbonate, titanium dioxide, waterborne epoxy modified resin, Ni, Zn, water and other raw materials. Due to the fact that the matte waterborne coating contains Ni, Zn and other components, the matte waterborne coating has high-temperature resistance and corrosion resistance, meets coating requirements in various occasions, does not contain a toxic organic solvent, is pollution-free, and also has the advantages of no cracking of a paint surface, ageing resistance, strong adhesive force and the like.

Owner:ENG EQUIP CO LTD SUZHOU SAI SIDE

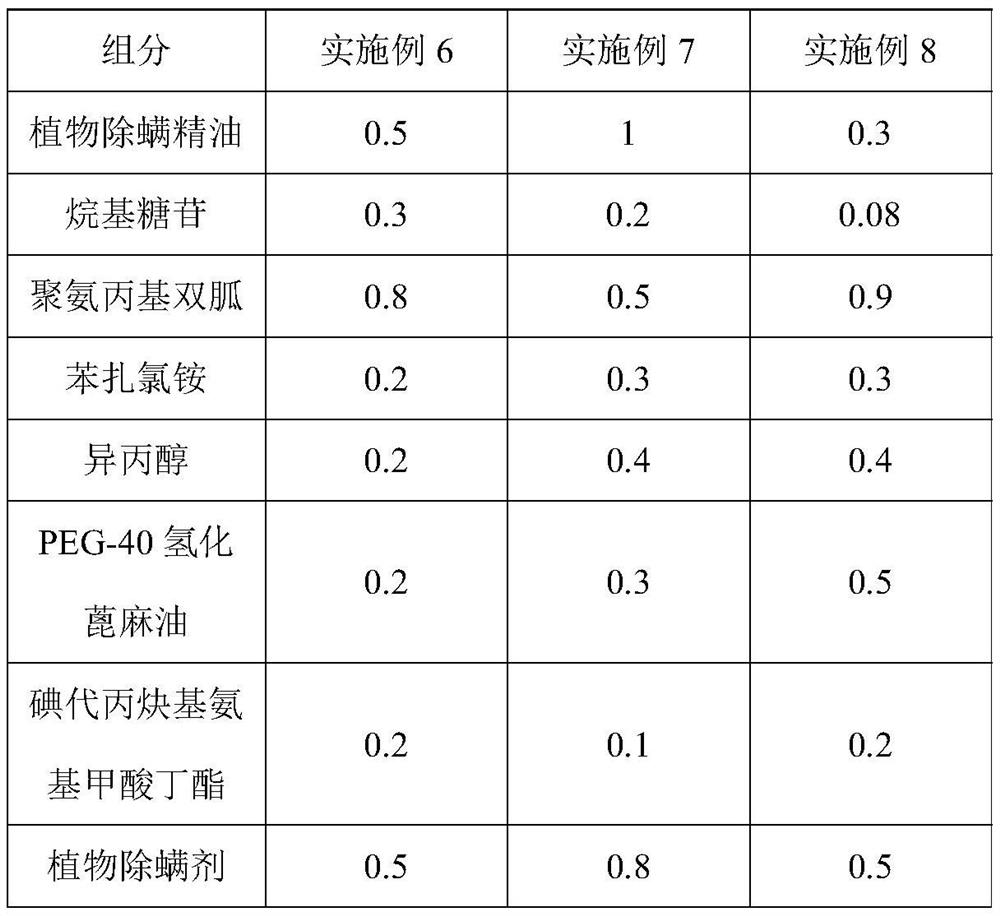

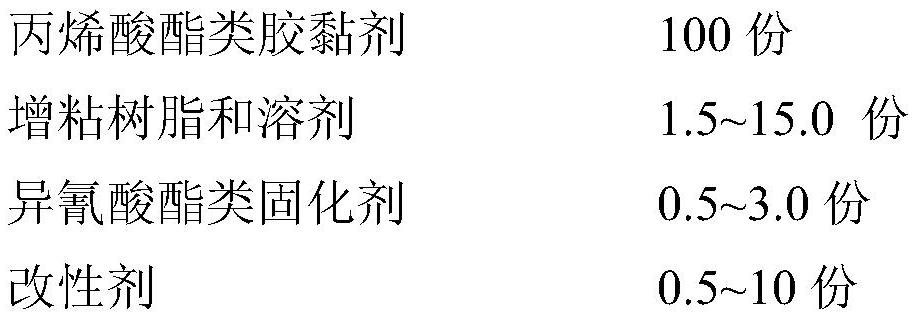

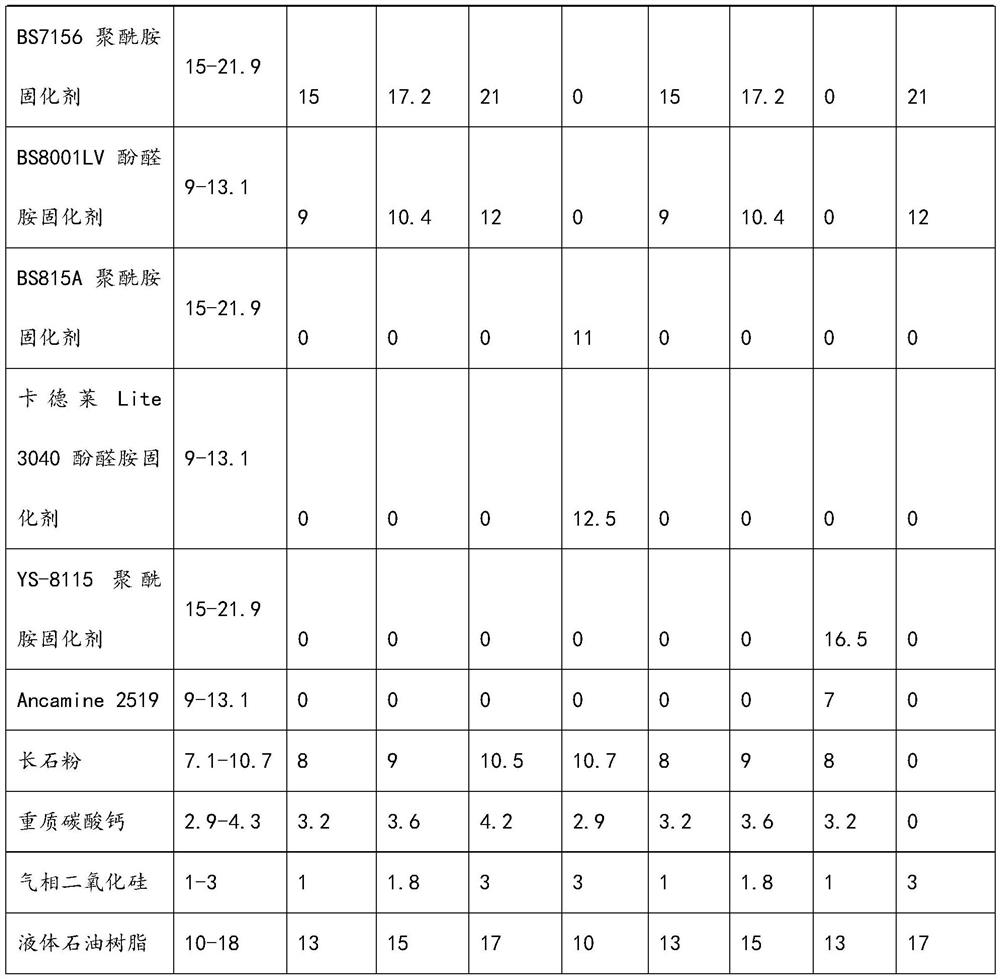

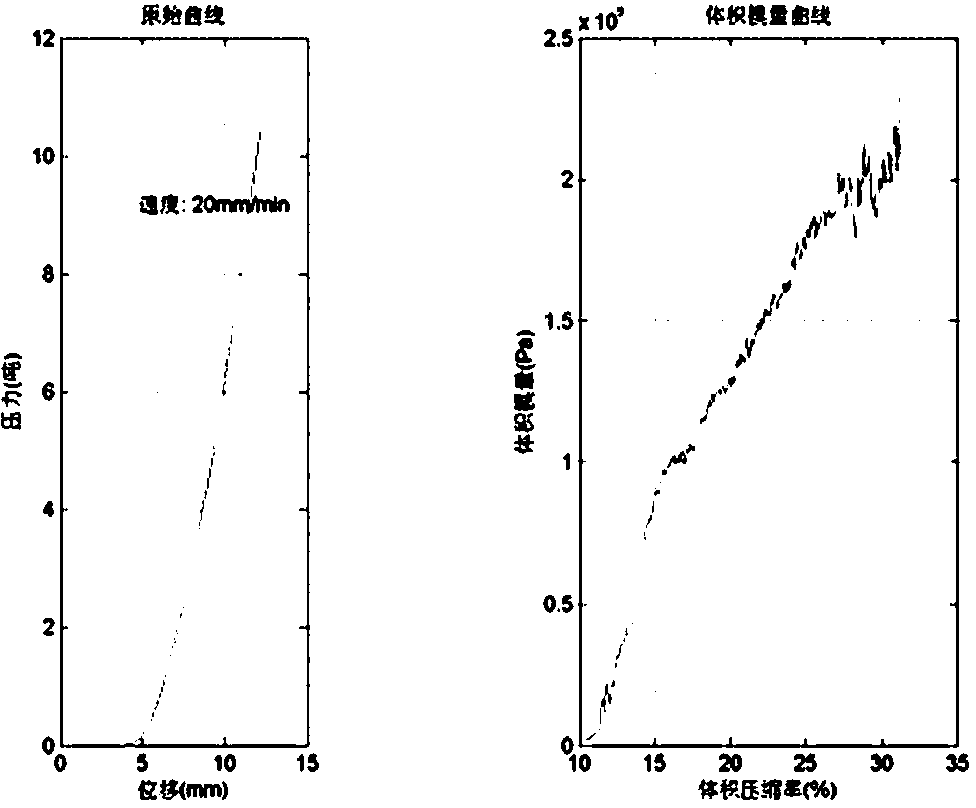

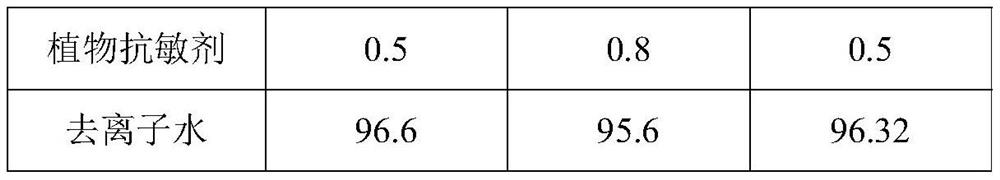

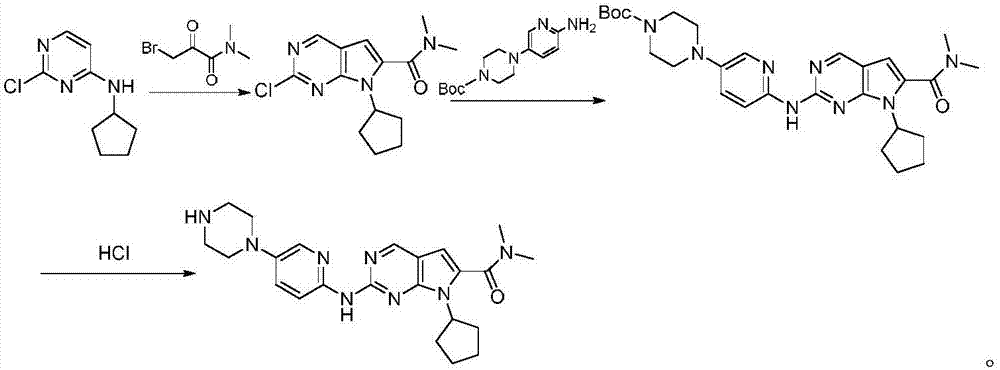

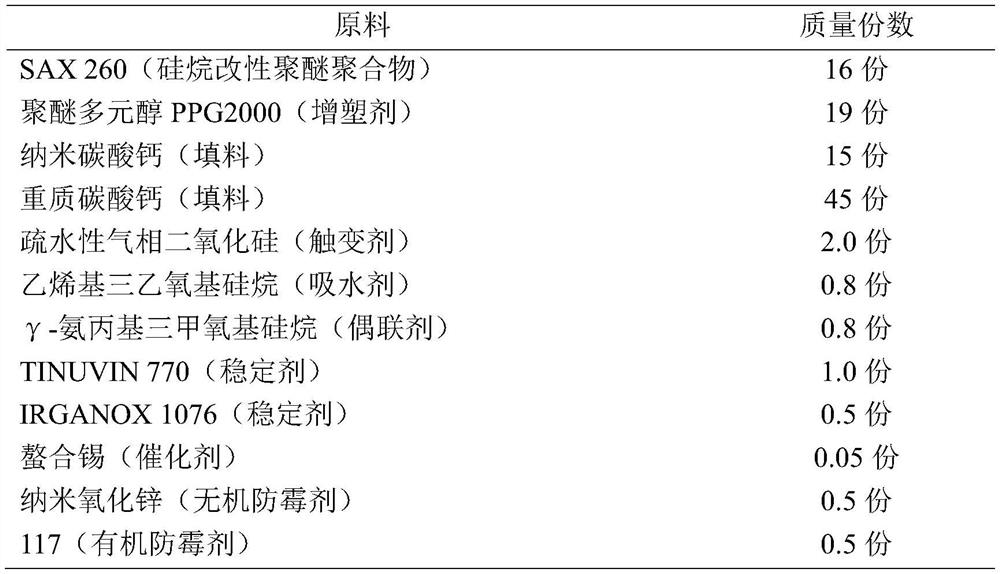

Synthetic method for tert-butyl 1,10-dioxo-2,7-diazaspiro[4.5]decane-7-carboxylate

InactiveCN109608460AReasonable reaction process designHigh yieldOrganic chemistryCarboxylic saltCatalytic effect

The invention relates to a synthetic method for tert-butyl 1,10-dioxo-2,7-diazaspiro[4.5]decane-7-carboxylate, and mainly solves the technical problem that the tert-butyl 1,10-dioxo-2,7-diazaspiro[4.5]decane-7-carboxylate has no synthetic method suitable for industrialization. The synthetic method comprises the following four steps: step 1, dissolving a compound 1 and bromoacetonitrile into anhydrous acetone, and adding potassium carbonate into the above reaction system to obtain a compound 2; step 2, performing a reaction on the compound 2 under the action of sodium borohydride to obtain a compound 3; step 3, introducing hydrogen, and performing ring closing on the compound 3 under the catalytic effect of nickel to obtain a compound 4; and step 4, performing oxidation on the compound 4 toobtain a compound 5, wherein a reaction formula is shown in the description.

