Process for improving roll sticking and powder falling during rolling of negative plate

A negative electrode sheet and roll pressing technology, which is applied to battery electrodes, electrical components, circuits, etc., can solve the problems of negative electrode falling off, sticking to rolls, powder falling, etc., and achieve the effects of solving sticking rolls, improving yield and performance, and relieving stress

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

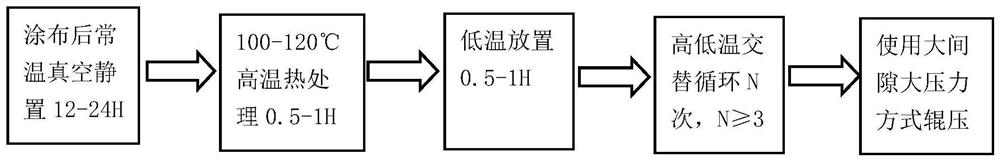

[0017] (1) Put the coated negative plate at room temperature and vacuum for 12H, preferably at room temperature of 25°C;

[0018] (2) Perform a high-temperature heat treatment at 100° C. for 0.5 hours on the negative electrode sheet after standing in an oven;

[0019] (3) Put the heat-treated negative electrode sheet into a low-temperature box for 0.5H at a low temperature, preferably at a low temperature of -15°C;

[0020] (4) Alternate (2) and (3) for N times, preferably N≥3;

[0021] (5) The negative electrode sheet treated at low temperature after circulation is rolled once, and the rolling method uses a large gap and high pressure method for rolling. Example 2

Embodiment 2

[0022] (1) Put the coated negative plate at room temperature and vacuum for 12H, preferably at room temperature of 25°C;

[0023] (2) Perform a high-temperature heat treatment at 110° C. for 0.5 hours on the negative electrode sheet after standing in an oven;

[0024] (3) Put the heat-treated negative electrode sheet into a low-temperature box for 0.5-1H at a low temperature, preferably at a low temperature of -20°C;

[0025] (4) Alternate (2) and (3) for N times, preferably N≥3;

[0026] (5) The negative electrode sheet treated at low temperature after circulation is rolled once, and the rolling method uses a large gap and high pressure method for rolling.

Embodiment 3

[0028] (1) Put the coated negative plate at room temperature and vacuum for 24H, preferably at room temperature of 25°C;

[0029] (2) Perform a high-temperature heat treatment at 120° C. for 1 hour on the negative electrode sheet after standing in an oven;

[0030] (3) Put the heat-treated negative electrode sheet into a low-temperature box for 1H at a low temperature, preferably at a low temperature of -20°C;

[0031] (4) Alternate (2) and (3) for N times, preferably, N≥3;

[0032] (5) The negative electrode sheet treated at low temperature after circulation is rolled once, and the rolling method uses a large gap and high pressure method for rolling.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com