Asphalt dip-coating process and system

An asphalt and dip-coating technology, which is applied in the process and system field of dip-coating asphalt, can solve the problems of sticking rolls, unqualified finished products, difficulty in coating and achieving the expected effect, etc., and achieve the effect of avoiding air bubbles and solving sticking rolls

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0055] A process for dipping bitumen, which is used for dipping bitumen on a base cloth to make a waterproof membrane with tires, comprising the following steps:

[0056] S1. Pre-impregnation: apply asphalt to the surface of the base fabric or dip the base fabric into asphalt so that the asphalt covers the surface of the base fabric, and then apply the asphalt-coated base in a direction at an acute angle to the vertical direction cloth for extrusion;

[0057] S2. Drying: drying the prepreg tire base treated in step S1 by contacting the rolling heating element;

[0058] S3. Coating: apply asphalt on the surface of the prepreg base treated in step S2 or dip the prepreg base into asphalt so that the asphalt covers the surface of the prepreg base, and then use a high-speed rolling heating element for rough pressing and reuse Roll the heating element at low speed for fine pressing.

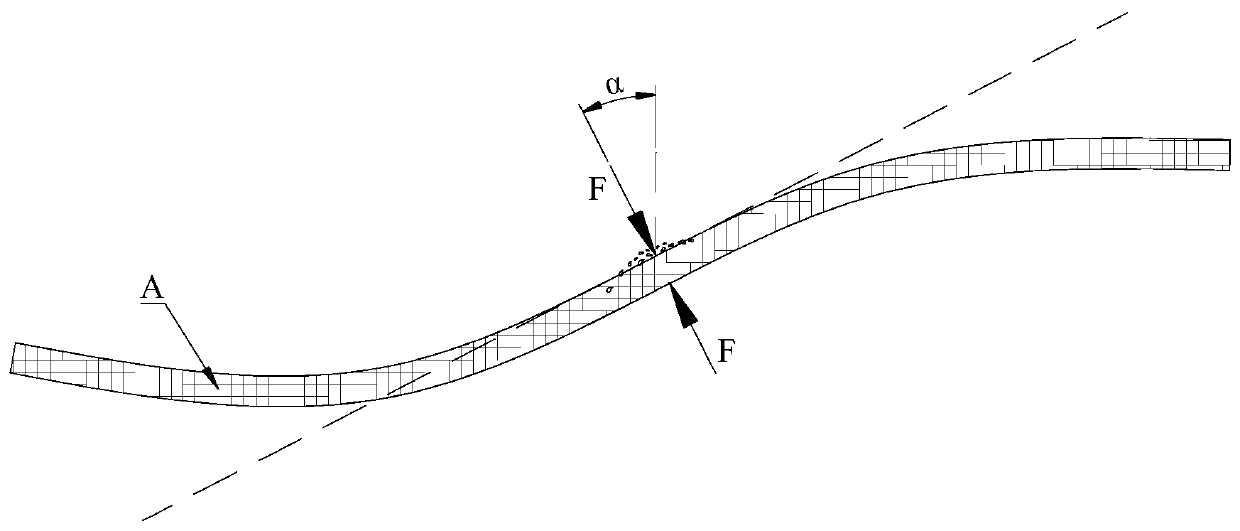

[0059] Such as figure 1 As shown, step S1 abandons the method of extruding the tire base fabric ...

