Heat-resistant non-silicon carbon fiber oiling agent as well as preparation and application thereof

A carbon fiber, non-silicon technology, applied in the field of heat-resistant non-silicon-based carbon fiber oil, can solve the problems of poor high temperature resistance, etc., achieve good stability, solve the effects of easy gelling, and excellent permeability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

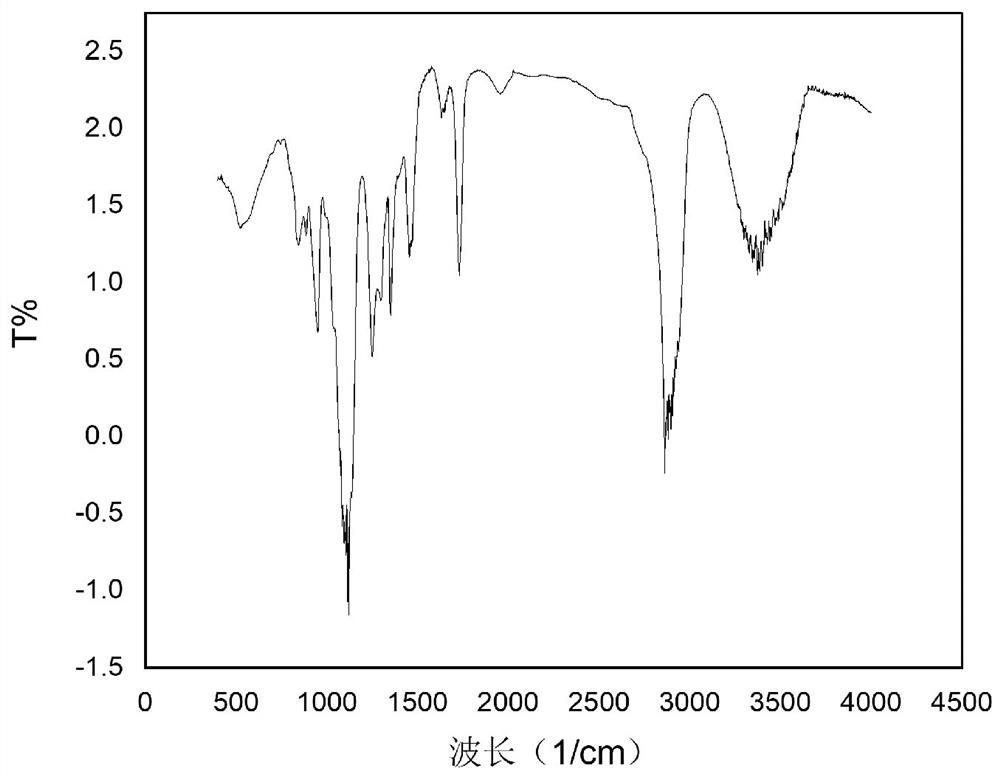

Image

Examples

Embodiment 1

[0029] Example 1: heat-resistant non-silicon carbon fiber oil

[0030] Take polyethylene glycol PEG200 and bisphenol A diether dianhydride (feeding molar ratio is 4:1) to react under nitrogen protection, the reaction temperature is 170°C, the reaction time is about 4 to 6 hours, and the hydroxyl value after the reaction is measured After reaching 50, the pressure was reduced to 1.33kpa, and the small molecular substances were gradually distilled at 90°C, and the residue was the obtained substance A.

[0031] Preparation of carbon fiber non-silicon oil agent: substance A: 10%; fatty alcohol polyoxyethylene ether AEO 9 : 8%; Didodecyldimethylammonium chloride 1%; Ethanol: 1%; Antistatic agent JL-WTA: 1%, the balance is deionized water. Mix substance A, surfactant and additives, stir evenly, add deionized water dropwise, and obtain a stable emulsion through high-speed dispersion or high-pressure homogenization treatment, which is a heat-resistant non-silicon carbon fiber oil age...

Embodiment 2

[0033] Example 2: heat-resistant non-silicon carbon fiber oil

[0034] Take polyethylene glycol PEG800 and biphenyl ether dianhydride (the molar ratio of feed is 6:1) to react under nitrogen protection, the reaction temperature is 180°C, the reaction time is about 6-8 hours, and the hydroxyl value after the reaction reaches 90. , decompressed to 1.33kpa, distilled off the small molecular substances at 120°C, and the residue was the obtained substance A.

[0035] Carbon fiber oil preparation: substance A: 13%; fatty alcohol polyoxyethylene ether AEO 9 : 6%; Didodecyl dimethyl ammonium chloride (bromide) 2%; Isomerized alkyl alcohol polyoxyethylene ether 2%; Ethanol: 1%; Antistatic agent JL-WTA: 1%, remaining The volume is deionized water. After mixing and stirring substance A, surfactant, and additives evenly, add deionized water dropwise, and obtain a stable emulsion through high-speed dispersion or high-pressure homogenization treatment, which is a heat-resistant non-silico...

Embodiment 3

[0037] Example 3: heat-resistant non-silicon carbon fiber oil

[0038] Take polyethylene glycol PEG400 and pyrophthalic anhydride (mole ratio: 6:1) to react under nitrogen protection, the reaction temperature is 160°C, the reaction time is about 6-8 hours, and the hydroxyl value reaches 60 after the measurement. The pressure was reduced to 1.33kPa, and the small molecular substances were distilled off at a temperature of 60°C, and the residue was the obtained substance A.

[0039] Carbon fiber oil preparation: substance A: 13%; fatty alcohol polyoxyethylene ether AEO 10 : 7%; isomerized alkyl alcohol polyoxyethylene ether 2%; ethanol: 1%; antistatic agent JL-WTA: 1%, and the balance is deionized water. After mixing and stirring substance A, surfactant, and additives evenly, add deionized water dropwise, and obtain a stable emulsion through high-speed dispersion or high-pressure homogenization treatment, which is a heat-resistant non-silicon-based oil agent.

[0040] It is pr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com