Owner:SHANGHAI SYNTHEALL PHARM CO LTD

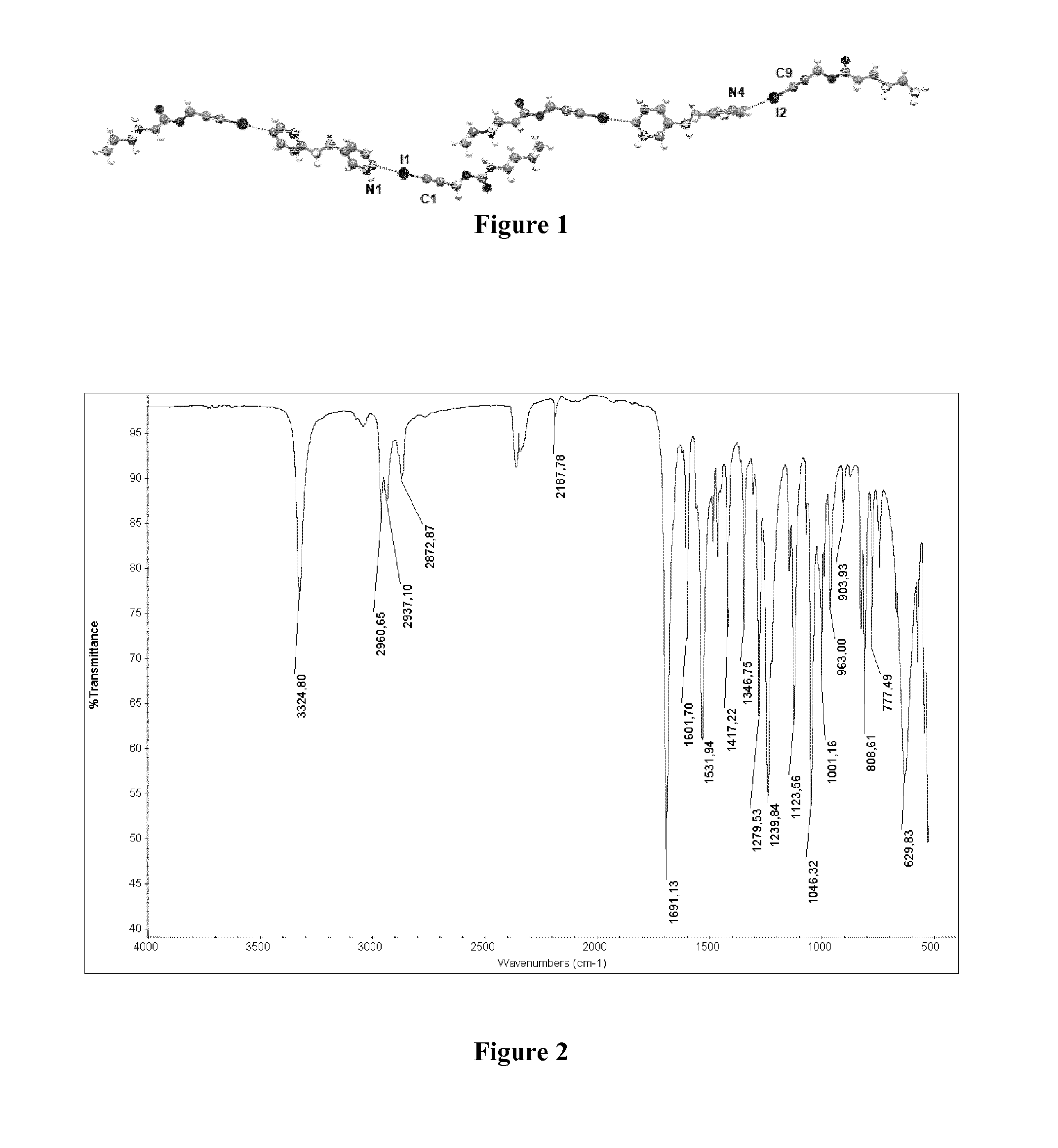

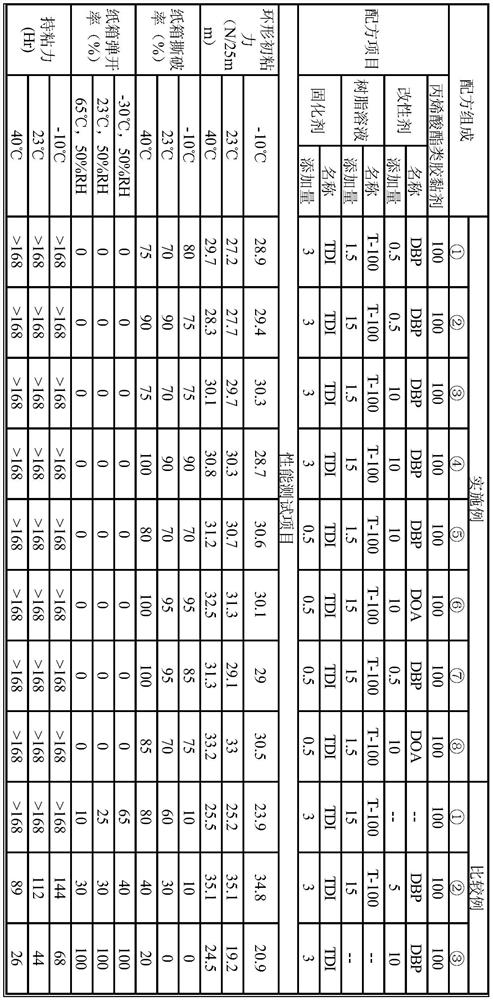

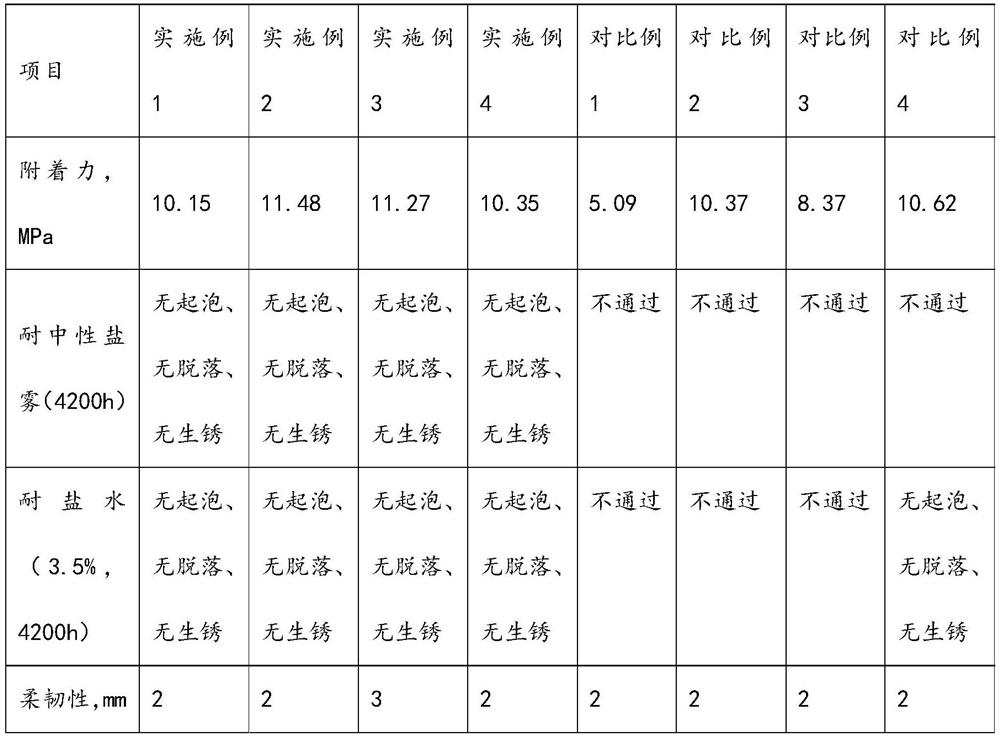

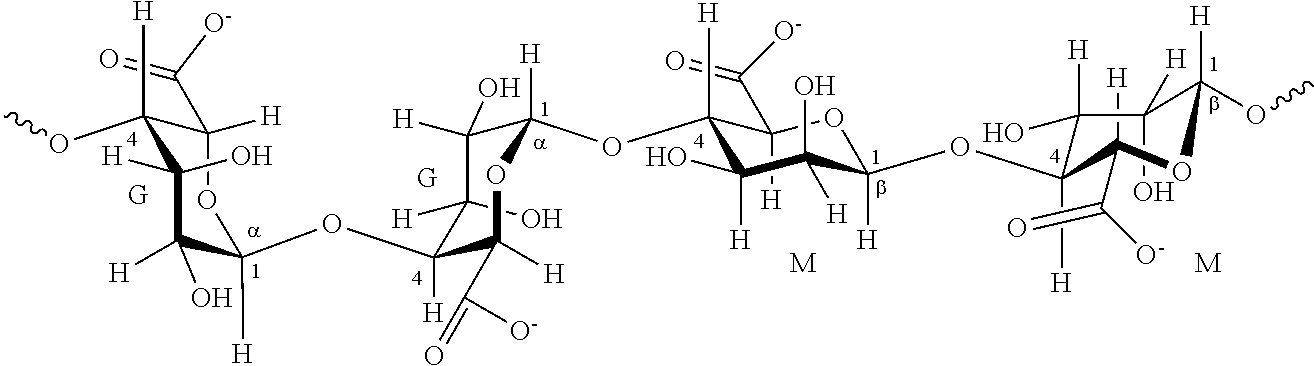

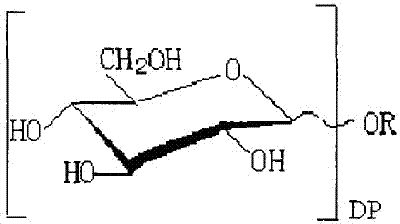

Preparation method of 3-oxymethylene-7-oxa-2,10-diazaspiro[4,6] undecane-10-tert-butyl formate

The invention relates to a synthetic method of 3-oxymethylene-7-oxa-2,10-diazaspiro[4,6] undecane-10-tert-butyl formate and primarily solves the technical problem that no proper industrial synthetic methods are available in the prior art. The method comprises the following three steps: S1, first dissolving a compound 1 in tetrahydrofuran and adding sodium hydride and triethyl phosphonoacetate to carry out a Wittig reaction to obtain a compound 2; S2, dissolving the compound 2, nitromethane and Tetrabutyl ammonium fluoride in tetrahydrofuran and heating the solution to react to generate a compound 3; and S3, dissolving the compound 3 ethanol and carrying out reduction and ring closing by raney nickel to obtain a compound 4; the reaction formula as shown in the description.

