Quick mixing process of building cement

A construction cement and process technology, which is applied in the directions of mixing operation control, raw material supply device for sale, mixing operation control device, etc., can solve the problems such as the reduction of flexural tensile capacity and cement stability, the influence of cement blocks on use, and the easy occurrence of local cracks. , to achieve good thermal insulation effect, increase mixing efficiency, and prevent damage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

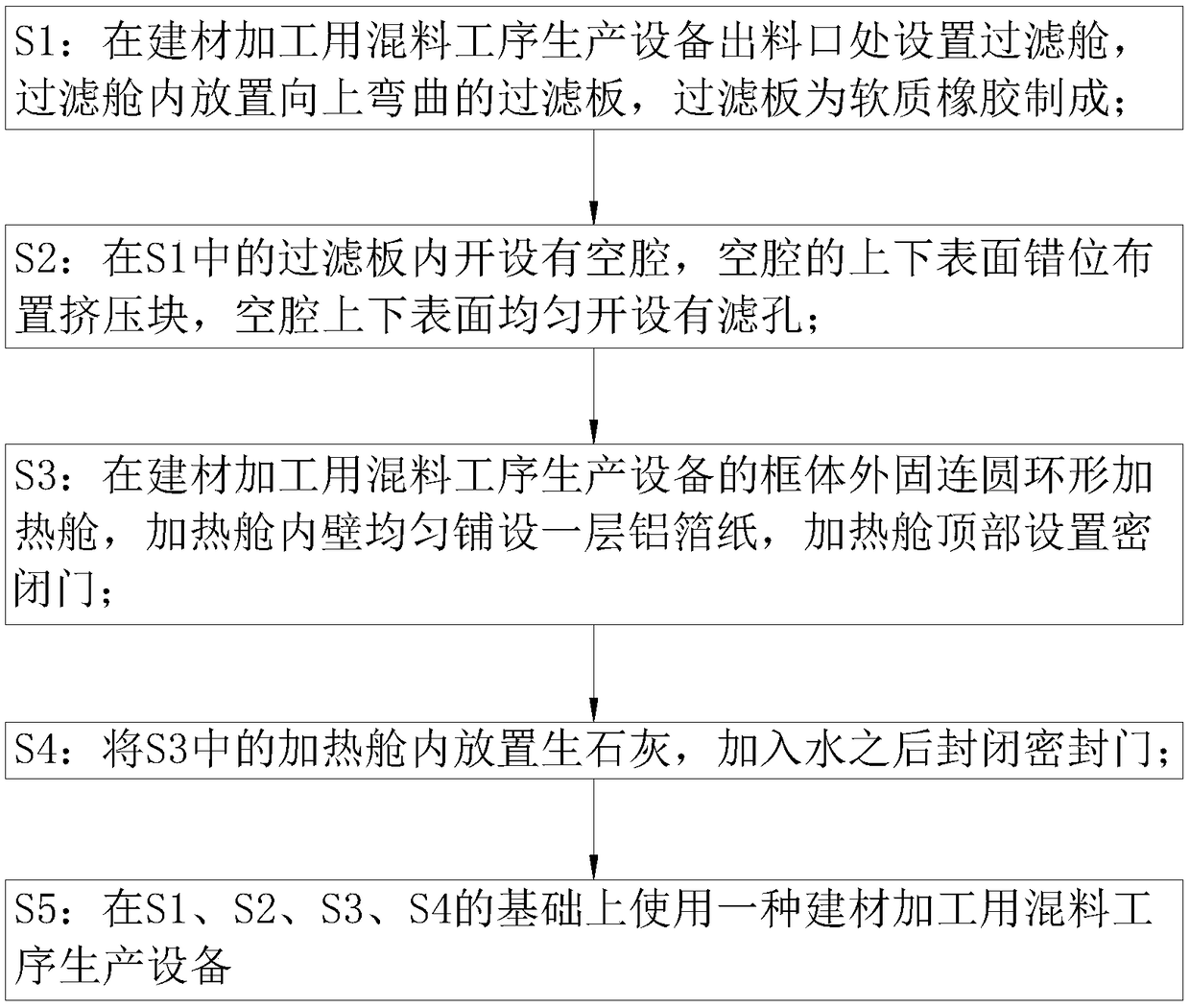

