Temperature thermal insulation baffle for directional crystallization furnace

A heat-insulating baffle and directional crystallization technology, which is applied in crystal growth, single crystal growth, chemical instruments and methods, etc., can solve the problem of high pass rate of single crystal blade preparation, improve the preparation quality and pass rate, and use quickly and conveniently , cost-saving effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

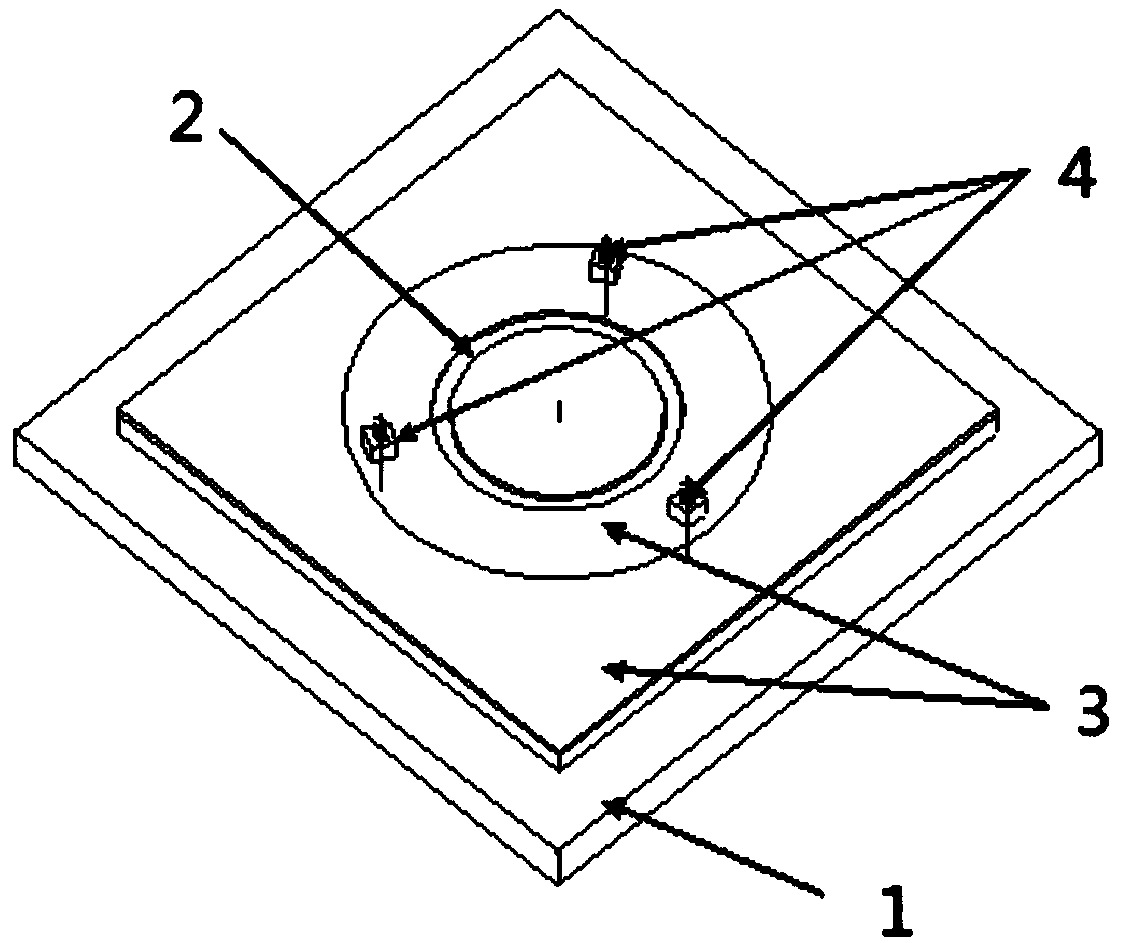

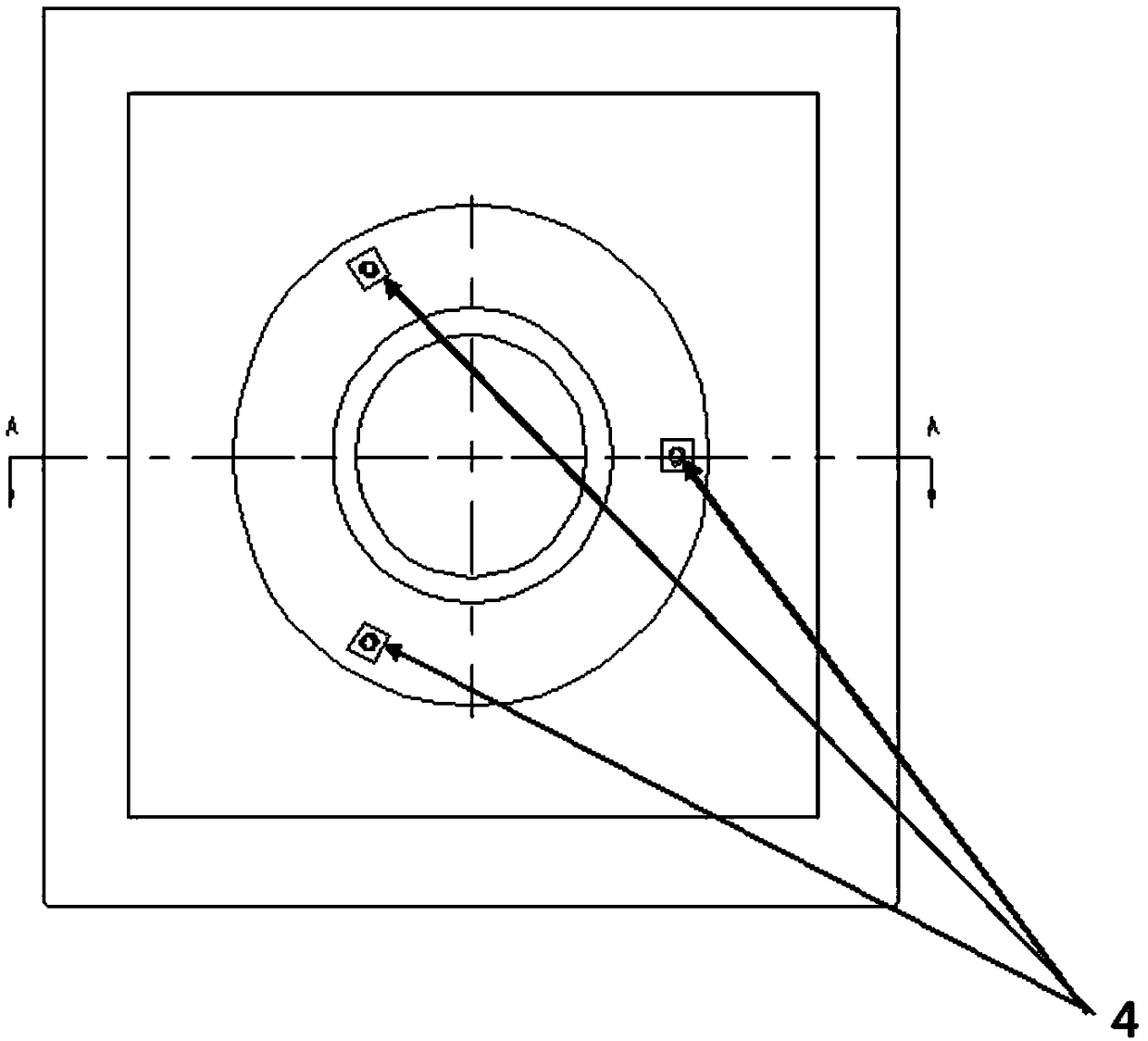

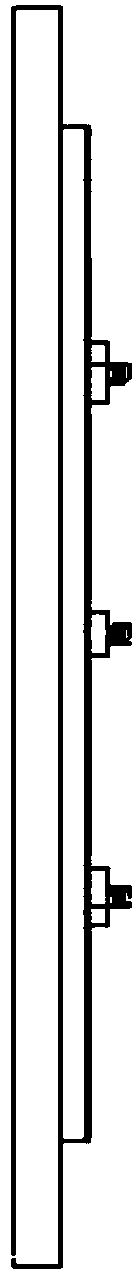

[0029] Described directional crystallization furnace temperature constitutes as follows with heat insulation baffle: hard graphite carbon felt layer 1, soft graphite carbon felt layer 2, graphite paper layer 3 and connector 4; On the graphite carbon felt layer 1, the graphite paper layer 3 is located on the soft graphite carbon felt layer 2. The heat insulation baffle for the temperature of the directional crystallization furnace is optimized for the heat insulation baffle of the resistance heating directional crystallization furnace.

[0030] The thickness of the hard graphite carbon felt layer 1 is 15-25 mm, the thickness of the soft graphite carbon felt layer 2 is 5-15 mm, and the thickness of the graphite paper layer 3 is 2-4 mm.

[0031] The aperture of described hard graphite carbon felt layer 1 is that the aperture of hard graphite carbon felt layer 1 is Φ (A+20) mm, and the aperture of soft graphite carbon felt layer 2 is Φ (A-20) mm, wherein, crystallizer size is ΦAm...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com