Low-intensity fumigation flavoring reconstituted tobacco capable of prolonging flavor holding time and preparation method thereof

A technology of reconstituted tobacco leaves and fragrance retention time, which is applied in the field of preparation of the reconstituted tobacco leaves, low-intensity fumigation and flavoring to prolong the fragrance retention time, can solve the problems of unused reconstituted tobacco leaves, etc., achieve long-lasting fragrance time, reduce the amount of miscellaneous gas, fruit Distinctive effect of aroma characteristics

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

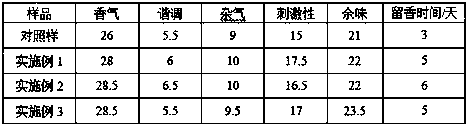

Examples

Embodiment 1

[0029] The method for preparing reconstituted tobacco leaves by low-intensity fumigation and flavoring to prolong the fragrance retention time of this embodiment includes the following steps:

[0030] Step (1), sealing treatment

[0031] Weigh the ripe fruit with strong aroma, place the fruit in a sealed bag, and exhaust the air in the sealed bag. The fruit is 4 mangoes.

[0032] Step (2), fruit fermentation

[0033] Place the sealed bag in step (1) in an incubator at 33°C, and seal it for natural fermentation for 6 days;

[0034] Step (3), reconstituted tobacco shreds

[0035] Take 20g of finished reconstituted tobacco leaves with a moisture content of less than 11% and cut them into shreds with a width of 0.8mm and a length of 2cm, and place them in a petri dish;

[0036] Step (4), low-intensity fumigation and aromatherapy

[0037] Take out the sealed bag of step (2) from the incubator, take out the fermented fruit, and quickly place the petri dish containing the shredd...

Embodiment 2

[0042] The method for preparing reconstituted tobacco leaves by fumigation and flavoring to prolong the fragrance retention time of the present embodiment comprises the following steps:

[0043] Step (1), sealing treatment

[0044] Weigh the ripe fruit with strong aroma, place the fruit in a sealed bag, and exhaust the air in the sealed bag. The fruits are 3 mangoes and 1 pineapple.

[0045] Step (2), fruit fermentation

[0046] Place the sealed bag in step (1) in an incubator at 26°C, and seal it for natural fermentation for 4 days;

[0047] Step (3), reconstituted tobacco shreds

[0048] Take 28g of finished reconstituted tobacco leaves with a moisture content of less than 11% and cut them into shreds, with a width of 1.0 mm and a length of 4 cm, and place them in a petri dish;

[0049] Step (4), low-intensity fumigation and aromatherapy

[0050] Take out the sealed bag of step (2) from the incubator, take out the fermented fruit, and quickly place the petri dish contai...

Embodiment 3

[0055] The method for preparing reconstituted tobacco leaves by fumigation and flavoring to prolong the fragrance retention time of the present embodiment comprises the following steps:

[0056] Step (1), sealing treatment

[0057] Weigh the ripe fruit with strong aroma, place the fruit in a sealed bag, and exhaust the air in the sealed bag. The fruits are 2 mangoes and 4 yellow apples.

[0058] Step (2), fruit fermentation

[0059] Place the sealed bag in step (1) in an incubator at 30°C, and seal it for natural fermentation for 5 days;

[0060] Step (3), reconstituted tobacco shreds

[0061] Take 15g of finished reconstituted tobacco leaves with a moisture content of less than 11% and cut them into shreds with a width of 1.0 mm and a length of 1.5 cm, and place them in a petri dish;

[0062] Step (4), fumigation and fragrance

[0063] Take out the sealed bag of step (2) from the incubator, take out the fermented fruit, and quickly place the petri dish containing the shr...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Width | aaaaa | aaaaa |

| Length | aaaaa | aaaaa |

| Quality | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com