A kind of permeable concrete and preparation method thereof

A permeable concrete and mixture technology, applied in the field of concrete, can solve problems such as easy to block the lower pores, affect the permeable performance, hinder the permeable pores, etc., achieve the effects of reducing clogging, enhancing the permeable effect, and reducing the retention time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

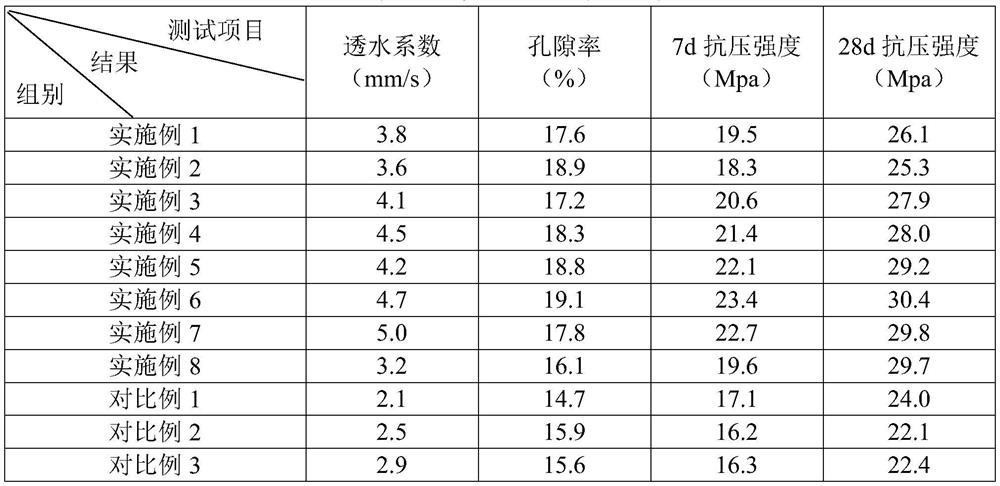

Examples

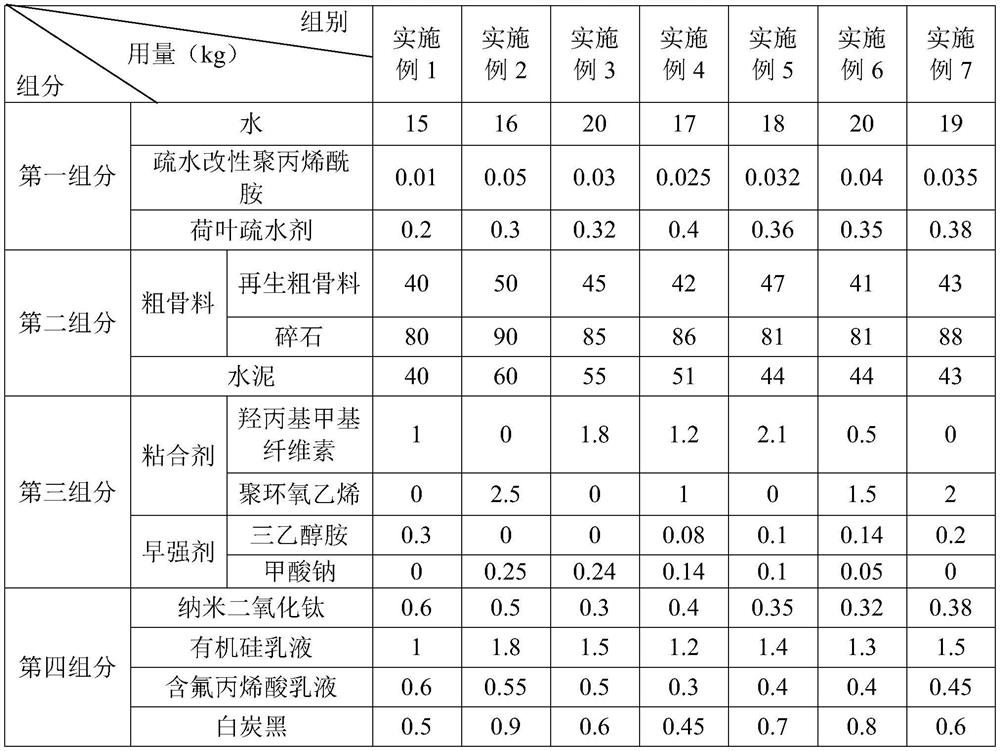

Embodiment 1

[0032] First disperse 0.5kg of white carbon black and 0.6kg of nano-titanium dioxide in 5 parts of water to obtain the first suspension, then dissolve 0.01kg of hydrophobically modified polyacrylamide in 10 parts of water to obtain a hydrophobically modified polyacrylamide solution. The above-mentioned first suspension and the above-mentioned hydrophobically modified polyacrylamide solution were uniformly mixed to obtain a second suspension, and then 0.2 kg of lotus leaf hydrophobic agent, 1 kg of silicone emulsion and 0.6 kg of fluorine-containing acrylic acid emulsion were added to the above-mentioned second suspension, Mix well to obtain the first mixture.

[0033] Take 40kg of recycled coarse aggregate, 80kg of gravel, 40kg of cement, 1kg of hydroxypropyl methylcellulose and 0.3kg of triethanolamine and mix them uniformly to obtain the second mixture. Among them, the particle size of recycled coarse aggregate and crushed stone is 7 (± 1) mm.

[0034] The above-mentioned f...

Embodiment 2

[0036] Except that binding agent selects polyethylene oxide for use, and early strength agent selects sodium formate for use, and the consumption of each component is different from Example 1, and all the other operations are all the same as Example 1. The components and their amounts are shown in Table 1.

Embodiment 3

[0038] Except that sodium formate is selected as the early strength agent, and the dosage of each component is different from that of Example 1, the rest of the operations are the same as in Example 1. The components and their amounts are shown in Table 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com