Embodiment 2

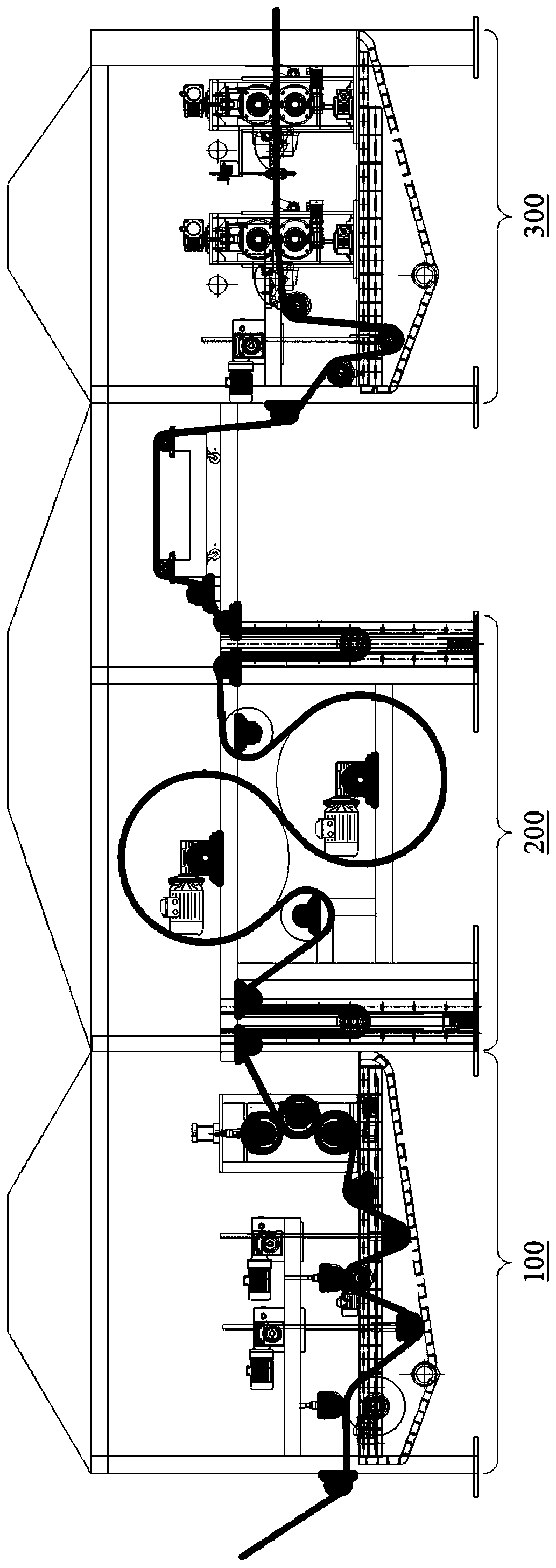

[0062] Such as image 3 As shown, a system for dipping asphalt includes a prepreg device 100 , a drying device 200 and a coating device 300 arranged in sequence.

[0063] The prepreg device 100 includes a prepreg tank 110 for holding asphalt and dipping the base fabric with asphalt, and an extrusion mechanism arranged above the prepreg tank 110 to squeeze the base fabric dipped in asphalt 120.