Owner:上海药明康德新药开发有限公司

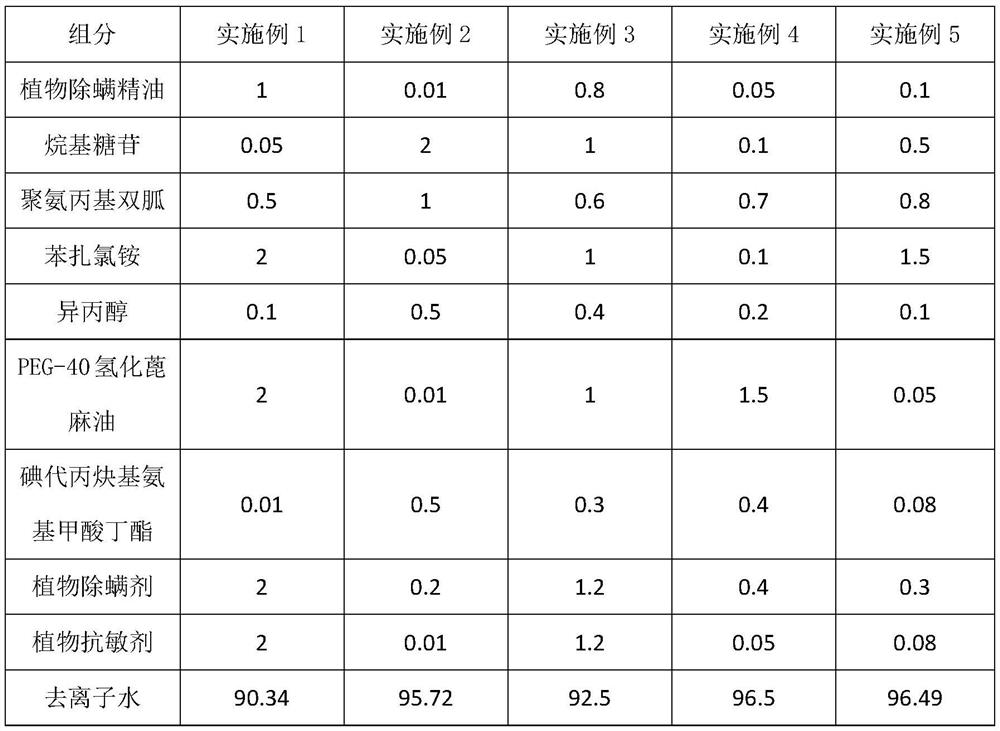

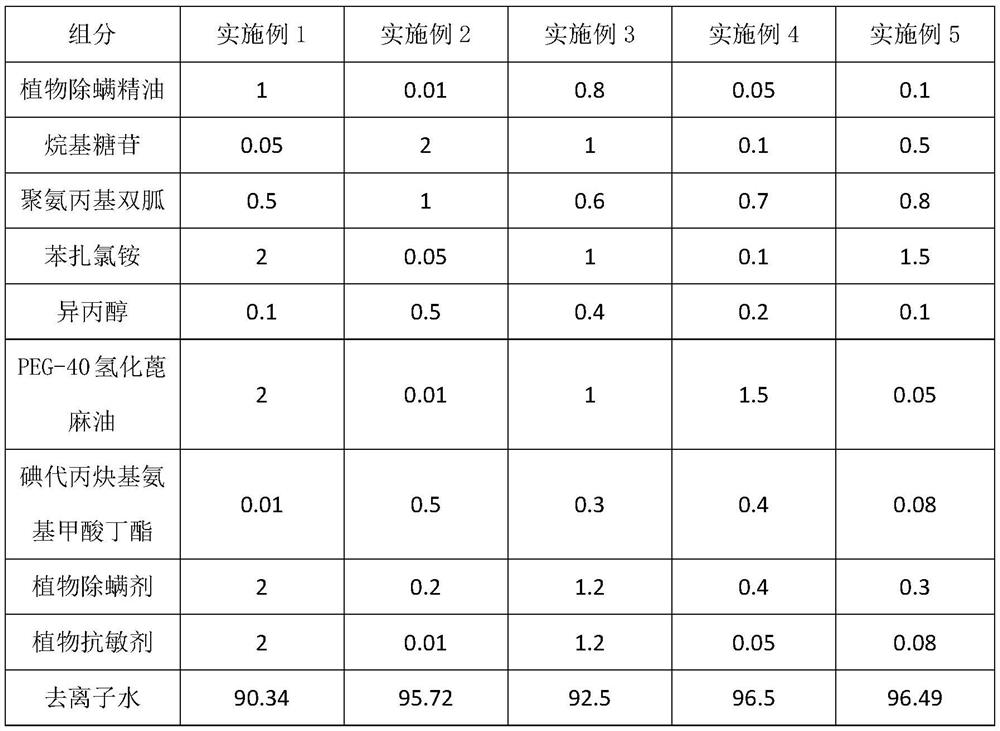

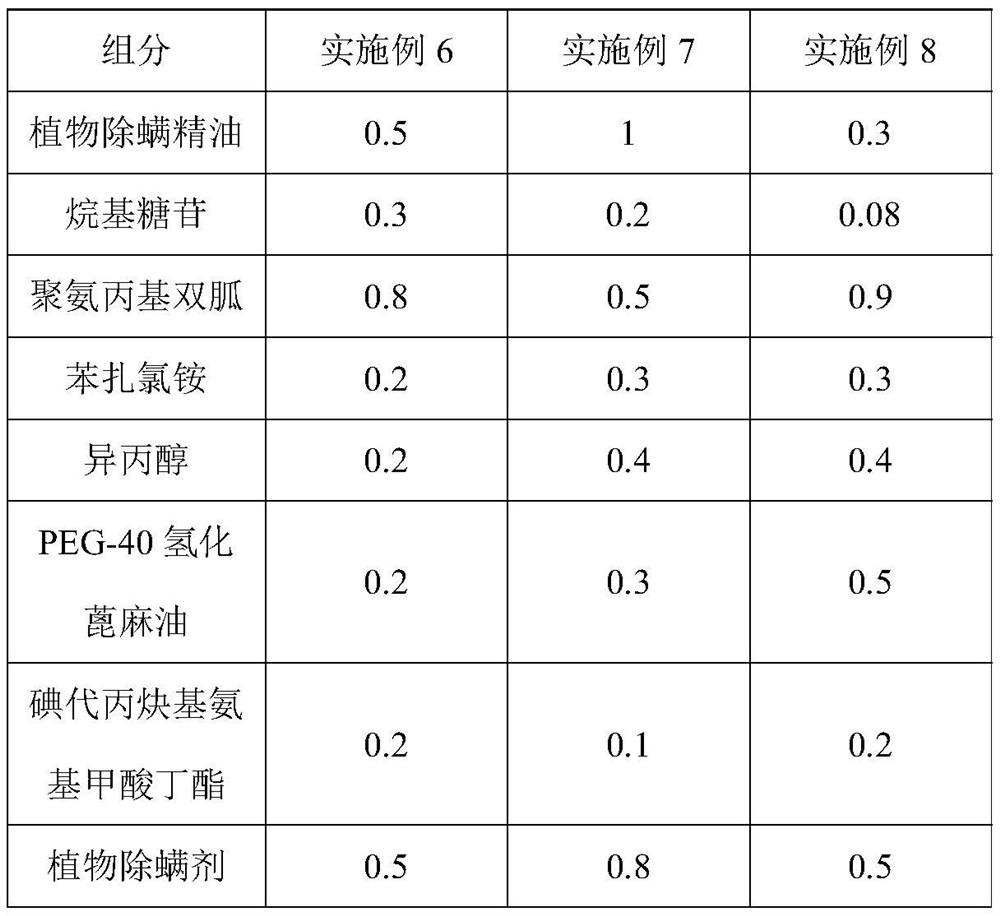

Household sterilizing, cleaning and acarus killing wet tissue

ActiveCN112852556AGood antibacterial and anti-mite effectEasy to cleanOrganic detergent compounding agentsNon-ionic surface-active compoundsGlycosideMicrobiology

The invention discloses a household sterilizing, cleaning and acarus killing wet tissue which comprises a wet tissue body and wet tissue liquid sprayed and dripped on the wet tissue body, and the wet tissue emulsion is sterilizing and acarus killing emulsion and comprises plant acarus killing essential oil, alkyl glycoside, polyaminopropyl biguanide, benzalkonium chloride, isopropanol, PEG-40 hydrogenated castor oil, iodopropynyl butyl carbamate, a plant acarus killing agent, a plant anti-allergy agent and deionized water. The mass ratio of the alkyl glycoside to the polyaminopropyl biguanide to the benzalkonium chloride to the iodopropynyl butyl carbamate is (0.08-0.3): (0.5-0.9): (0.2-0.3): (0.1-0.2). The household sterilizing, cleaning and acarus killing wet tissue is high in cleaning capacity and good in sterilizing and acarus killing effects, meanwhile, the compatibility problem of emulsion and floor plastic is solved, damage to a floor in the cleaning process is avoided, and the household sterilizing, cleaning and acarus killing wet tissue is wide in application.

Owner:MAOMING ZHANGSHI SCI & TECH DEV CO LTD

Architectural thermal insulation coating

InactiveCN105400301AExtended service lifeWidely producedFireproof paintsAntifouling/underwater paintsCelluloseThermal insulation

The invention discloses an architectural thermal insulation coating. Natural latex, nekal, a stabilizer, a dispersant, sulphur, polyvinyl chloride, a promoter, diphenyl guanidine, diethanolamine, 2-aminoethanol, butyl phthalate, hydroxypropyl methyl cellulose, polyvinyl acetate and dithiocarbamate are weighed by weight portion; surface drying time of the product is 10-30 min, and hard drying time is 50-70 min; flame resistant time is 30-50 s, and the product has fire retardance; weight loss is 1-5 g; adhesive force is 100%, and the coating will not fall off or mildew if immersed in water for 20-30d; and gloss is 90-100%, flexibility is 1-3 mm, and service life of a coating film is long.

