Water-borne composite organic wood preservative, preparation method and application thereof

A wood preservative, water-borne technology, applied in the field of wood preservatives, can solve the problems of high production costs, environmental pollution, etc., achieve the effects of low usage, avoiding large-scale use, and reducing toxicity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

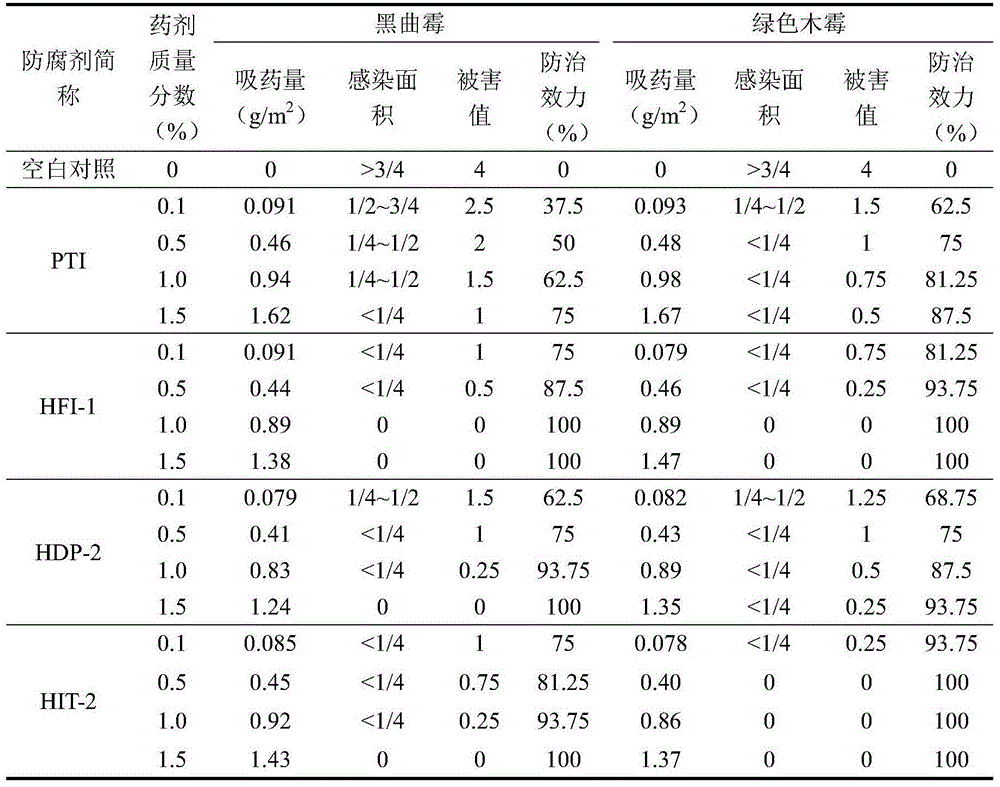

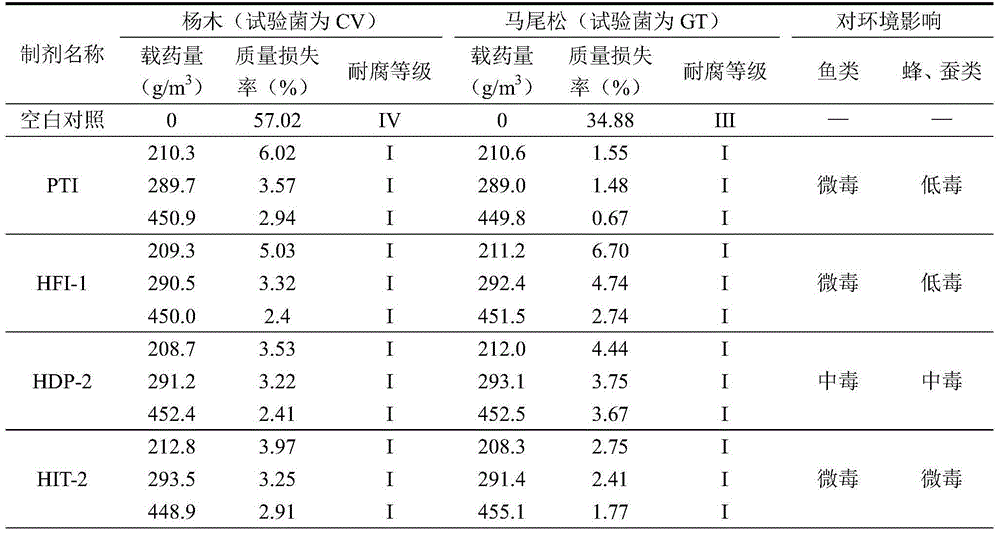

[0023] The water-borne composite organic wood preservative of this embodiment includes the following components in mass percentage: propiconazole 7.18%, tebuconazole 7.22%, imidacloprid 0.72%, cyclohexanone 15%, dimethylformamide 8%, xylene 6%, tristyrylphenol polyoxyethylene ether 11.2%, calcium dodecylbenzenesulfonate 3.8%, and the rest is water.

[0024] The preparation method of embodiment 1: dissolve 37g 97% propiconazole, 38g 95% tebuconazole and 3.7g 97% imidacloprid in 75g cyclohexanone, 40g dimethylformamide and 30g xylene, stir until completely dissolved , add 56g tristyrylphenol polyoxyethylene ether and 19g calcium dodecylbenzenesulfonate, mix uniformly, add 201g water under stirring, continue to stir until material is homogeneous transparent liquid, promptly gets 15.12% (with propane The sum of cycloconazole, tebuconazole and imidacloprid) organic wood preservative (referred to as PTI).

