Device and method for detecting defects of large-diameter plane mirror based on line scanning and ring belt splicing

A defect detection and line scanning technology, applied in the field of optical detection, can solve the problems of large sub-aperture data imaging distortion, distortion correction position correction, large amount of intermediate data, etc., to achieve simple and accurate position error correction, small calculation amount, and large amount of data small effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0039] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

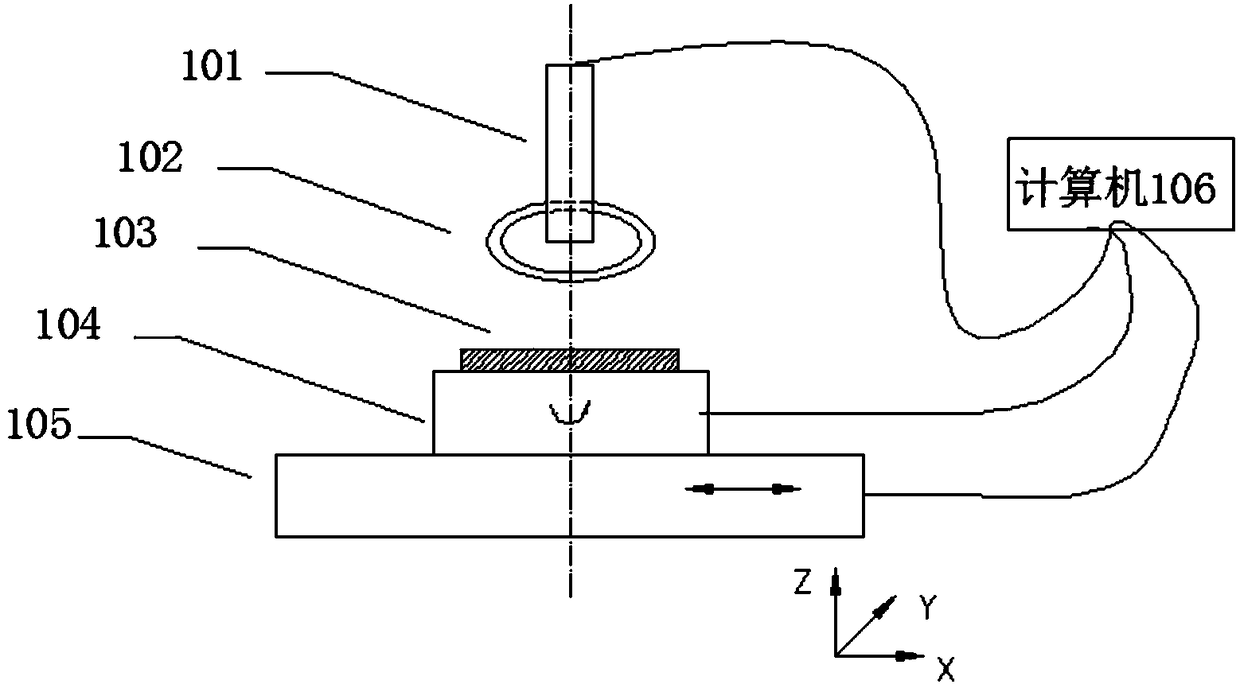

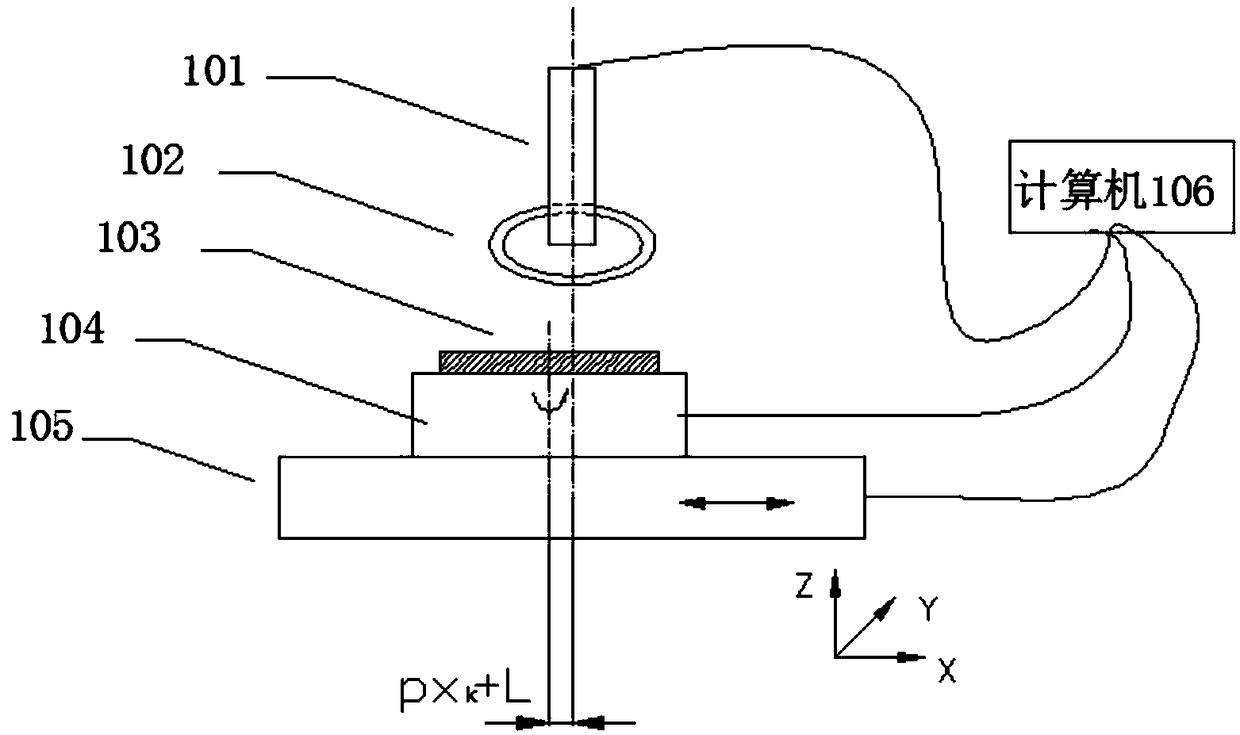

[0040] figure 1 It is a schematic diagram of a defect detection device for a large-diameter plane mirror based on line scanning and ring splicing of the present invention, including a line scanning detector 101, an annular illumination source 102, a plane mirror under test 103, a rotating table 104 around the Z axis, and The translation platform 105 of X axis, computer 106, the structural representation of its device is as figure 1 shown. The XYZ coordinate system is the coordinate system of the rotating stage 104 around the Z axis and the translation stage 105 along the X axis. Wherein, the rotating platform 104 around the Z axis realizes the rotation around the Z direction, and the translation platform 105 along the X axis realizes the translation along the X direction. The rotating platform 104 around the Z axis is placed on the translati...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com