Owner:CHANGSHU RES INSTITUE OF NANJING UNIV OF SCI & TECH

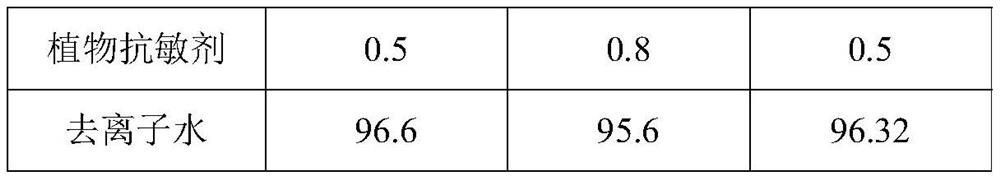

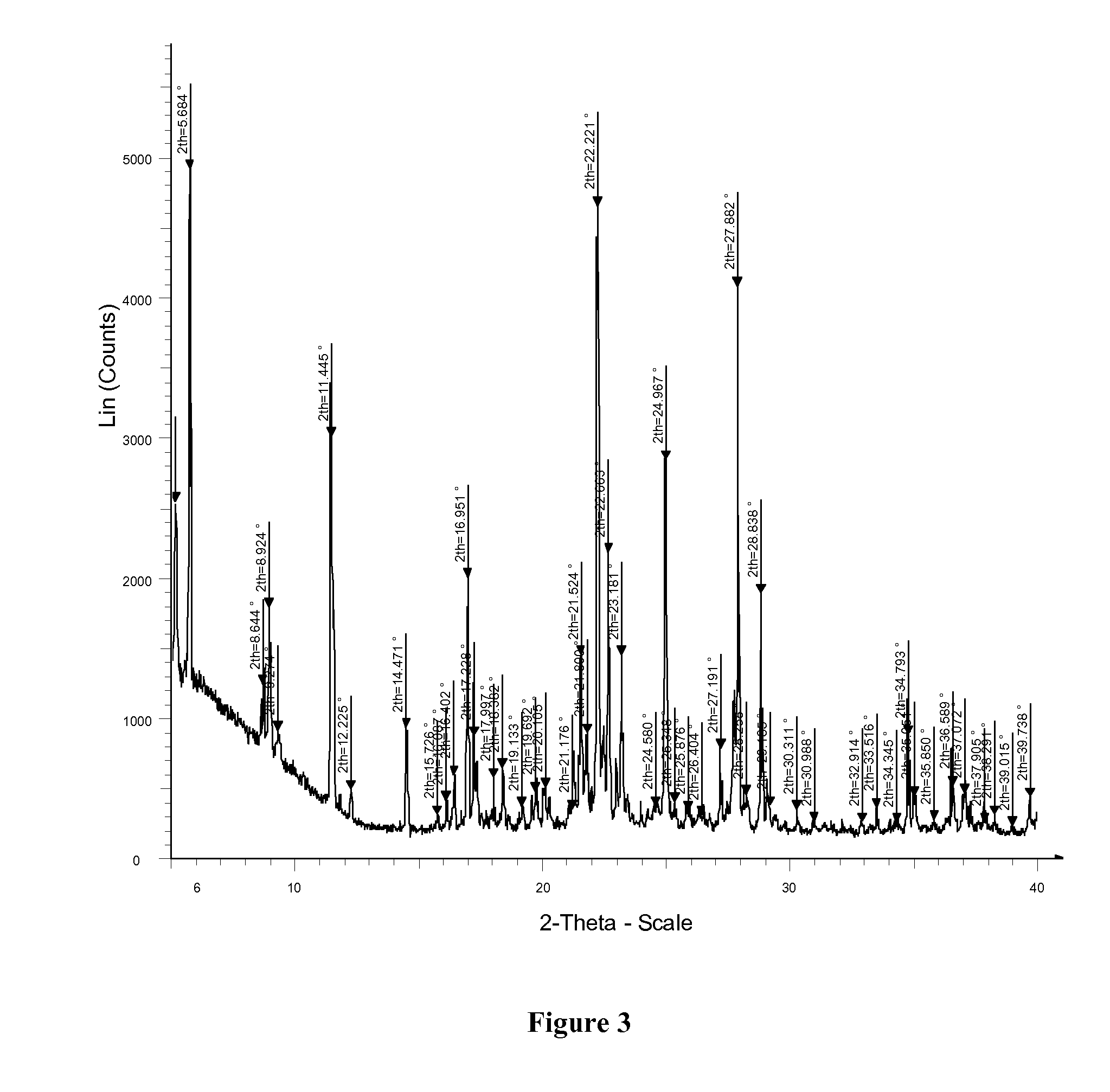

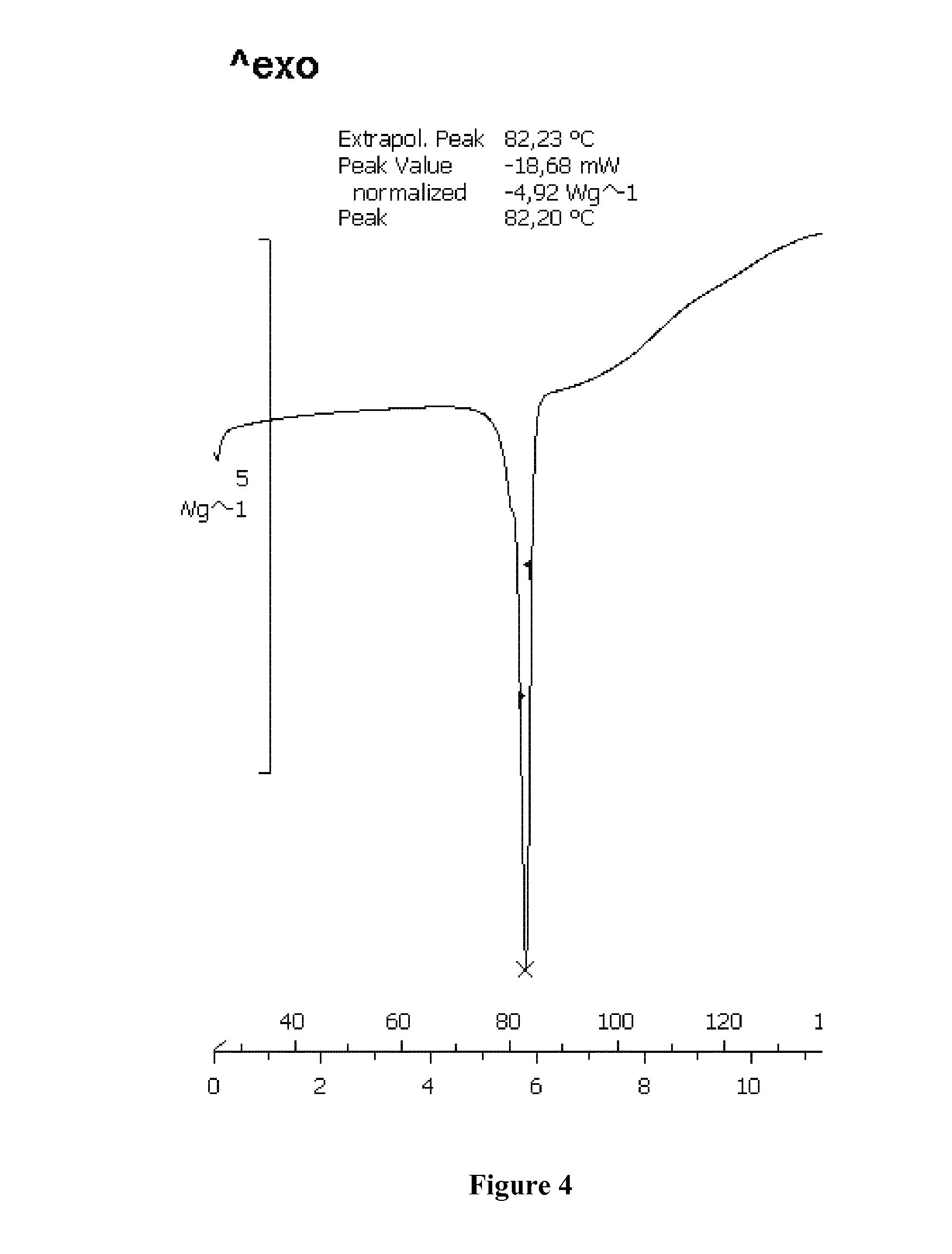

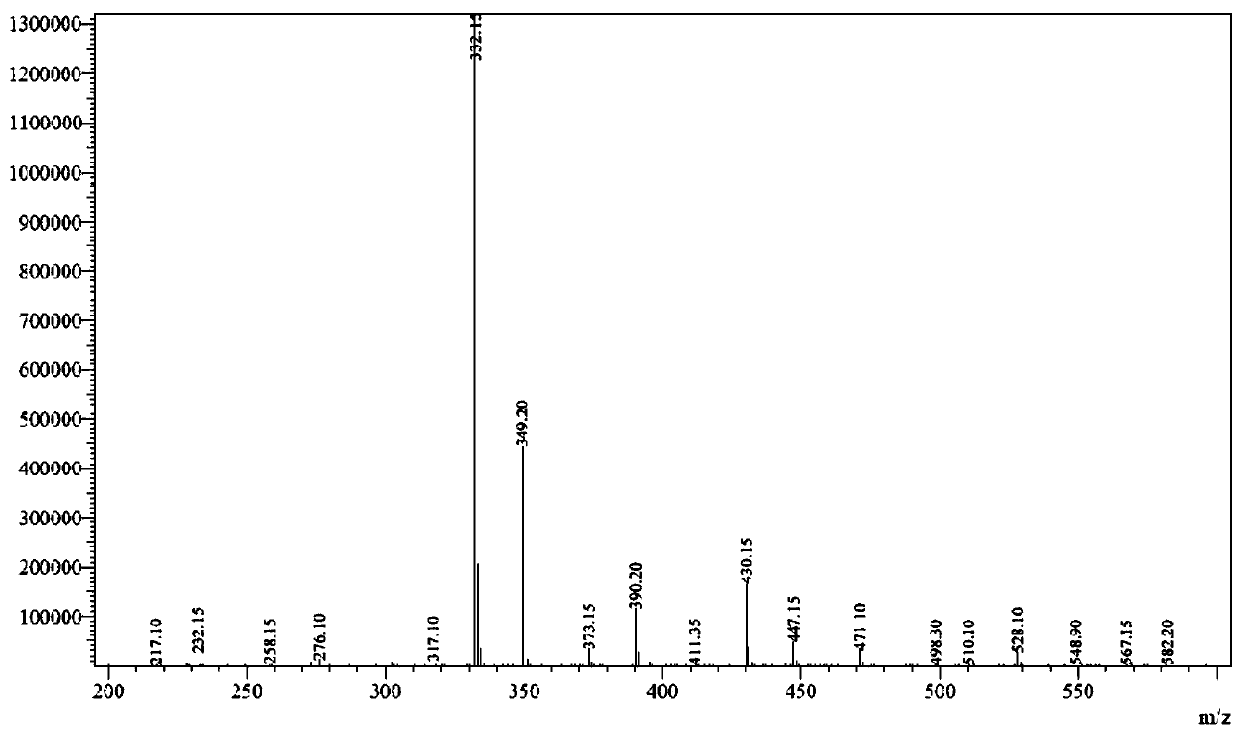

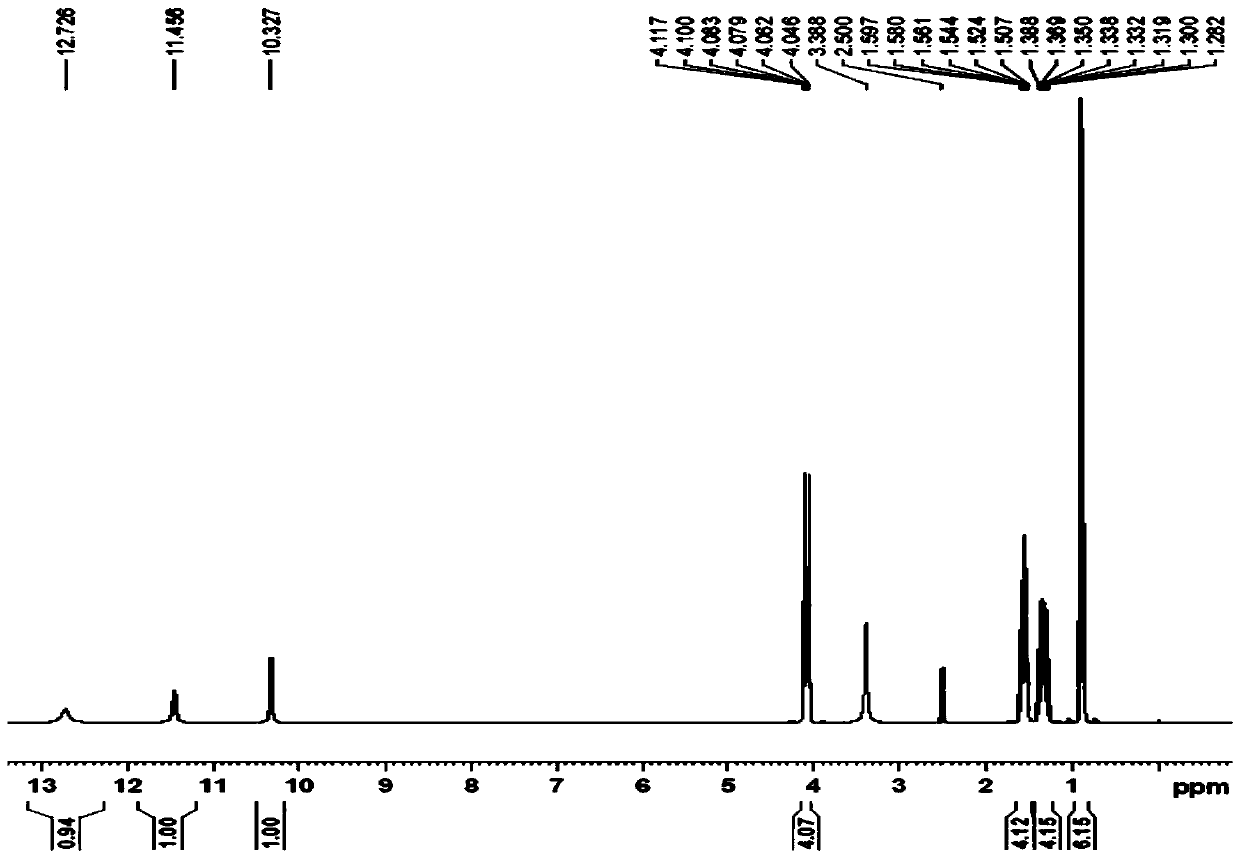

Co-Crystals of 3-Iodopropynyl Butylcarbamate

ActiveUS20150051280A1Advantageous chemico-physical propertyGood water solubilityBiocideDead animal preservationCompound (substance)Biology

The present invention relates to biocidal agents designed to protect industrial products against microbial, bacterial, fungal and algal infections. In particular, the present invention relates to co-crystals containing 3-iodopropynyl butylcarbamate (IPBC) and to compositions containing said co-crystals which possess improved physical, chemical and workability properties compared with the use of IPBC.

Owner:POLITECNICO DI MILANO

Preparation method of diclazuril impurity A

InactiveCN111517991AShort synthetic routeStarting materials are readily availableCarbamic acid derivatives preparationOrganic compound preparationAcyl groupFormic acid ethyl ester

The invention discloses a preparation method of a diclazuril impurity A. The diclazuril impurity A is obtained through the procedures of condensation reaction of a diclazuril intermediate (3-butyloxycarbonylamino-3-oxopropionyl)-butyl carbamate or (3-ethoxycarbonylamino-3-oxopropionyl)-ethyl carbamate (compound I) used as a starting material with sodium nitrite in a polar solvent and under acid catalysis, decoloration, crystallization and drying. The synthesis route is short, the starting material