Embodiment 2

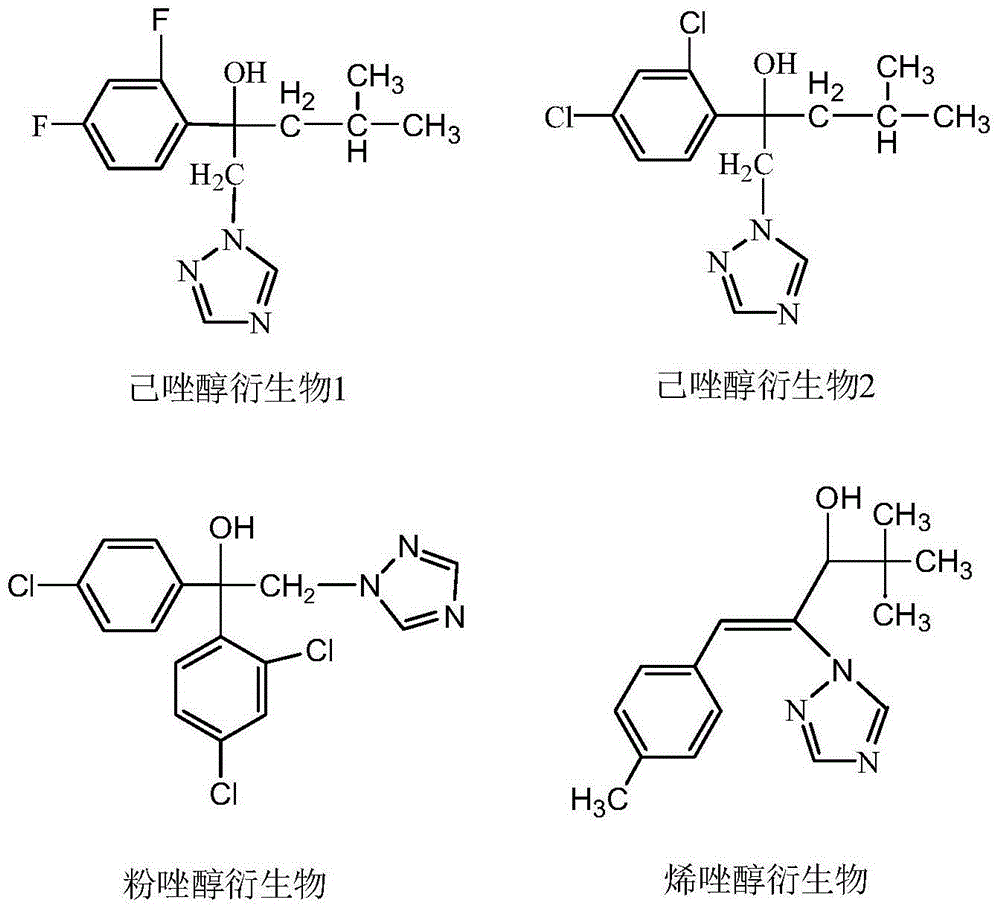

[0026] The water-borne composite organic wood preservative of the present embodiment comprises the following components in mass percentage: 14.75% of hexaconazole derivatives, 4.86% of fuconazole derivatives, 0.48% of imidacloprid, 25% of cyclohexanone, 10% of methyl formamide, 5% of xylene, 16% of tristyrylphenol polyoxyethylene ether and 4% of calcium dodecylbenzenesulfonate, and the rest is water.

[0027] The preparation method of embodiment 2: 25g 95% hexaconazole derivative 1, 27g 90% fuconazole derivative and 2.4g 97% imidacloprid are dissolved in 125g cyclohexanone, 50g dimethylformamide and 25g xylene , stir until completely dissolved, add 80g tristyrylphenol polyoxyethylene ether and 20g calcium dodecylbenzenesulfonate, mix evenly, add 156g water under stirring, continue stirring until the material is a homogeneous transparent liquid, to obtain 10.09% (based on the sum of hexaconazole derivative 1, triconazole derivative and imidacloprid) organic wood preservative (H...

Embodiment 3

[0029] The waterborne composite organic wood preservative of this embodiment includes the following components in mass percentage: 22.52% of hexaconazole derivatives, 2.52% of diniconazole derivatives, 0.24% of permethrin, and 15% of cyclohexanone , 10% of dimethylformamide, 5% of xylene, 7.5% of nonylphenol polyoxyethylene ether, 7.5% of castor oil polyoxyethylene ether and 5% of calcium dodecylbenzenesulfonate, and the rest is water.

[0030] The preparation method of embodiment 3: 14g 90% hexaconazole derivative 2, 14g 90% diniconazole derivative and 1.2g 97% permethrin are dissolved in 75g cyclohexanone, 50g dimethylformamide and 25g dimethicone In toluene, stir until completely dissolved, add 37.5g nonylphenol polyoxyethylene ether, 37.5g castor oil polyoxyethylene ether and 25g calcium dodecylbenzenesulfonate, mix well, add 221g water under stirring, continue stirring Until the material is a homogeneous transparent liquid, 6.24% (based on the sum of hexaconazole derivati...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com