Tool for machining inverted cone characteristics of turbine blade

A technology of steam turbine blades and inverted cones, which is applied in the direction of manufacturing tools, metal processing equipment, milling cutters, etc., can solve the problems of high processing cost, low processing efficiency, and low pass rate of appearance quality, and improve processing efficiency and tool life. , The effect of eliminating the traces of the knife

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

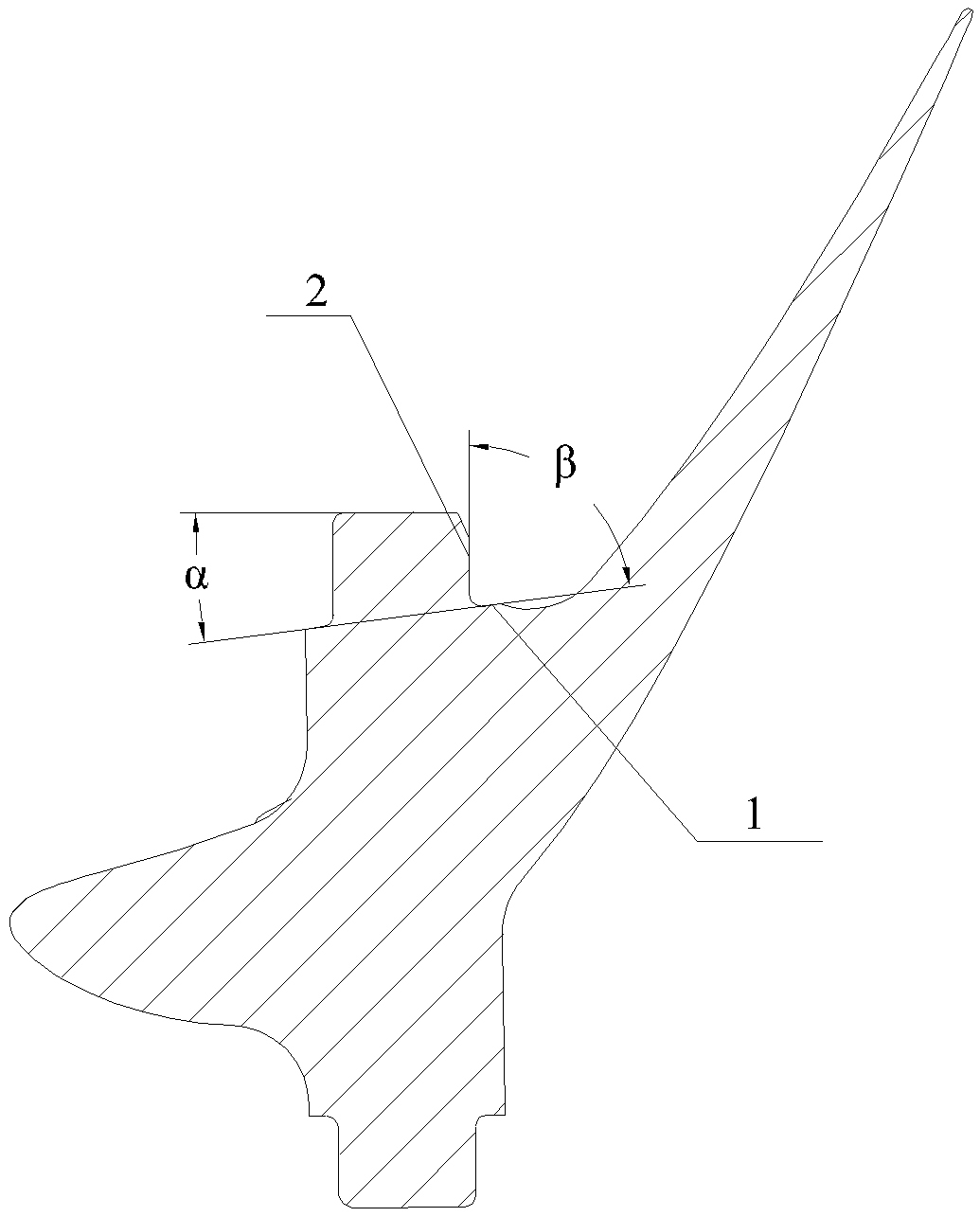

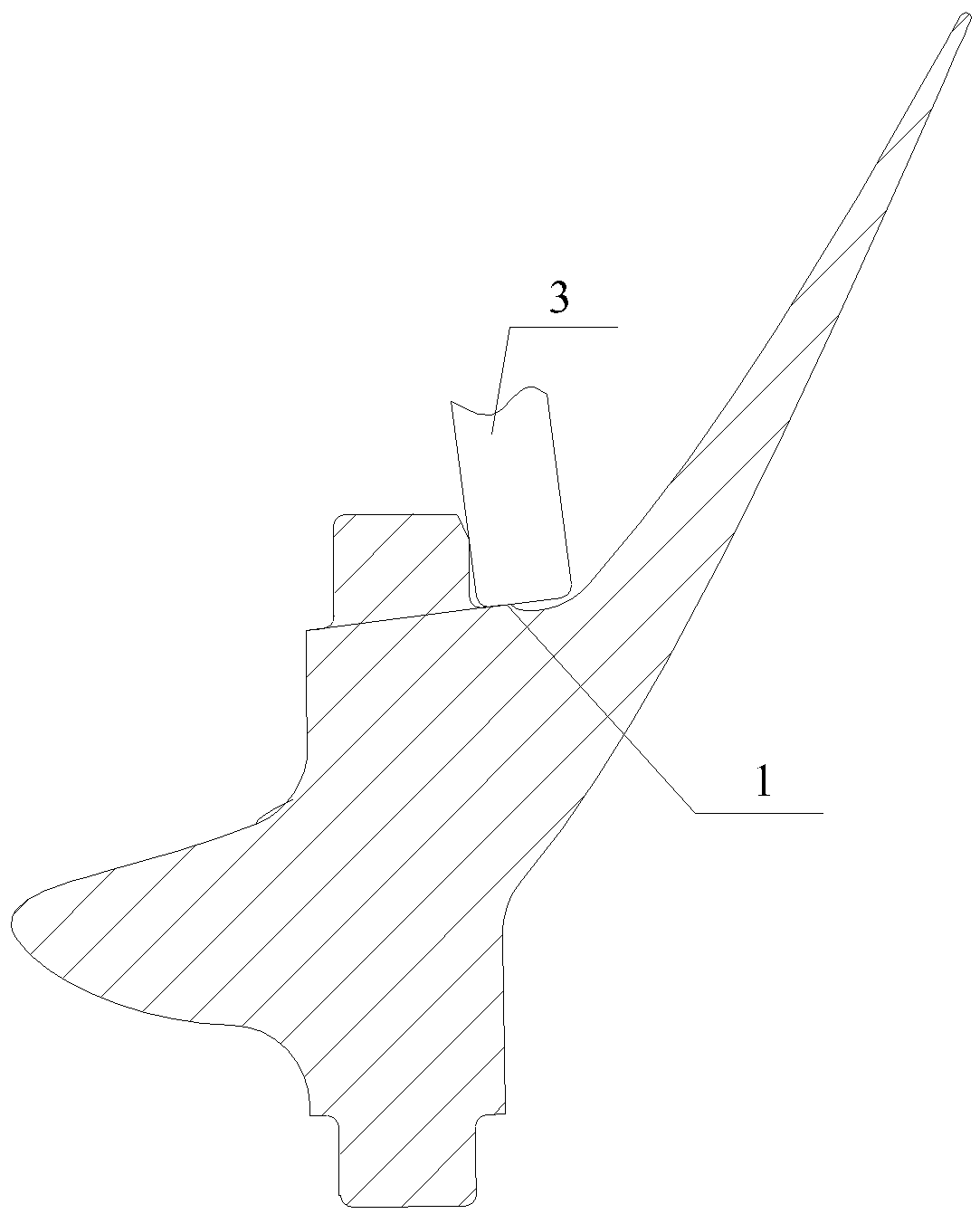