is easy to obtain, reaction conditions are mild, operation is easy and convenient, the impurity can be obtained without column chromatography, the purity of the prepared impurity can reach 99.5% or above, and the impurity can serve as a reference substance to be used for quality research.

Owner:CHANGZHOU YABANG QH PHARMACHEM +2

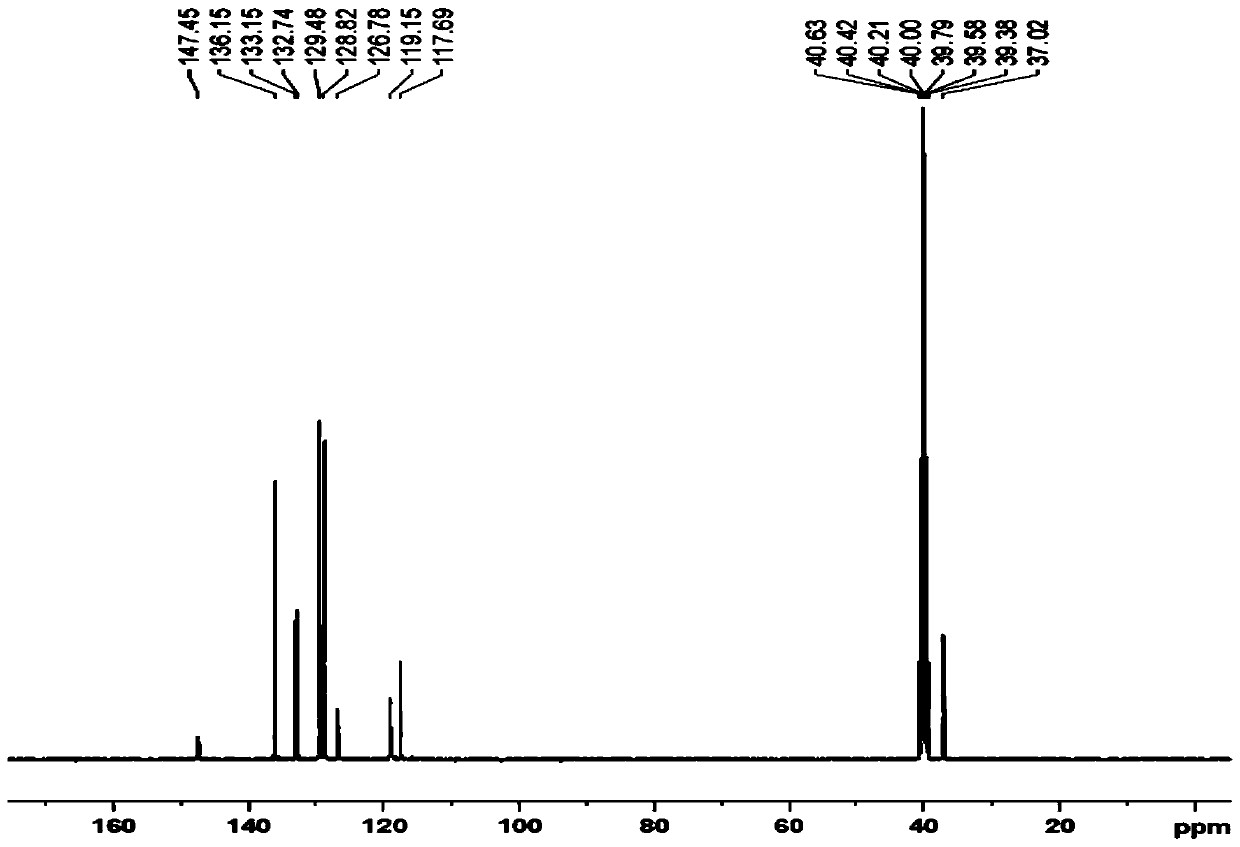

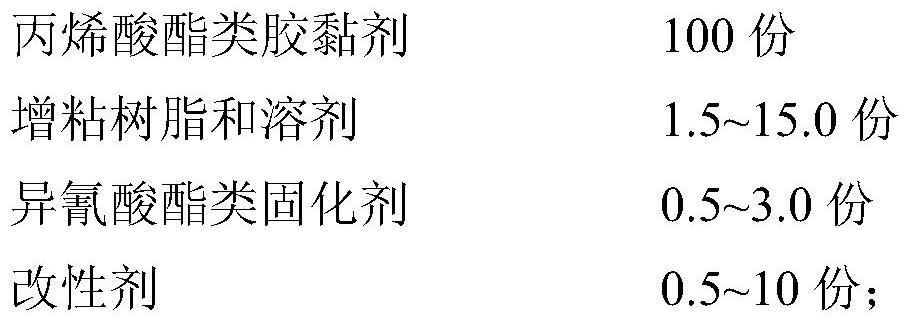

A kind of acrylate adhesive composition and preparation method thereof

ActiveCN109575846BImprove adhesionLow costNon-macromolecular adhesive additivesEster polymer adhesivesPolymer scienceAdhesive

The invention relates to an acrylic adhesive composition and a preparation method thereof. The acrylic adhesive composition consists of the following raw materials and their parts by mass: 100 parts of acrylic adhesive, a tackifying resin and a solvent 1.5-15.0 parts, 0.5-3.0 parts of isocyanate curing agent, 0.5-10 parts of modifier; wherein, the modifier is at least one of dioctyl adipate and butyl phthalate. Compared with the prior art, the present invention has the advantages that: the acrylic adhesive composition of the present invention has good initial adhesion and long-lasting adhesion, and still maintains high performance when the temperature range is large; the adhesive The adhesive tape made of the adhesive composition can meet the technical requirements of the express delivery industry for packaging cartons in terms of bonding strength (carton tearing rate), stickiness, initial tack and weather resistance to corrugated boxes, and the cost of the adhesive tape is low.

