Lithium supplement device for pole piece and lithium supplement method

A pole piece and lithium replenishment technology, applied in battery electrodes, electrical components, circuits, etc., to achieve the effect of improving the consistency of lithium replenishment, improving production efficiency and efficiency, and reducing equipment costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

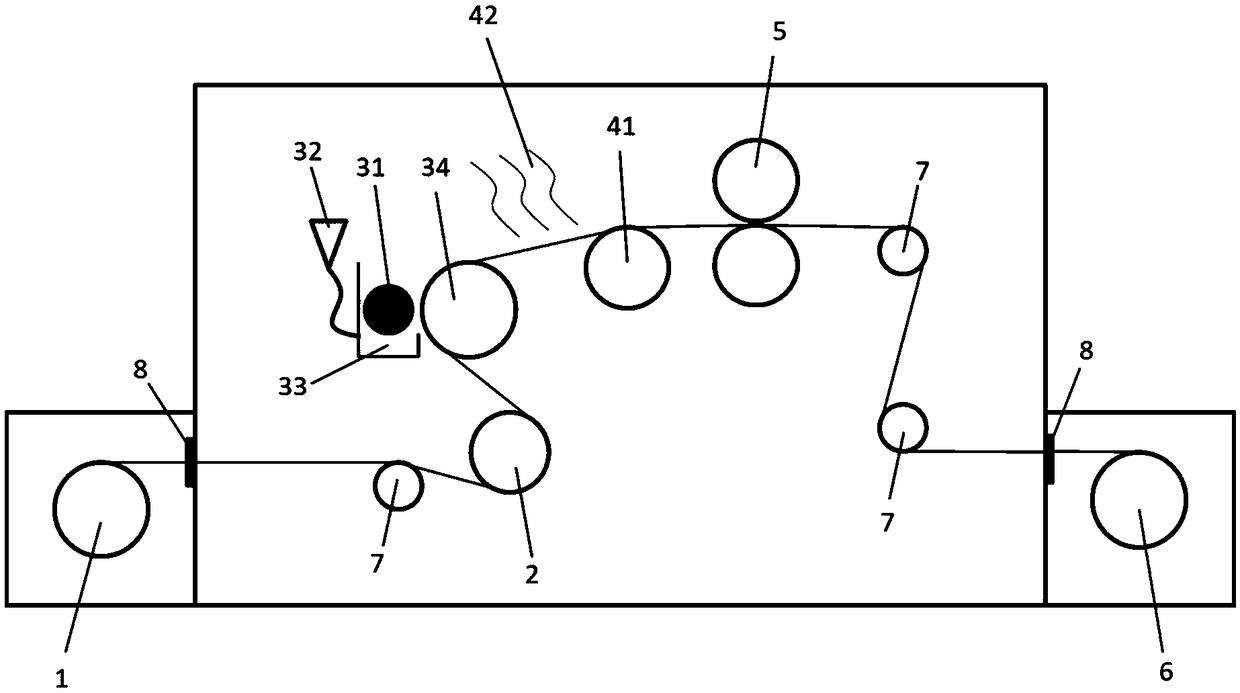

[0049] This embodiment provides a use figure 1 The method for supplementing lithium of the negative electrode pole piece with the shown pole piece lithium supplementing device, the method is:

[0050] The lithium liquid production device will prepare lithium solids into lithium liquid under the heating condition of 100°C, and the lithium liquid will be transported to the lithium liquid storage tank through pipelines, and the pipeline, lithium liquid storage tank and gravure roller will be cleaned before coating the lithium liquid. Keep warm to 100°C, when the lithium liquid is brought into the groove of the gravure roll, cool the gravure roll to 50°C with a dew point of -20°C and a dew point of -5°C, and the negative pole piece passes through The pole piece unwinding assembly is sent to the lithium liquid coating assembly. When the negative pole piece passes through the counter roll composed of a gravure roll and a hot back roll, the gravure roll coats the lithium liquid onto ...

Embodiment 2

[0052] This embodiment provides a use figure 1 The method for supplementing lithium of the negative electrode pole piece with the shown pole piece lithium supplementing device, the method is:

[0053] The lithium liquid production device will prepare lithium solids into lithium liquid under the heating condition of 400°C, and the lithium liquid will be transported to the lithium liquid storage tank through pipelines, and the pipeline, lithium liquid storage tank and gravure roll will be cleaned before coating the lithium liquid. Carry out heat preservation to 400°C, when the lithium liquid is brought into the groove of the gravure roll, cool the gravure roll to 280°C with a dew point of 60°C and a dew point of -65°C. The sheet unwinding assembly is sent to the lithium liquid coating assembly. When the negative pole piece passes through the counter roll composed of a gravure roll and a hot back roll, the gravure roll coats the lithium liquid on the surface of the pole piece, an...

Embodiment 3

[0055] This embodiment provides a use figure 1 The method for supplementing lithium of the negative electrode pole piece with the shown pole piece lithium supplementing device, the method is:

[0056] The lithium liquid production device will prepare lithium solids into lithium liquid under the heating condition of 100°C, and the lithium liquid will be transported to the lithium liquid storage tank through pipelines, and the pipeline, lithium liquid storage tank and gravure roller will be cleaned before coating the lithium liquid. Keep warm to 100°C, when the lithium liquid is brought into the groove of the gravure roll, cool the gravure roll to 80°C with a cold dry gas with a dew point of 0°C, and the negative pole piece passes through the pole piece The unwinding assembly is sent to the lithium liquid coating assembly. When the negative pole piece passes through the counter roll composed of a gravure roll and a hot back roll, the gravure roll coats the lithium liquid on the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com