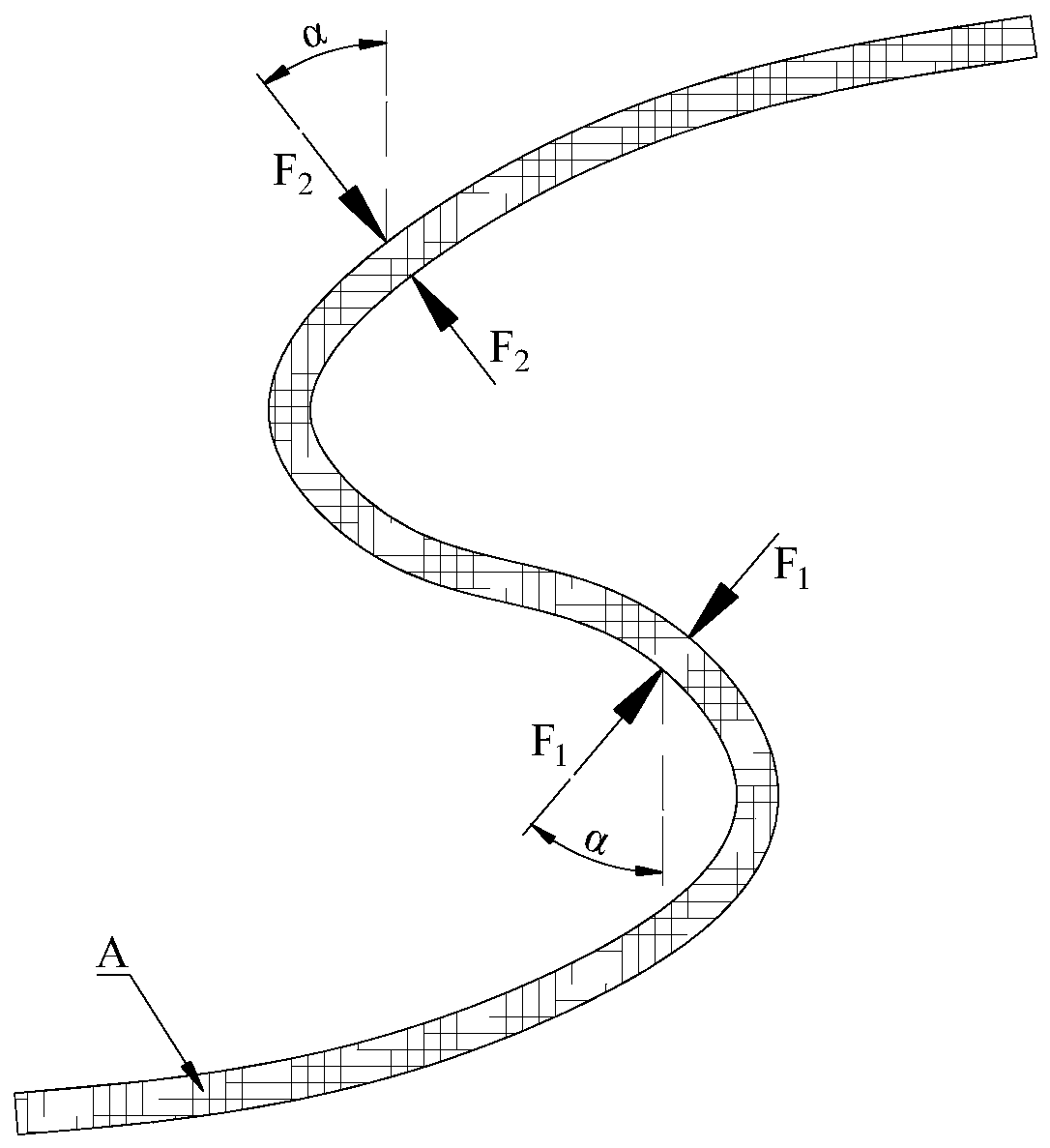

[0064] The extruding mechanism 120 includes at least two extruding rollers 121, the rotation axes of the adjacent two extruding rollers 121 are parallel to each other but not in the same vertical plane, and the tire base fabric is dipped in the prepreg tank 110 after being dipped with asphalt from the corresponding The lower sides of the two adjacent squeeze rollers 121 penetrate into the gap between the two adjacent squeeze rollers 121 . Such as Figure 5 As shown, two adjacent extrusion rollers 121 form an extrusion action on the tire base fabric passing through them, and the plac...

Embodiment 3

[0076] The difference between this embodiment and embodiment 2 is that, as Figure 11 As shown, it also includes a coating roller 131 arranged on one side of the extrusion mechanism 120 and at least partly protruding into the prepreg tank 110 to contact the asphalt. Dip the device and leave the prepreg device after passing through the coating roller 131 and the extrusion mechanism 120 in sequence. During the rotation of the coating roller 131, the asphalt in the prepreg tank 110 is brought up and coated on the subgrade passing through the coating roller 131 Cloth the lower surface. In this solution, the tire base cloth does not need to enter the asphalt in the prepreg tank 110, just cross the coating roller 131 and keep in effective contact with the coating roller 131 during this process. The lower surface of the cloth will be covered with asphalt, which will eventually form a traditional half-tire waterproofing membrane. Preferably, the surface of the coating roller 131 is ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com