Owner:NINGBO SOKEN CHEM

Fabric thermal insulation coating and preparation method thereof

InactiveCN105401447AExtended service lifeImprove adhesionHeat resistant fibresCellulosePolymer science

The invention discloses a fabric thermal insulation coating and its preparation method. According to the invention, natural latex, nekal, a stabilizer, a dispersant, a vulcanizing agent, polyvinyl chloride, a promoter, diphenyl guanidine, diethanolamine, 2-aminoethanol, butyl phthalate, hydroxypropyl methyl cellulose, polyvinyl acetate and dithiocarbamate are weighed by weight portion. Technical effects are as follows: surface drying time of the product is 10-25min and hard drying time is 50-65 min; flame resistant time is 35-50 s, and the product has flame resistance; weight loss is 1-4 g; adhesive force reaches up to 100%, and the product will not fall off or mildew after immersed in water for 22-30 d; gloss reaches 93-100%, and flexibility is 1.5-3 mm; and service life of a coating film is long. The product can be widely produced and can continuously replace existing materials.

Owner:CHANGSHU RES INSTITUE OF NANJING UNIV OF SCI & TECH

Drying and anti-mildew bactericide for garments

InactiveCN105076183AThe preparation process is simpleEasy to manufactureBiocideFungicidesBiotechnologyBenzoic acid

The invention relates to a drying and anti-mildew bactericide for garments. The drying and anti-mildew bactericide comprises components in parts by mass as follows: 28-32 parts of iminoctadine tris(albesilate), 30-34 parts of silthiopham, 26-30 parts of amino-oligosaccharin, 30-34 parts of quintozene, 26-30 parts of oxadixyl, 30-34 parts of vancomycin, 26-30 parts of sodium diacetate, 32-36 parts of tetrabutyl titanate, 26-30 parts of ammonium perchlorate, 30-34 parts of ethyl p-hydroxybenzoate, 26-30 parts of polyoxyethylene trimethyl ammonium chloride, 30-34 parts of dimethyl fumarate, 26-30 parts of 3-iodine-2-propynyl butyl carbamate, 30-34 parts of benzimidazole, 26-30 parts of iodo propynyl butyl carbamate, 30-34 parts of bauxite, 26-30 parts of potato modified starch, 30-34 parts of bamboo charcoal, 26-30 parts of light calcined magnesia and 30-34 parts of polyacrylamide starch. The drying and anti-mildew bactericide for the garments has excellent drying, anti-mildew and anti-bacterial performance and is fit for use in the field of garments.

Owner:王璐

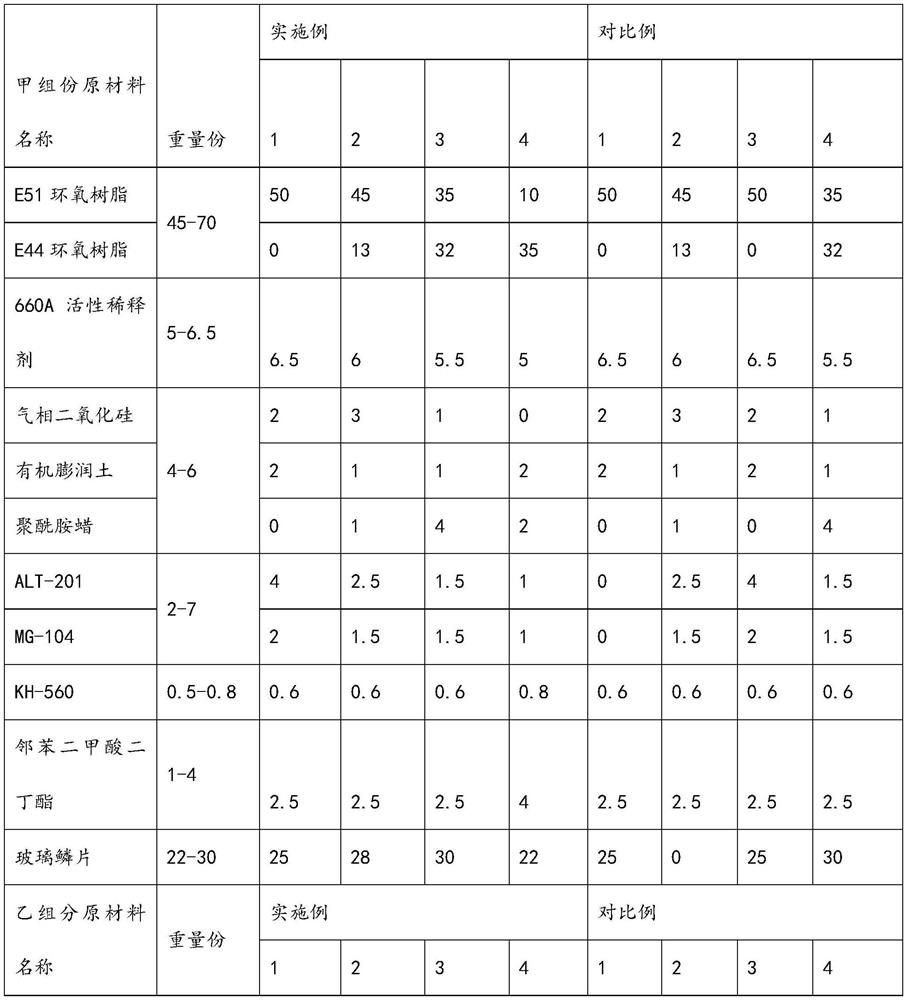

A kind of underwater curable epoxy glass flake paint and preparation method thereof

ActiveCN113416466BImprove anti-corrosion performanceGood flexibilityAnti-corrosive paintsEpoxy resin coatingsPolymer sciencePolyamide

The invention relates to the technical field of coatings, and provides an epoxy glass flake coating that can be cured underwater and a preparation method thereof, wherein the coating includes component A and component B, and component A includes bisphenol A epoxy resin and a reactive diluent , thixotropic agent, water remover, coupling agent, butyl phthalate and glass flakes; component B includes curing agent, pigment and filler, thixotropic agent and liquid petroleum resin; curing agent is made of modified polyamide and modified The active hydrogen equivalent of the modified polyamide is 80-200, and the viscosity at 40°C is 3000-21000mPa.s; the active hydrogen equivalent of the modified phenalkamine is 70-120. The resin system provided by the present invention selects the bisphenol A epoxy resin system with good anticorrosion performance, and the curing agent has good flexibility and can be cured on a wet surface. Modified polyamide and modified phenolic resin with good anticorrosion performance and block reaction rate A combination of amines that improves wet surface cure and aids in the curing of coatings in underwater environments.

