3D printed vamp, sports shoe made of same and method

A technology of 3D printing and printing shoes, which is applied in the field of sports shoes, can solve the problems that affect the life of sports shoes, complex uppers, poor packaging, etc., and achieve the effects of light weight, improved durability, and good stretching force

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach

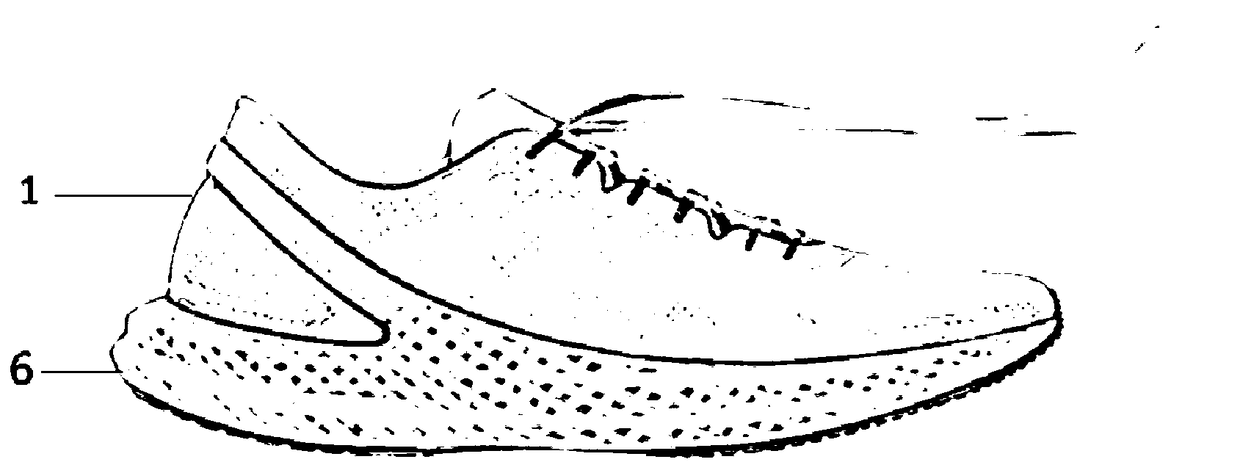

[0033] The preferred embodiment of the 3D printing vamp of the present invention and the sports shoes and method thereof are as follows:

[0034] 3D printed upper:

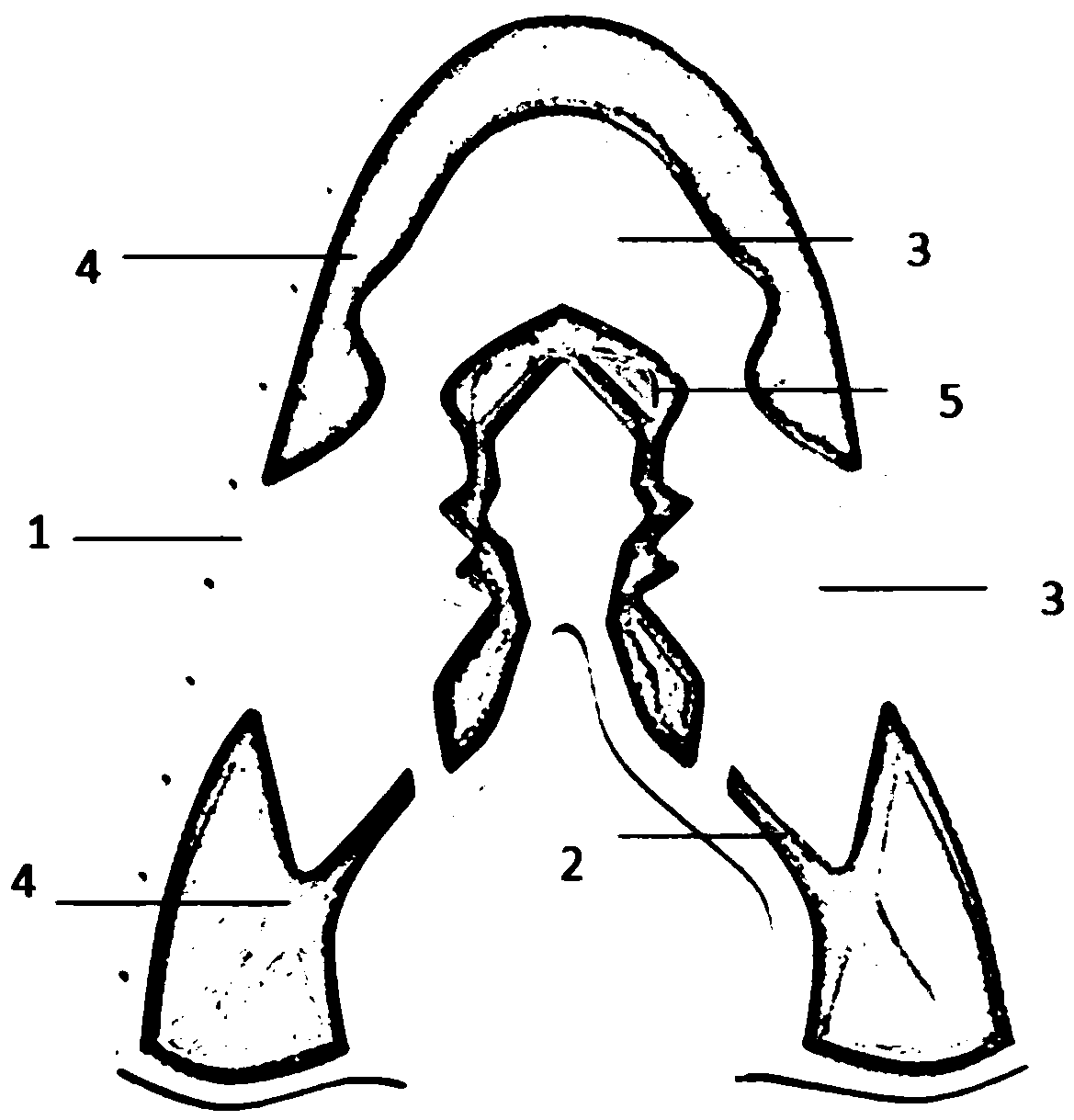

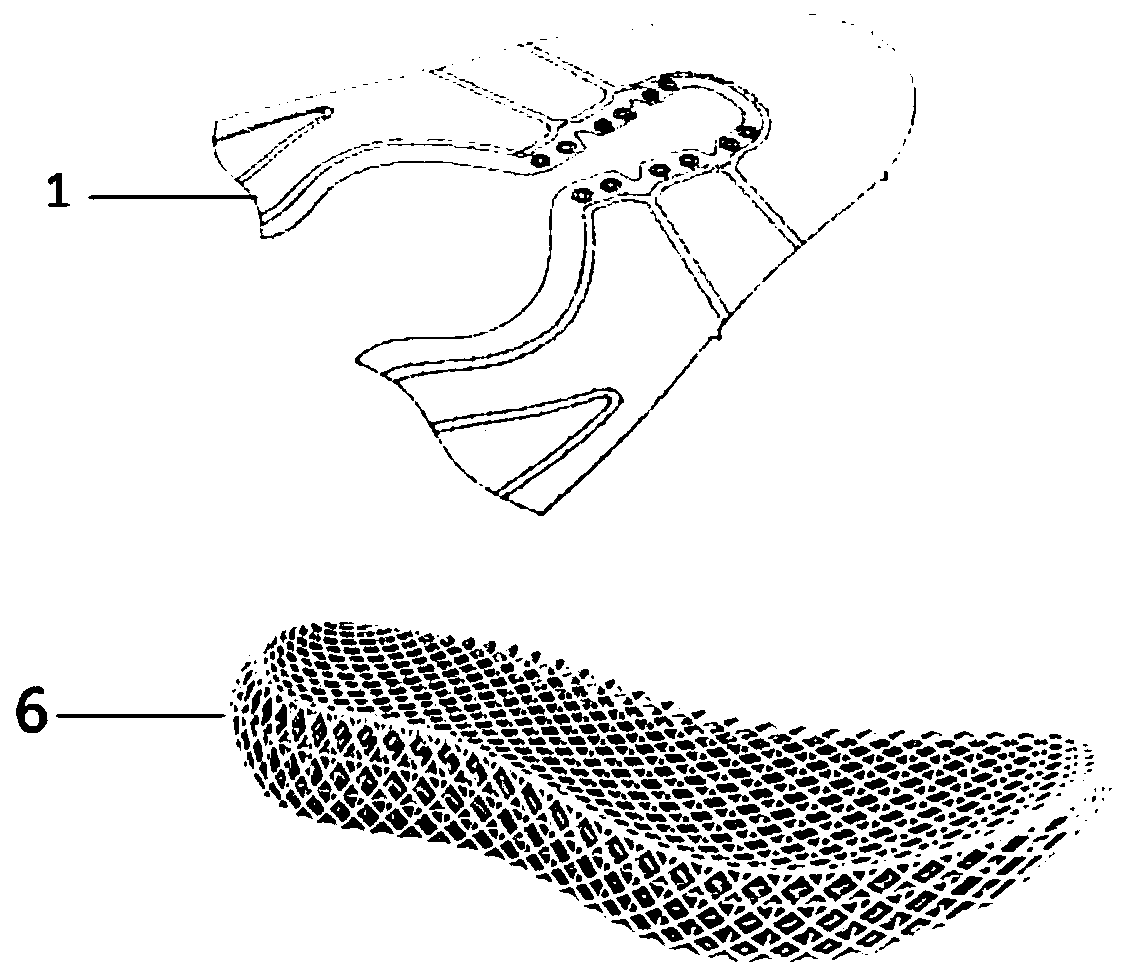

[0035] Print 1-2 layers of 3D printed fabric on the front of the instep, the inner and outer sides of the arch, print 3-4 layers of 3D printed fabric on the toes, ankles, and heels, and print 1 layer of 3D printed fabric on other parts. The 3D printed fabric is provided with hollowed-out ventilation.

[0036] The lines of the 3D printed fabric at the ankle joint are arranged along the direction of the force of the foot movement, and the 3D printed fabrics at other parts are connected by interlaced lines of warp and weft.

[0037] There are 3D printed diverse decorative patterns on the part where the shoelaces are tied on the instep.

[0038] The raw material of the 3D printed upper is TPU wire.

[0039] The line thickness of the 3D printing fabric is not more than 0.3mm.

[0040] Sports shoes made of the above...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com