Method used

Image

Examples

Embodiment approach

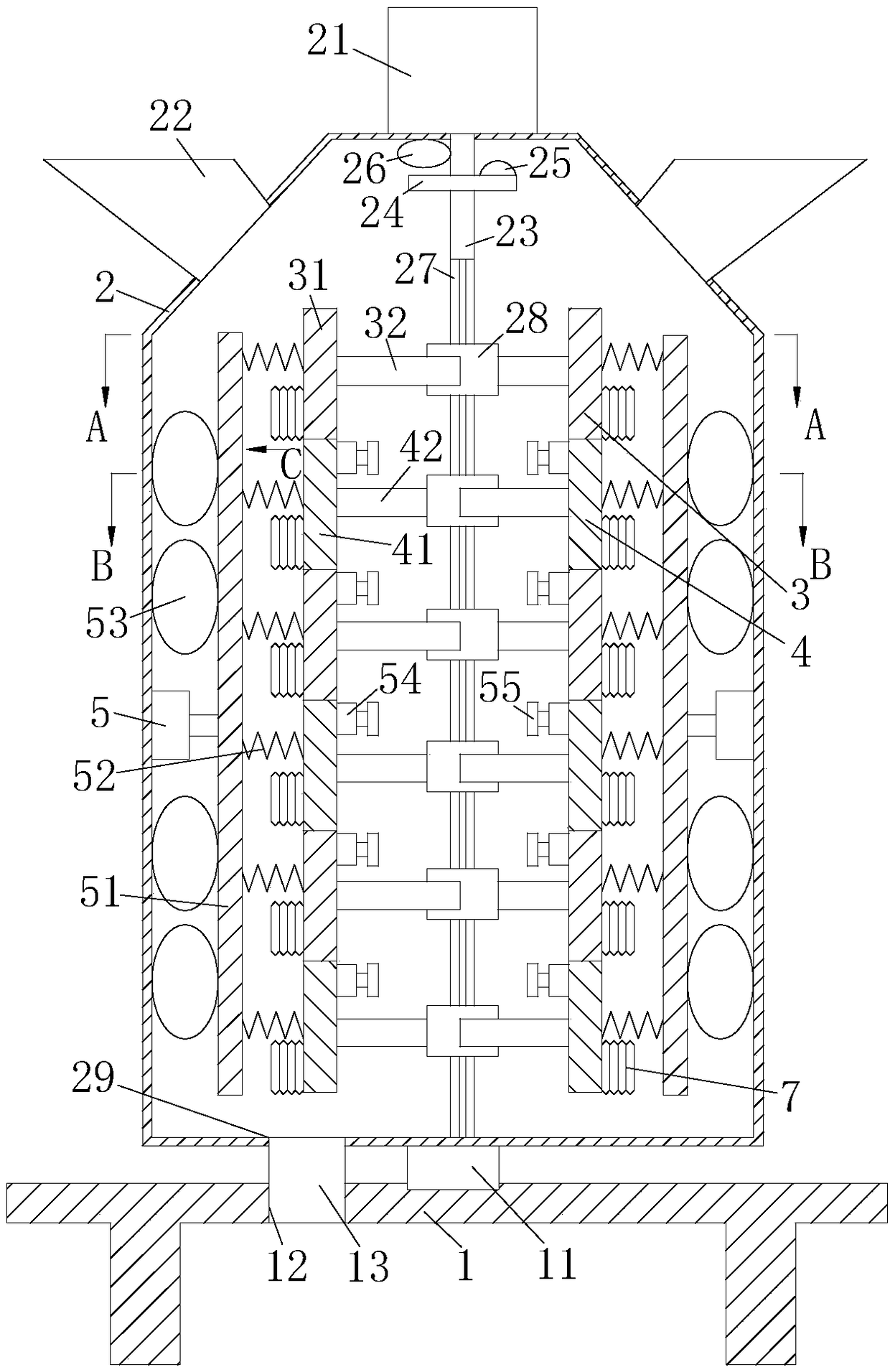

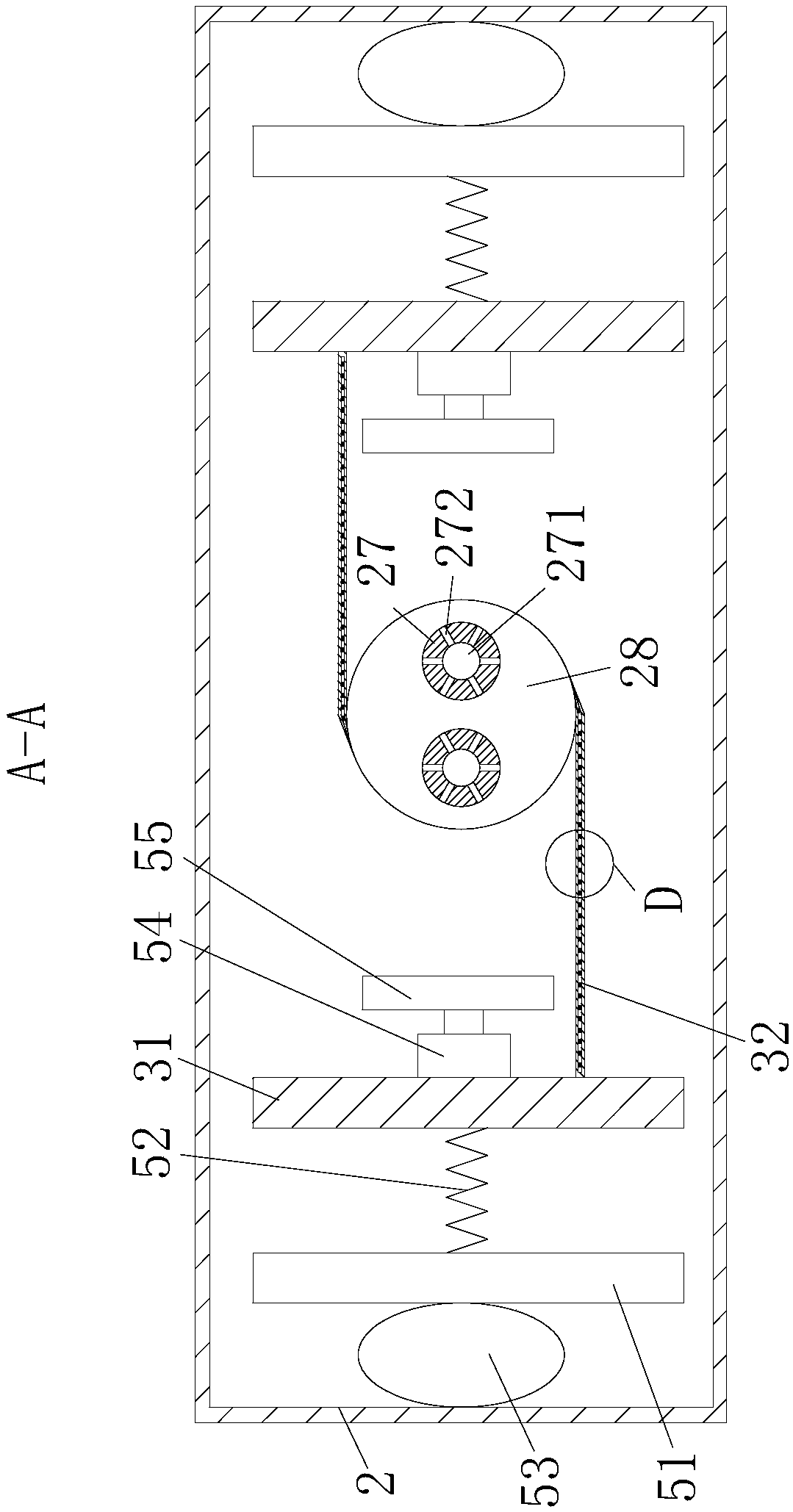

[0038] As an embodiment of the present invention, it is characterized in that: a second airbag 53 is evenly arranged between the third push plate 51 and the inner wall of the frame 2; the first push plate 31 and the second push plate 41 are close to elastic A second cylinder 54 is fixedly connected to one side of the bar 27; the second cylinder 54 is arranged horizontally, and the second cylinder 54 is in communication with the second airbag 53; the driving ends of the second cylinder 54 are fixedly connected to the Four push plate 55; the length of the fourth push plate 55 is less than the shortest distance between two adjacent discs 28; when in use, the third push plate 51 reciprocates left and right to squeeze and relax the second airbag 53, so The extended end of the second cylinder 54 extends and contracts to drive the fourth push plate 55 to reciprocate, which can mix the building materials between the discs 28, avoid the blind spots of the mixing, and make the mixing more...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com