Owner:XIAMEN SUNRUI SHIP COATING

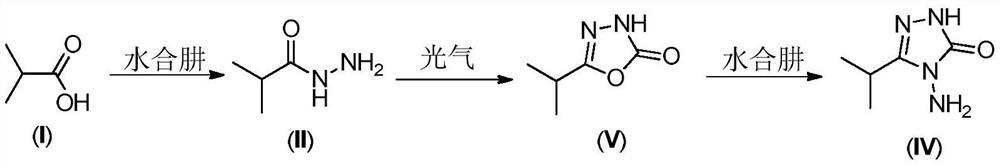

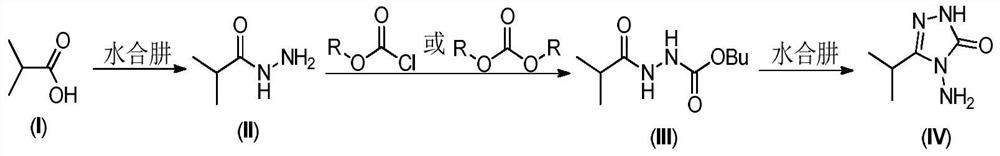

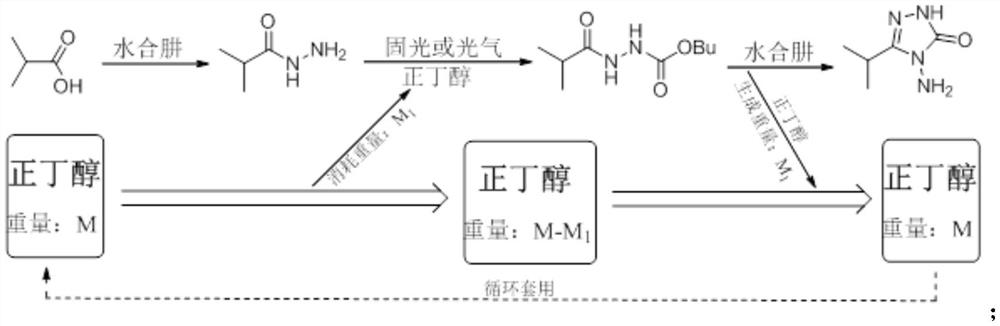

A method for preparing 3-isopropyl-4-amino-1,2,4-triazolin-5-one

Owner:北京怡力生物科技有限公司

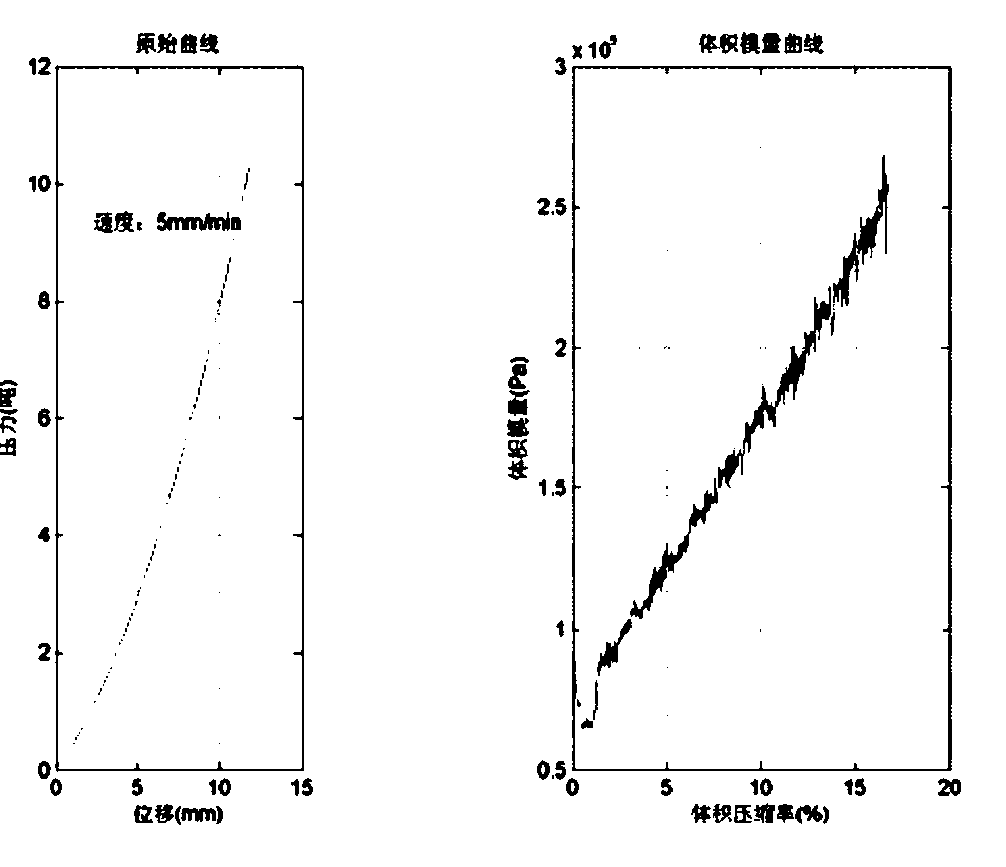

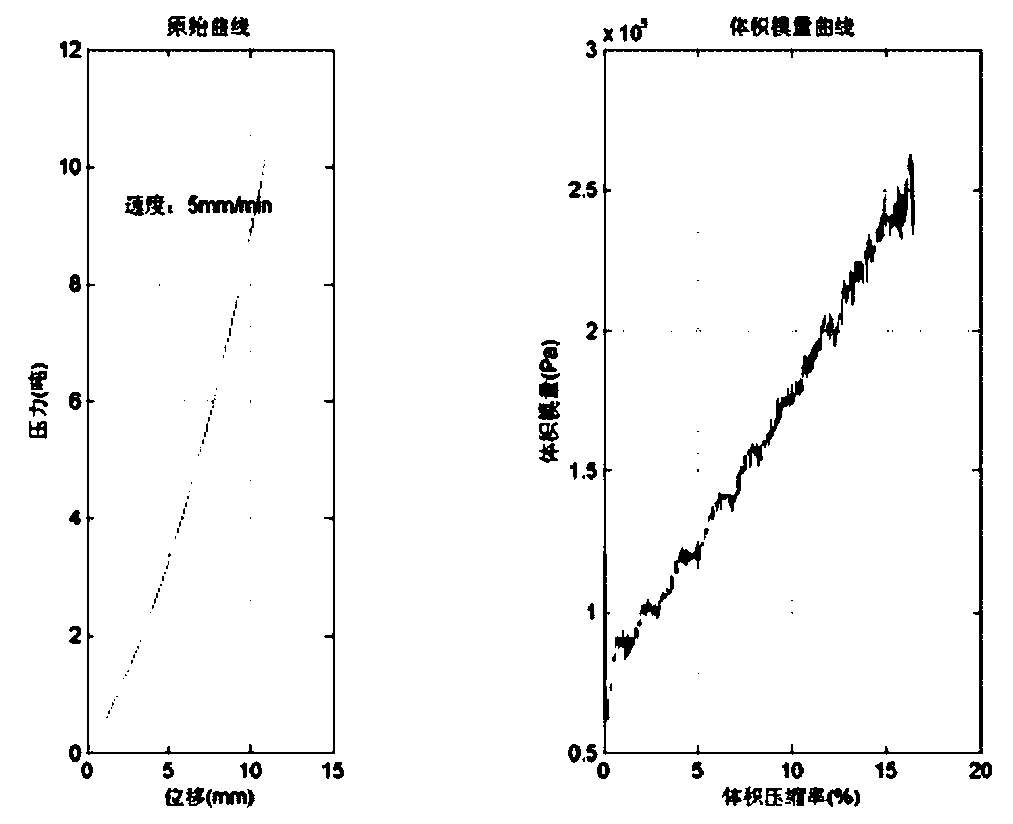

Temperature-insensitive high-damping elastic gumming dirt buffering material and preparation method thereof

The invention discloses a temperature-insensitive high-damping elastic gumming dirt buffering material and a preparation method thereof, which relate to an elastic gumming dirt damping buffer material. The temperature-insensitive high-damping elastic gumming dirt buffering material comprises the following components in parts by weight: 100 parts of silicon rubber, 1-10 parts of methyl silicone oil serving as a viscosity modifier, 0.1-2 parts of a compression resisting agent, 0.5-10 parts of a filler, 0.5-5 parts of carbon black serving as a reinforcing agent, 0.1-1 part of dioctyl adipate (DOA) serving as a cold-resistant plasticizer, 0.5-5 parts of hydrogen-containing silicon oil serving as a softening agent and 1-10 parts of a side-chain polysiloxane liquid crystal elastomer, wherein the liquid crystal elastomer contains 4-(omega-acrylate ethyoxyl ester group)benzoyloxy-4'-benzoic acid smectic liquid crystal element (M) and a di-4-(para-allyloxy)benzoyloxy-4'-butyl benzoate (N) smectic liquid crystal crosslinking agent. Due to the adoption of the temperature-insensitive high-damping elastic gumming dirt buffering material, the elasticity, order and liquidity of gumming dirt are improved, and the use requirements of a high-absorbing-power gumming dirt buffer are met.

Owner:ZHONGBEI UNIV

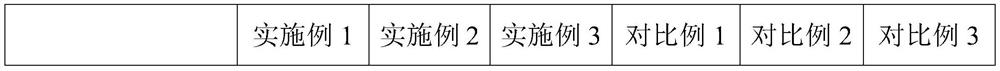

High-strength waterproof anti-cracking putty powder and preparation method thereof

ActiveCN114015272AImprove mechanical propertiesEvenly dispersedFilling pastesPolymer scienceCarbon nanotube

The invention relates to the field of high polymer materials, in particular to high-strength waterproof anti-cracking putty powder and a preparation method thereof, and the high-strength waterproof anti-cracking putty powder comprises a first component, a second component and a third component; the first component is prepared from the following components: unsaturated polyester resin, cobalt naphthenate, hydroxylated multi-walled carbon nanotubes, hydroxypropyl methyl cellulose ether, filler and a thixotropic lubricant; the second component is a curing agent, and the third component is butyl formate. The coating film formed by the putty has good flexibility and impact resistance and good water resistance, and the phenomena of blistering, falling off and stickiness are avoided after the putty is soaked in water at 40 DEG C for 720 h.

Owner:湖南志洲新型干混建材有限公司

Household sterilization cleaning mite removal wipes

ActiveCN112852556BGood antibacterial and anti-mite effectEasy to cleanNon-ionic surface-active compoundsOrganic detergent compounding agentsWet wipeButyl carbamate

The invention discloses a household sterilizing, cleaning and mite-removing wet wipe, which comprises a wet wipe body and a wet wipe liquid sprayed on the wet wipe body, the wet wipe emulsion is the above-mentioned sterilizing and mite-removing emulsion, and the emulsion, Including plant acaricide essential oil, alkyl glucoside, polyaminopropyl biguanide, benzalkonium chloride, isopropanol, PEG‑40 hydrogenated castor oil, iodopropynyl butyl carbamate, plant acaricide, plant allergy agent and deionized water; the mass ratio of the alkyl glucoside, polyaminopropyl biguanide, benzalkonium chloride and iodopropynyl butyl carbamate is 0.08‑0.3:0.5‑0.9:0.2‑0.3:0.1‑ 0.2. The household sterilizing, cleaning and mite-removing wet wipe of the present invention has strong cleaning power and good sterilizing and mite-removing effect, and at the same time, solves the compatibility problem between emulsion and floor plastic, avoids damage to the floor during the cleaning process, and has wide applications.

Owner:MAOMING ZHANGSHI SCI & TECH DEV CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com

![Synthetic method for tert-butyl 1,10-dioxo-2,7-diazaspiro[4.5]decane-7-carboxylate Synthetic method for tert-butyl 1,10-dioxo-2,7-diazaspiro[4.5]decane-7-carboxylate](https://images-eureka.patsnap.com/patent_img/123aef50-11a3-4b9c-87b3-d13af7b7691d/DEST_PATH_IMAGE004.png)

![Synthetic method for tert-butyl 1,10-dioxo-2,7-diazaspiro[4.5]decane-7-carboxylate Synthetic method for tert-butyl 1,10-dioxo-2,7-diazaspiro[4.5]decane-7-carboxylate](https://images-eureka.patsnap.com/patent_img/123aef50-11a3-4b9c-87b3-d13af7b7691d/100002_DEST_PATH_IMAGE002.png)

![Preparation method of 3-oxymethylene-7-oxa-2,10-diazaspiro[4,6] undecane-10-tert-butyl formate Preparation method of 3-oxymethylene-7-oxa-2,10-diazaspiro[4,6] undecane-10-tert-butyl formate](https://images-eureka.patsnap.com/patent_img/88c175dd-a565-4a4e-b464-9f0e53bb5365/DEST_PATH_IMAGE001.png)