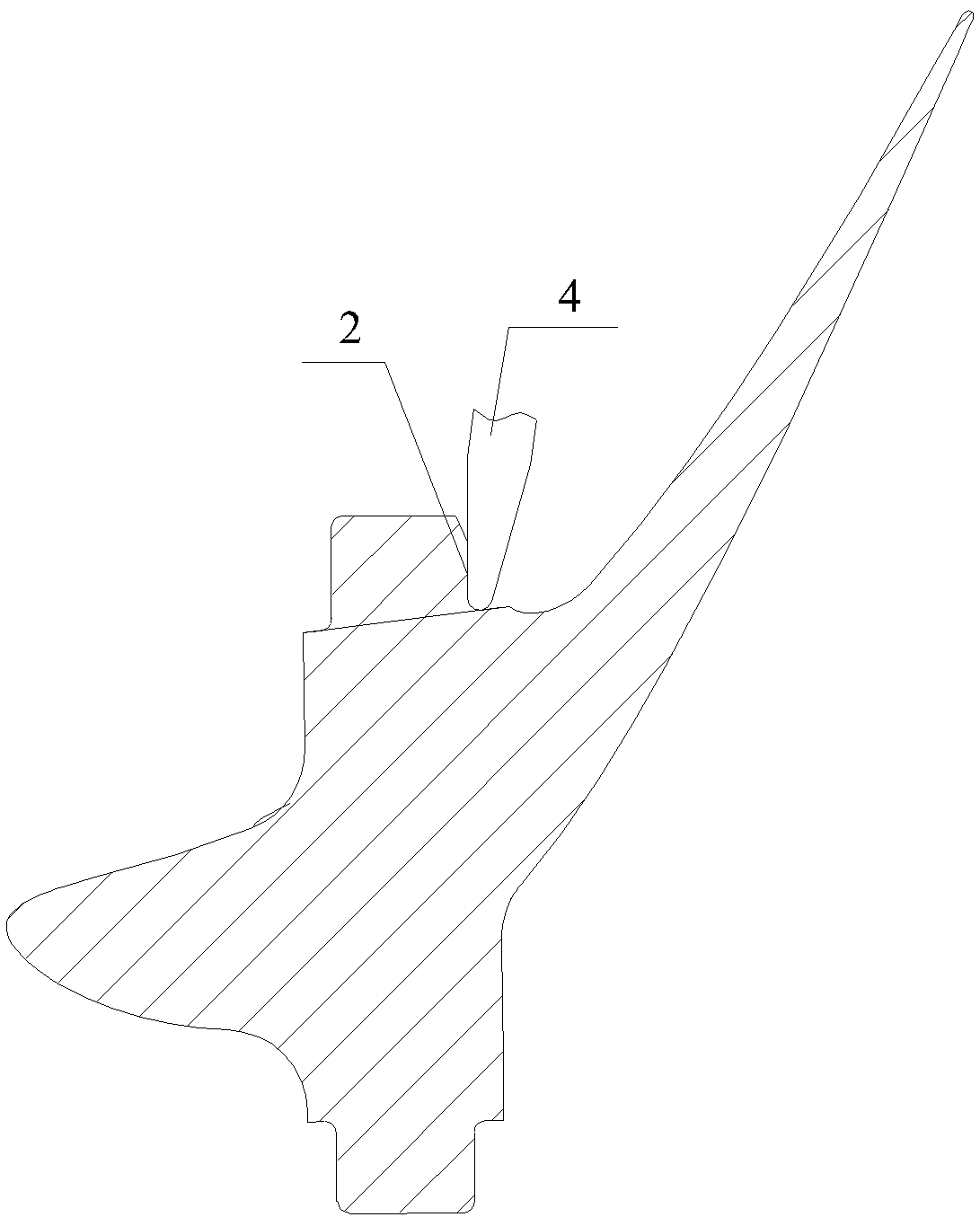

[0022] See Figure 6 to Figure 7 , a cutting tool for machining the reverse cone feature of steam turbine blades according to the present invention, which includes a standard end mill 11, the standard end mill includes a bottom edge 12 and a side edge 13, and the number of the bottom edge 12 and the side edge 13 is equal to and greater than Or equal to four, the side edge 13 is helical and the helix is a conical helix, the helix diameter of the conical helix gradually increases from the upper end of the side edge 13 to the bottom edge 12, and the half-cone angle θ of the conical helix is less than or equal to the steam turbine The back taper angle α of the boss of the blade and the height h of the side edge 13 are greater than or equal to 10 mm, which can meet the cutting processing requirements of the back taper feature. The side edge 13 is coated with a wear-resistant coating, which can improve the service life of the tool. The half-cone angle θ of the conical helix can ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Height | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com